Refrigerated container underframe structure and refrigerated container using the under-frame structure

A technology of refrigerated container and bottom frame, which is applied in the directions of packaging, transportation and packaging, and transportation of passenger cars, can solve the problems of high foaming density of foaming layer, high consumption of foaming materials, and high consumption of materials, so as to reduce the foaming density. , The effect of reducing heat leakage rate and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

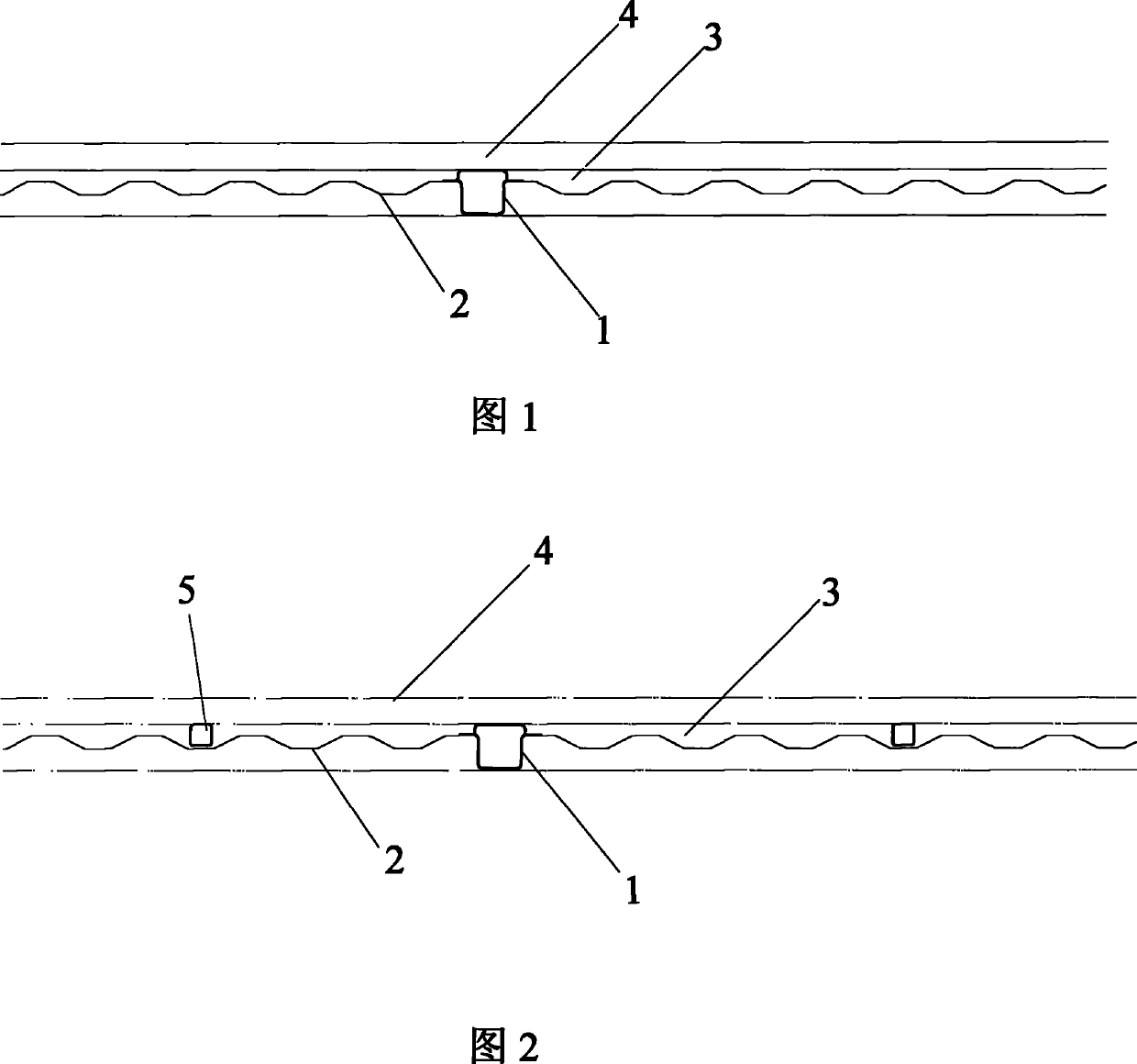

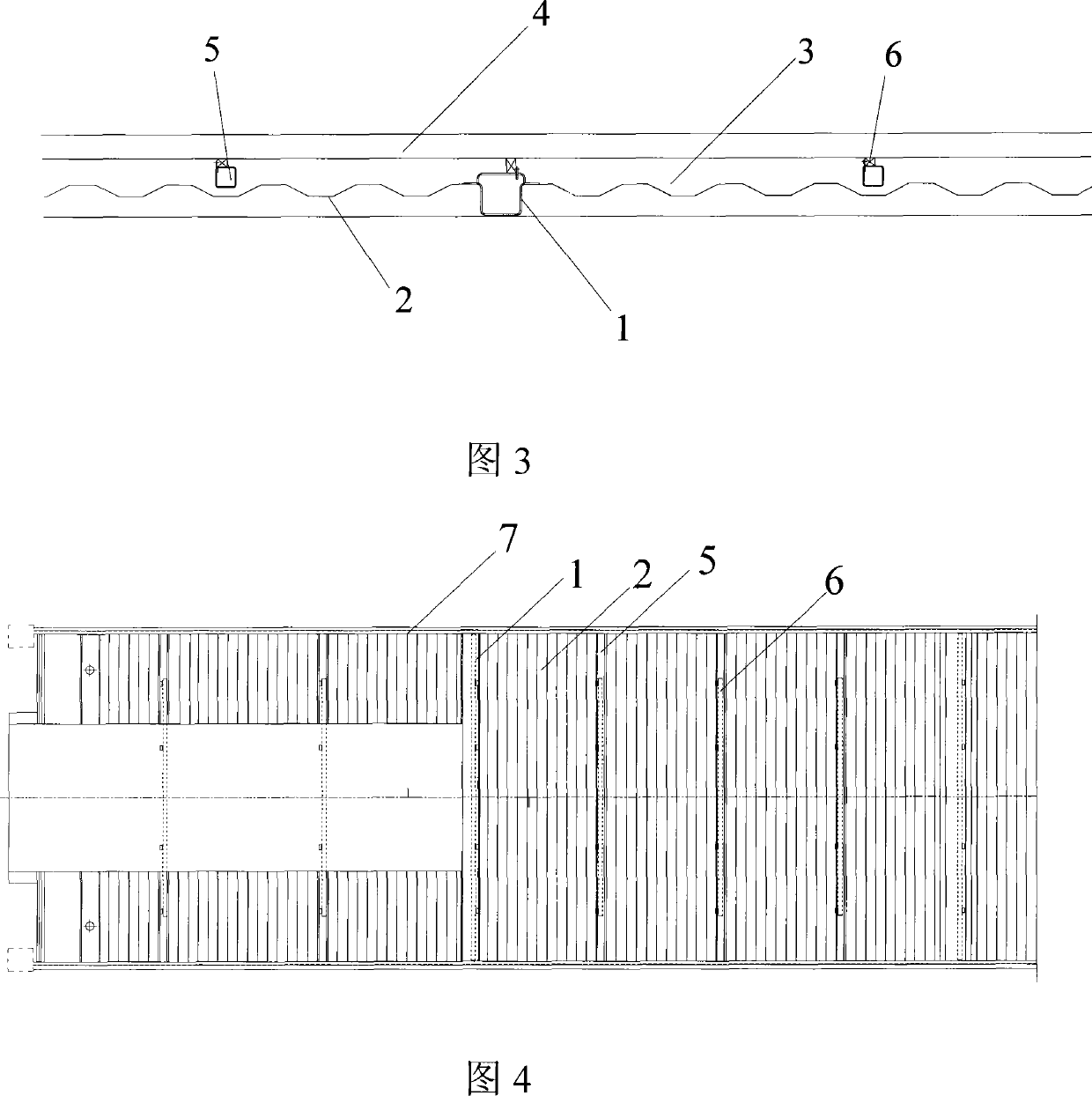

[0019] The present invention provides an underframe structure for a refrigerated container, which includes two bottom side beams 7 arranged longitudinally, a plurality of main bottom beams 1 vertically arranged on the bottom side beams, and the bottom side beams 7 and main The corrugated auxiliary floor 2 connected to the bottom beam 1, the two ends of the main bottom beam 1 are welded on the bottom side beam 7, the corrugated auxiliary floor 2 is placed on the main bottom beam, and it is characterized in that it also includes multiple small bottoms Crossbeams 5, each small bottom crossbeam 5 is placed between the trough of the corrugated sub-floor 2 and the T floor 4 in the box, and its two ends are also vertically welded on the bottom side beam 7.

[0020] As shown in FIG. 2 , in Embodiment 1 of the present invention, the underframe structure of the refrigerated container is mainly composed of two longitudinal bottom side beams 7 and multiple main bottom cross beams 1 . Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com