Combined internal thermal cooler sulfur recovery reactor

A sulfur recovery and combined technology, which is applied in the direction of sulfur preparation/purification, etc., can solve the problems of large equipment footprint and a large number of equipment, and achieve the goal of saving equipment footprint, simplifying process piping, and reducing the number of process equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

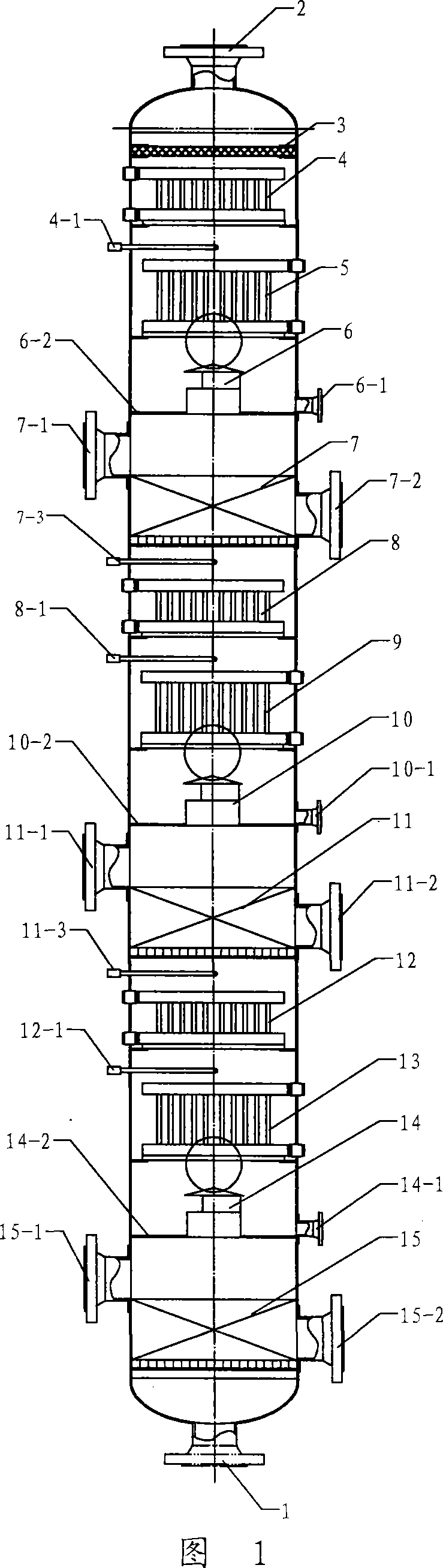

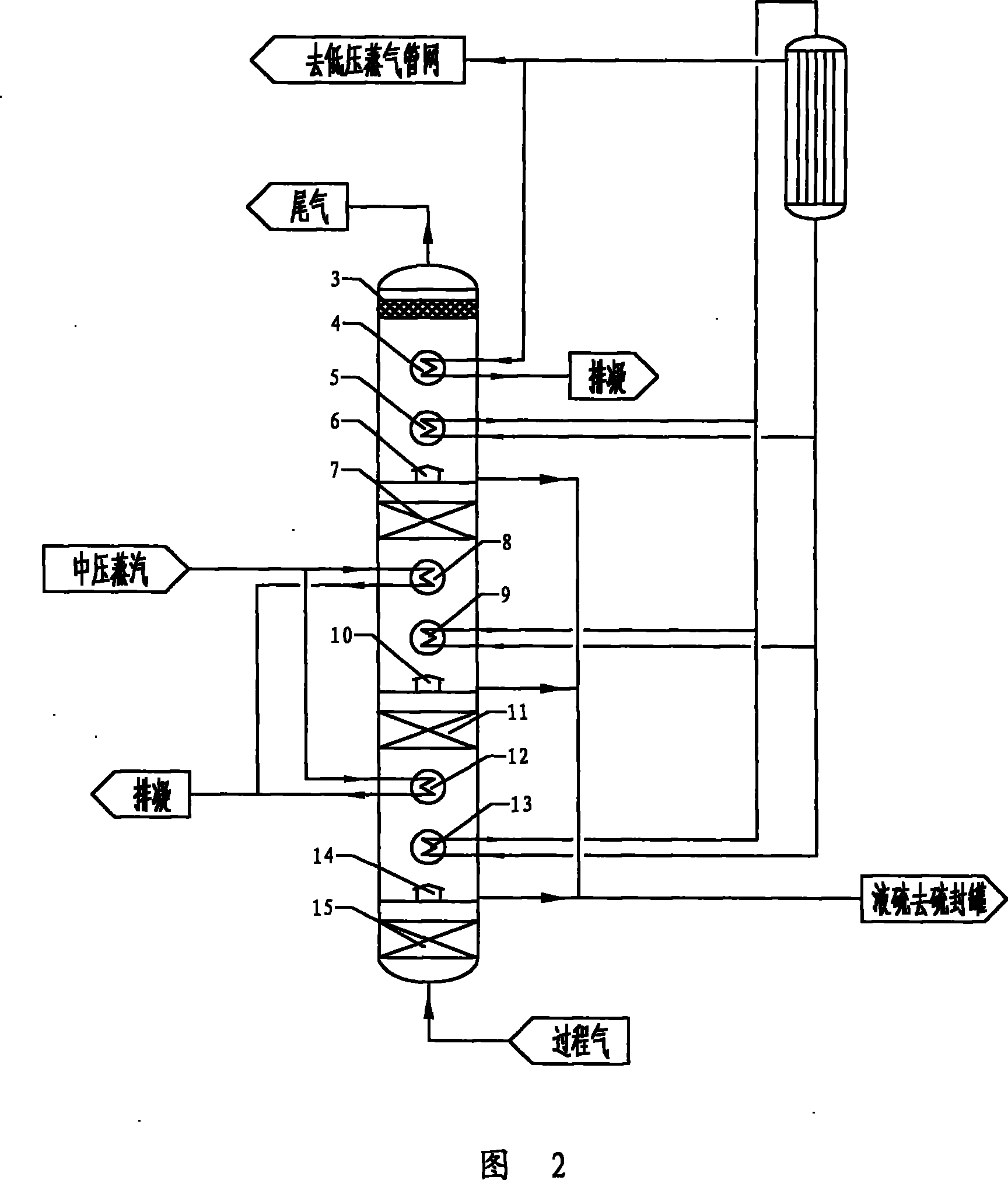

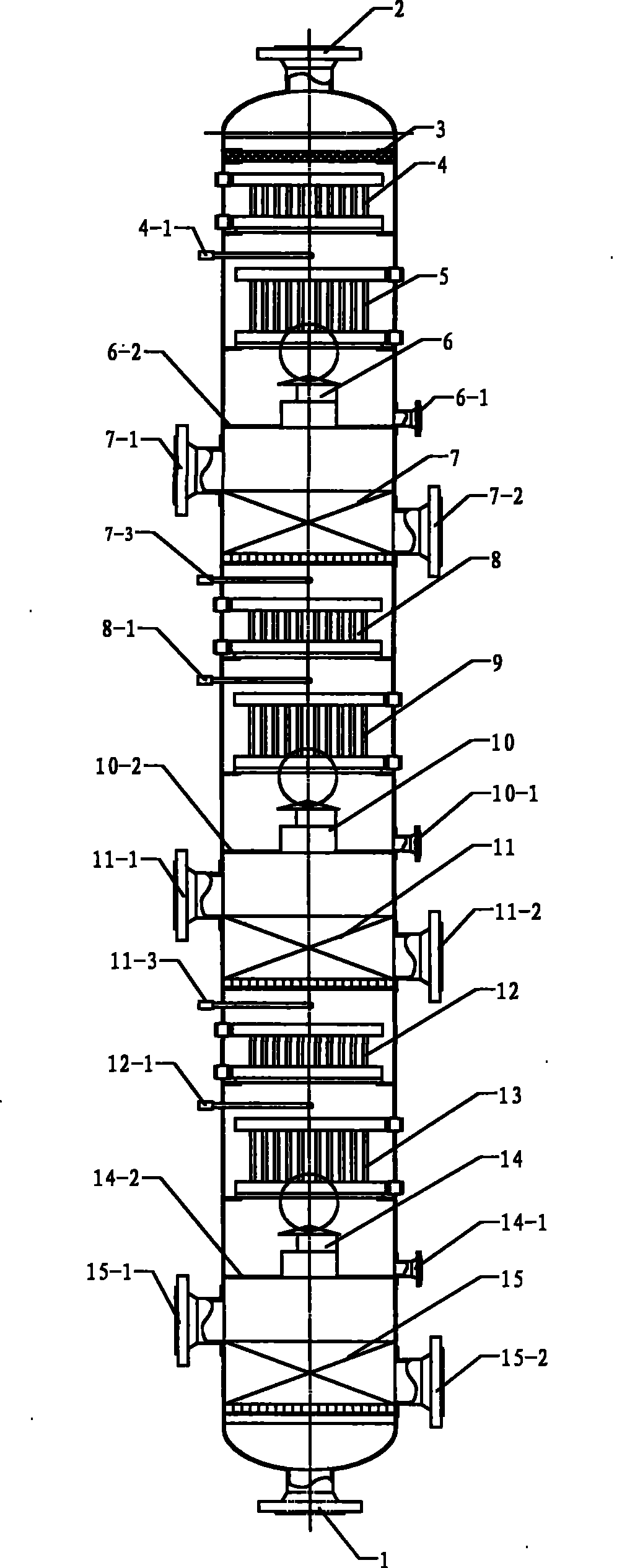

[0017] As shown in Figure 1, a combined internal heat extraction sulfur recovery reactor includes a tower body, the top of the tower body is provided with an exhaust gas outlet 2, and the bottom of the tower body is provided with a process gas inlet 1. According to the sequence of the process flow, the tower body starts from the bottom The primary reformer 15, the secondary reformer 11, and the hydrogenation reactor 7 are successively arranged at intervals at the top. Between the primary reformer 15 and the secondary reformer 11, a primary process gas heater 12, a primary condenser 13, and a baffle 14-2 are sequentially arranged from top to bottom; in order to monitor the primary process gas heater 12 , the temperature of the primary condenser 13, thermocouples 11-3, 12-1 are also set respectively; the gas-rising port 14 is set on the baffle plate 14-2, and the side wall of the tower body above the baffle plate 14-2 is provided with a liquid sulfur outlet 14 -1, the primary co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com