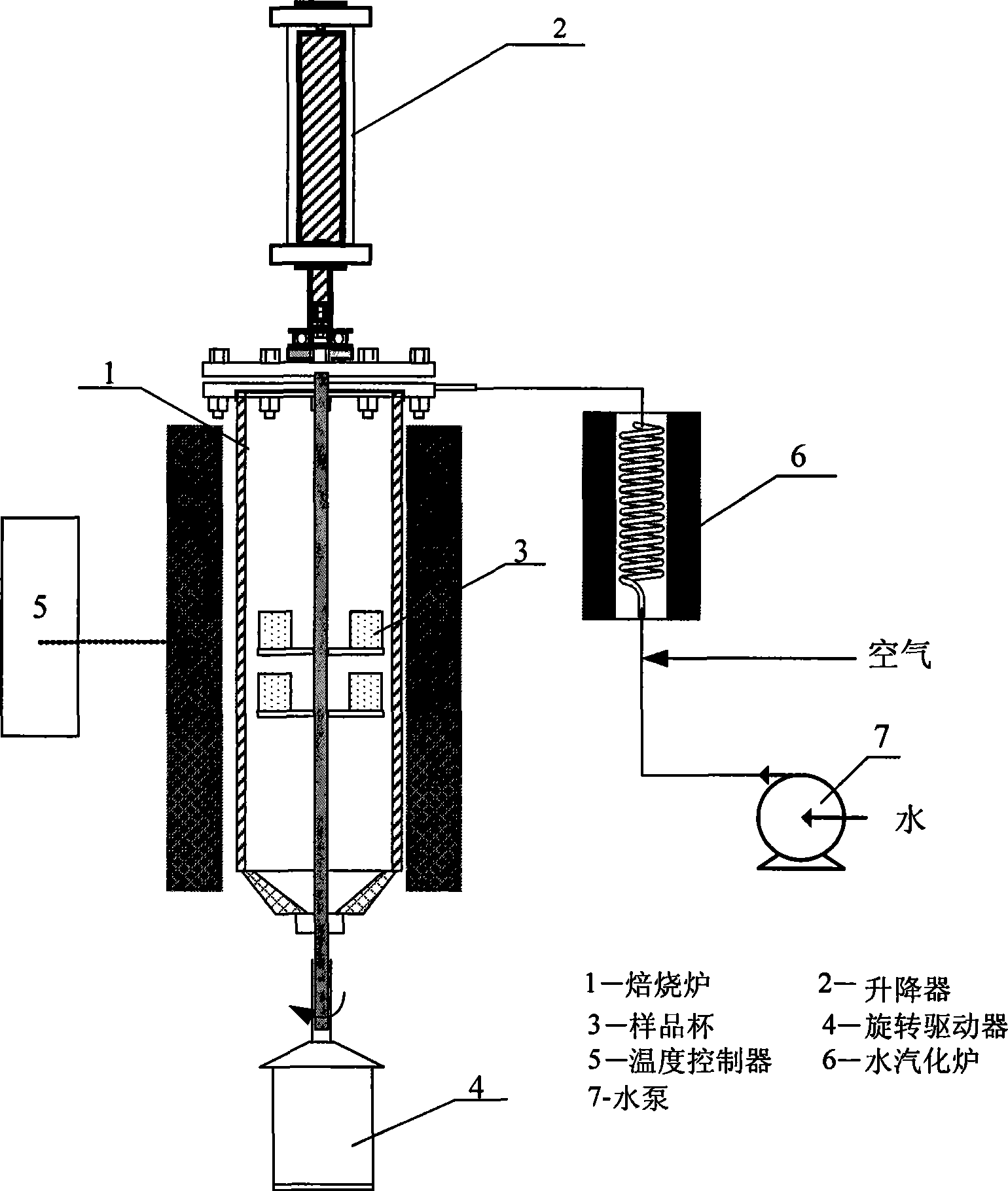

Multi-example high-temperature rotating and roasting device

A roasting device and multi-sample technology, applied in the field of multi-sample high-temperature rotary roasting devices, can solve the problems of steam channeling, different aging severity and influence of upper and lower samples, and achieve small test errors, unmanned operation, and high efficiency. Effect

Active Publication Date: 2009-05-06

北京惠尔三吉绿色化学科技有限公司

View PDF0 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This device has played an important role in improving the efficiency of catalyst evaluation tests and saving energy and manpower, but its disadvantage is that hanging baskets are arranged in series in hanging baskets, and the aging severity of the upper and lower samples is different, and the exhaust gas of the upper sample affects the lower sample. , and issues such as steam channeling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0018] This example shows that the same catalytic cracking catalyst in different sample cups has a difference of less than ±1.0 in micro-activity after aging.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a multi-sample high-temperature rotary roasting device which comprises a roasting furnace, a sample cup, a rotary driver, a temperature controller, and the like. The invention can simultaneously carry out the water heat treatment (aging) of 2 to 24 samples, improve the test efficiency, eliminate the difference of aging conditions among different samples at the same time, and improve the quality of aging tests. The aging condition is from 300 DEG C to 850 DEG C, the partial pressure of water vapor is from 0.1 MPa to 0.5 MPa (absolute), and the aging time is from 1 hour to 30 hours.

Description

technical field [0001] The invention relates to a test device, in particular to a multi-sample high-temperature rotary roasting device, which is used for heat treatment, hydrothermal treatment, hydrothermal aging, hydrothermal superstability and other deactivation processes of samples such as molecular sieves, catalysts and adsorbents. Background technique [0002] Heat treatment or hydrothermal treatment is an important method for preparing molecular sieves, adsorbents and catalysts. The most conventional heat treatment device is a muffle furnace. However, those skilled in the industry know that there are problems with the temperature control accuracy of the muffle furnace and the temperature uniformity during multi-sample processing. In the process of industrial use of general molecular sieves or catalysts, the activity decays slowly, and the laboratory can only use more severe conditions to simulate the decay of industrial processes, so as to develop better catalysts faste...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N1/28

Inventor 张瑞驰李顺利俞祥麟马燕青曹兰花孙艳波

Owner 北京惠尔三吉绿色化学科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com