Warm wind blower

A blower, warm air technology, applied in air heaters, lighting and heating equipment, climate change adaptation, etc., can solve the problems of worsening fuel consumption, low heat exchange efficiency, low heat exchange rate, etc., to improve fuel consumption, increase Contact area, the effect of improving the heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

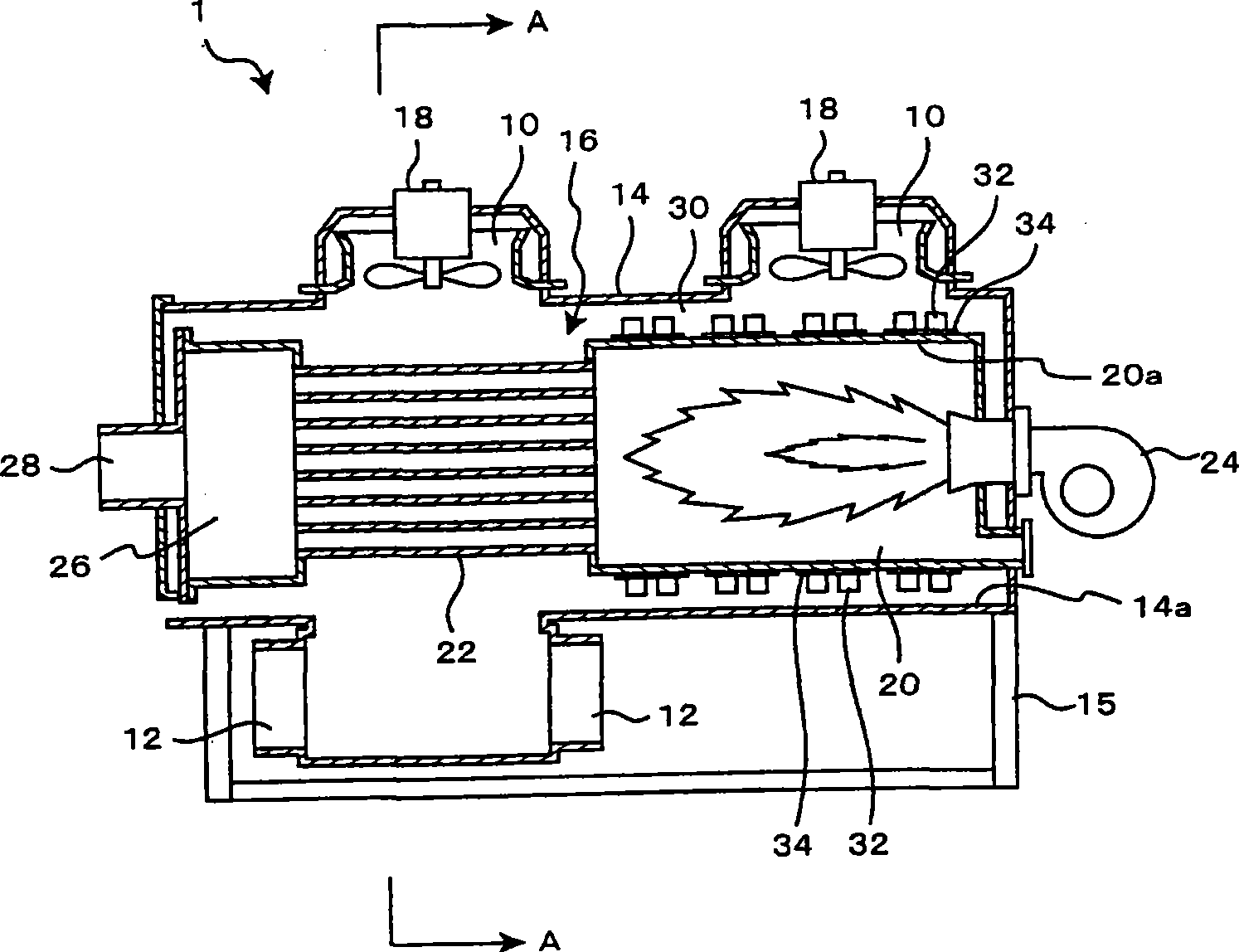

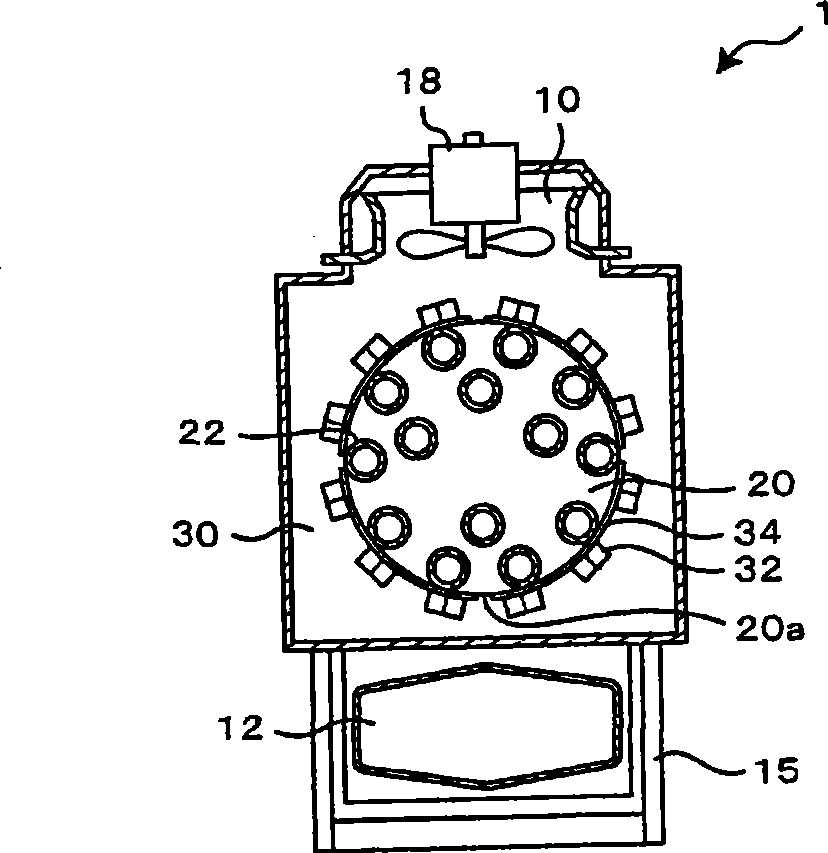

[0025] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings. figure 1 It is a side sectional view of the warm air blower according to the embodiment of the present invention, figure 2 yes figure 1 A-A sectional view of the warm air blower shown. In addition, the warm air