Point defects repairing method of lcd device

A technology of a liquid crystal display device and a repair method, applied in nonlinear optics, instruments, optics, etc., can solve the problems of difficult to repair continuous point defects, out of specification, bright spot defects can only be repaired into dark spot defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

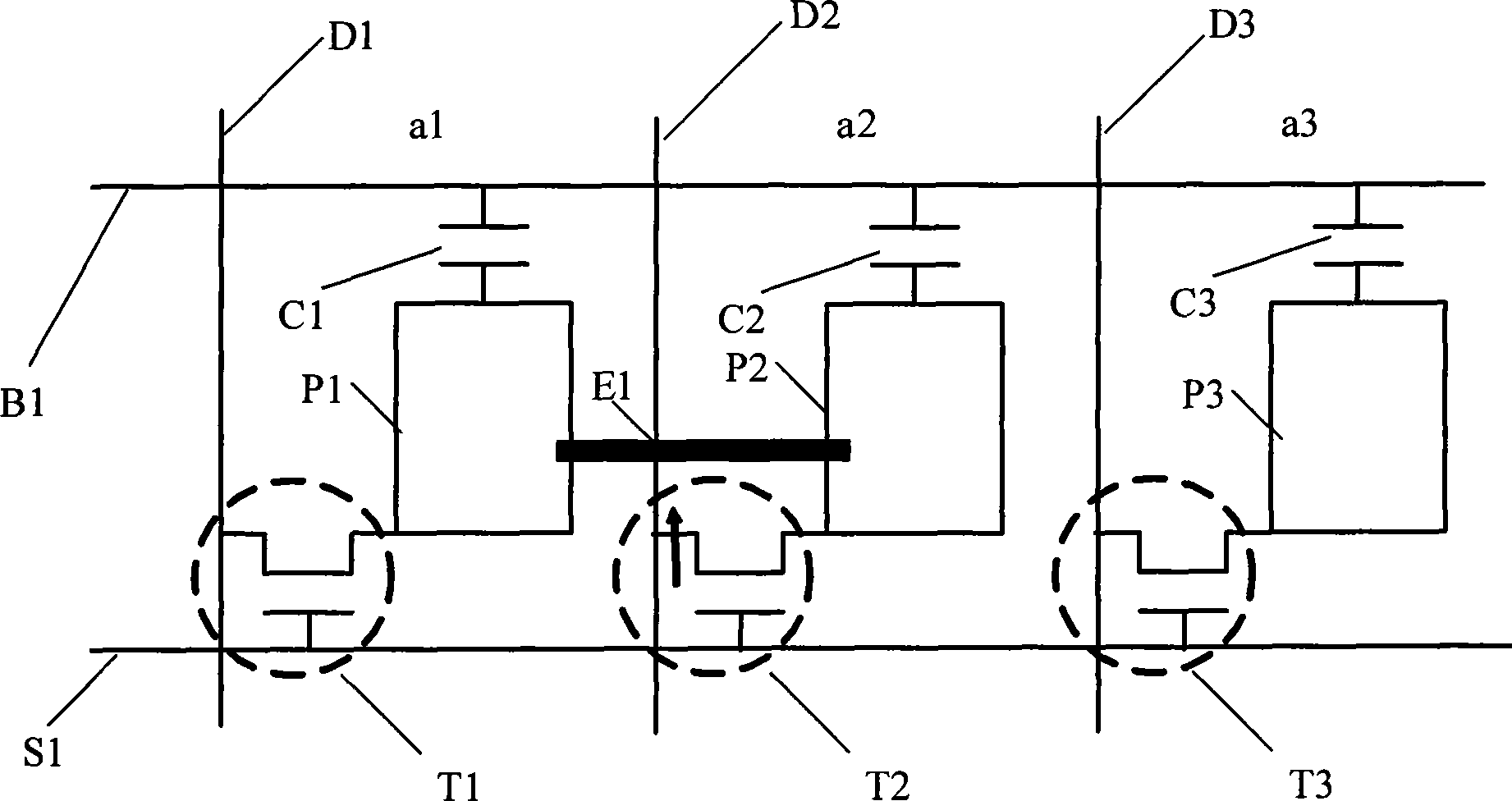

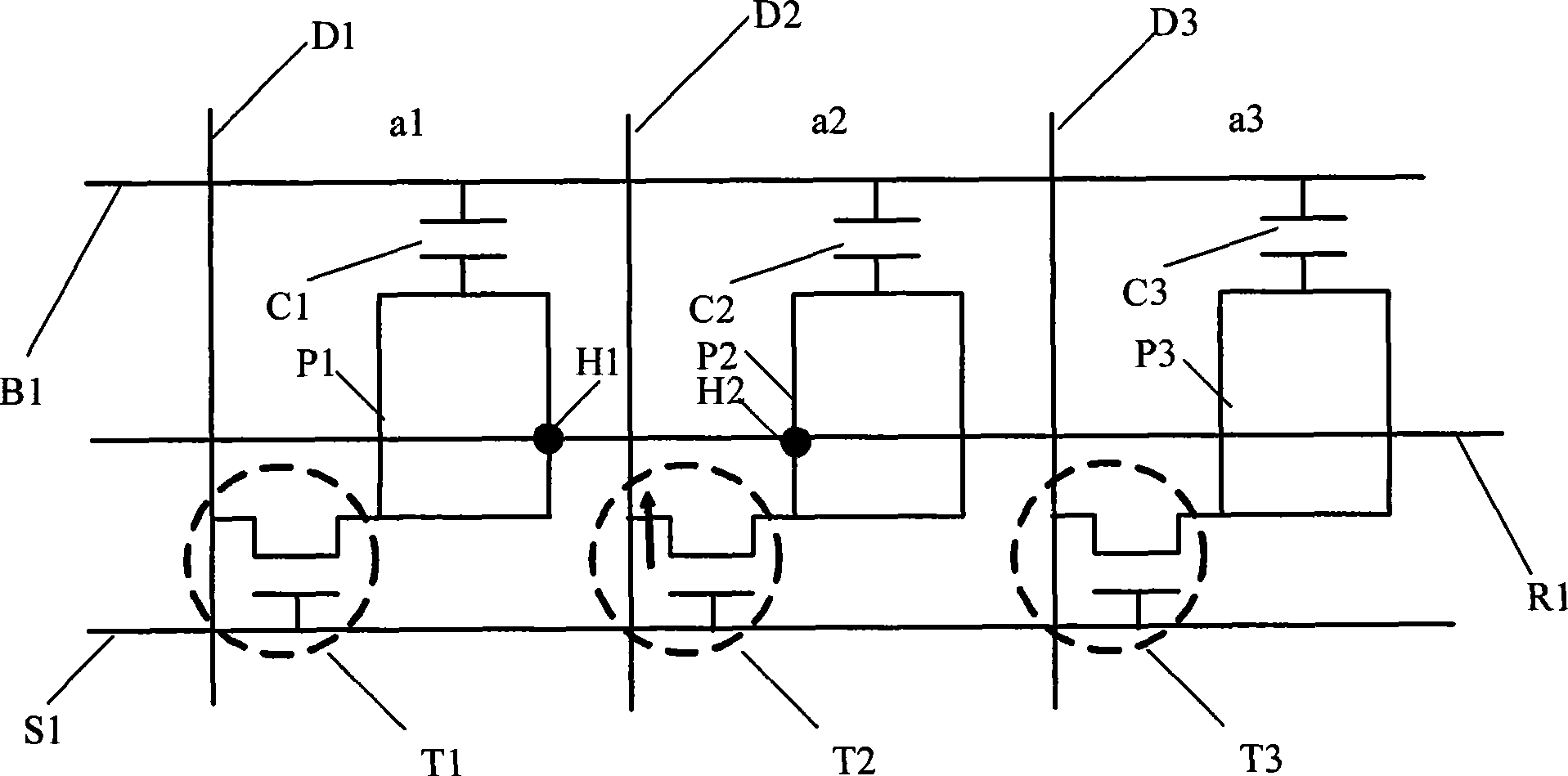

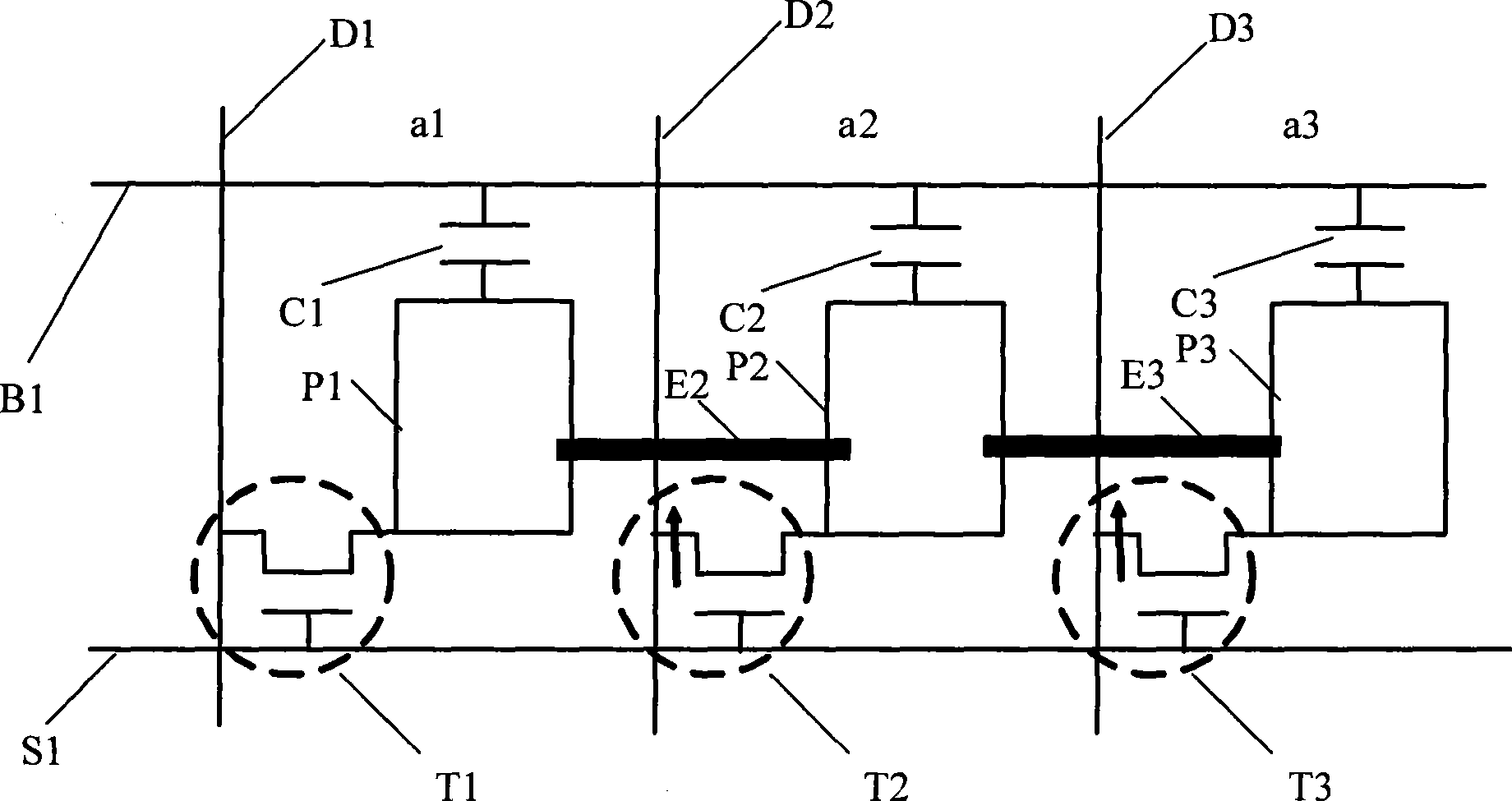

[0014] The point defect repairing method of the liquid crystal display device of the present invention will be further described in detail below with reference to the accompanying drawings.

[0015] figure 1 It is a schematic diagram of the first embodiment of the point defect repairing method of the present invention. exist figure 1 Among them, the display area of the liquid crystal panel is composed of many display units, each display unit is composed of three sub-pixels a1, a2, a3 of red, green, and blue, and each sub-pixel is composed of pixel electrodes P1, P2, P3, storage capacitor C1 , C2, C3, transistors T1, T2, T3, scan line S1 connected to the gate of the transistor, and data lines D1, D2, D3 connected to the source of the transistor. The storage capacitors C1, C2, C3 are respectively connected to the common electrode line B1 and the pixel electrodes P1, P2, P3.

[0016] In the later stage of the liquid crystal panel array project, that is, after the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com