blower according to the present embodiment may be installed in any place as long as heating is required, such as in a house for gardening or in a factory.

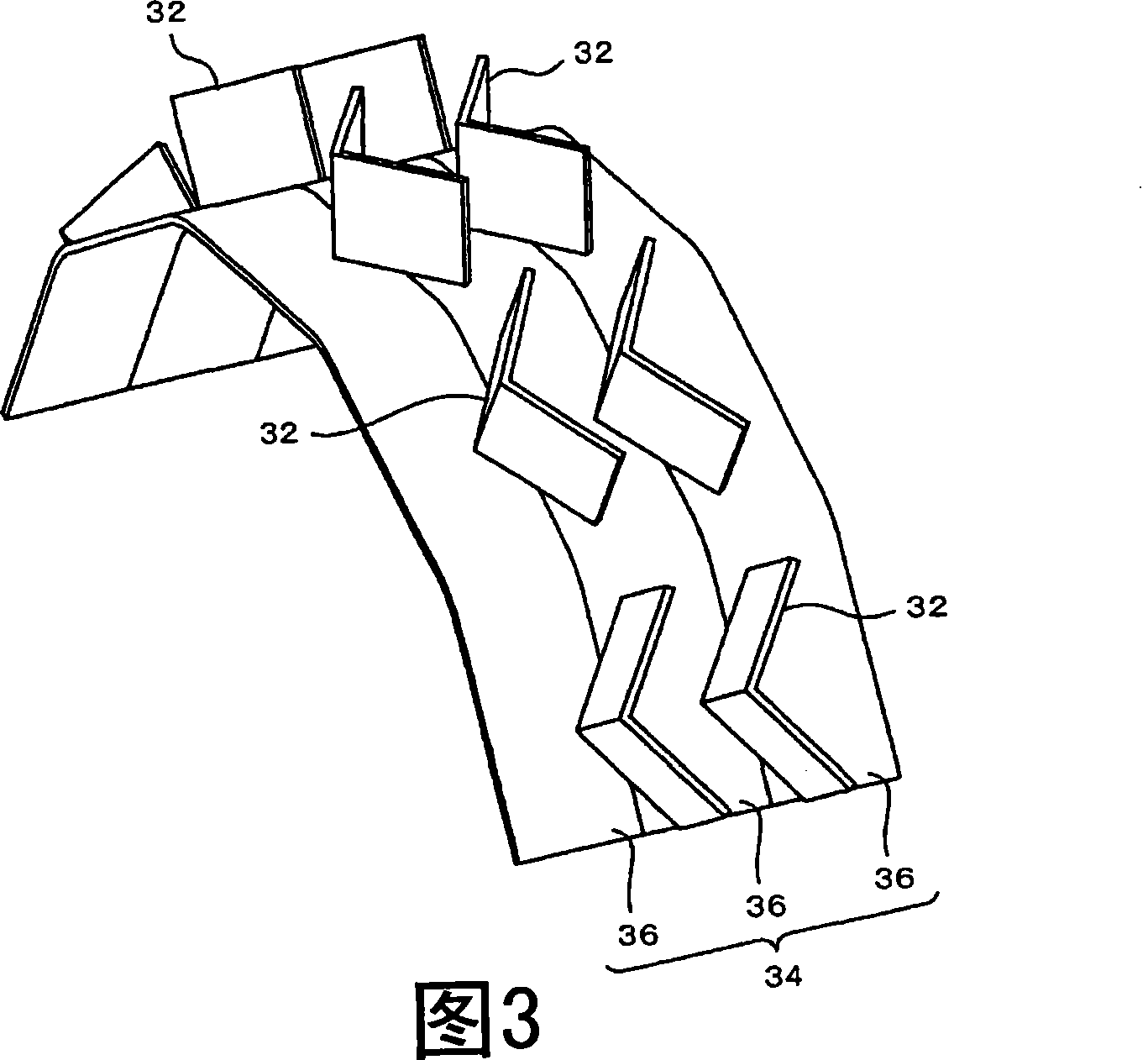

[0026] Such as figure 1 and figure 2 As shown, the warm air blower 1 according to the present embodiment includes a housing 14 having an air inlet 10 and an exhaust port 12, a heat source 16 provided in the housing 14, and a heat source 16 for sucking air from the air inlet 10 into the housing. The blower fan 18 of the blower mechanism that makes the air in the housing 14 exhaust from the exhaust port 12 in the body 14 . The heat source 16 is composed of a combustion chamber 20 and a smoke p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com