Fixed side-installed vacuum circuit breaker

A technology of vacuum circuit breaker and fixed side, applied in the direction of high-voltage air circuit breaker, circuit, electrical components, etc., can solve the problems of difficult installation and maintenance, complex manufacturing process, poor reliability, etc., and achieve simplified manufacturing process, compact structure, The effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

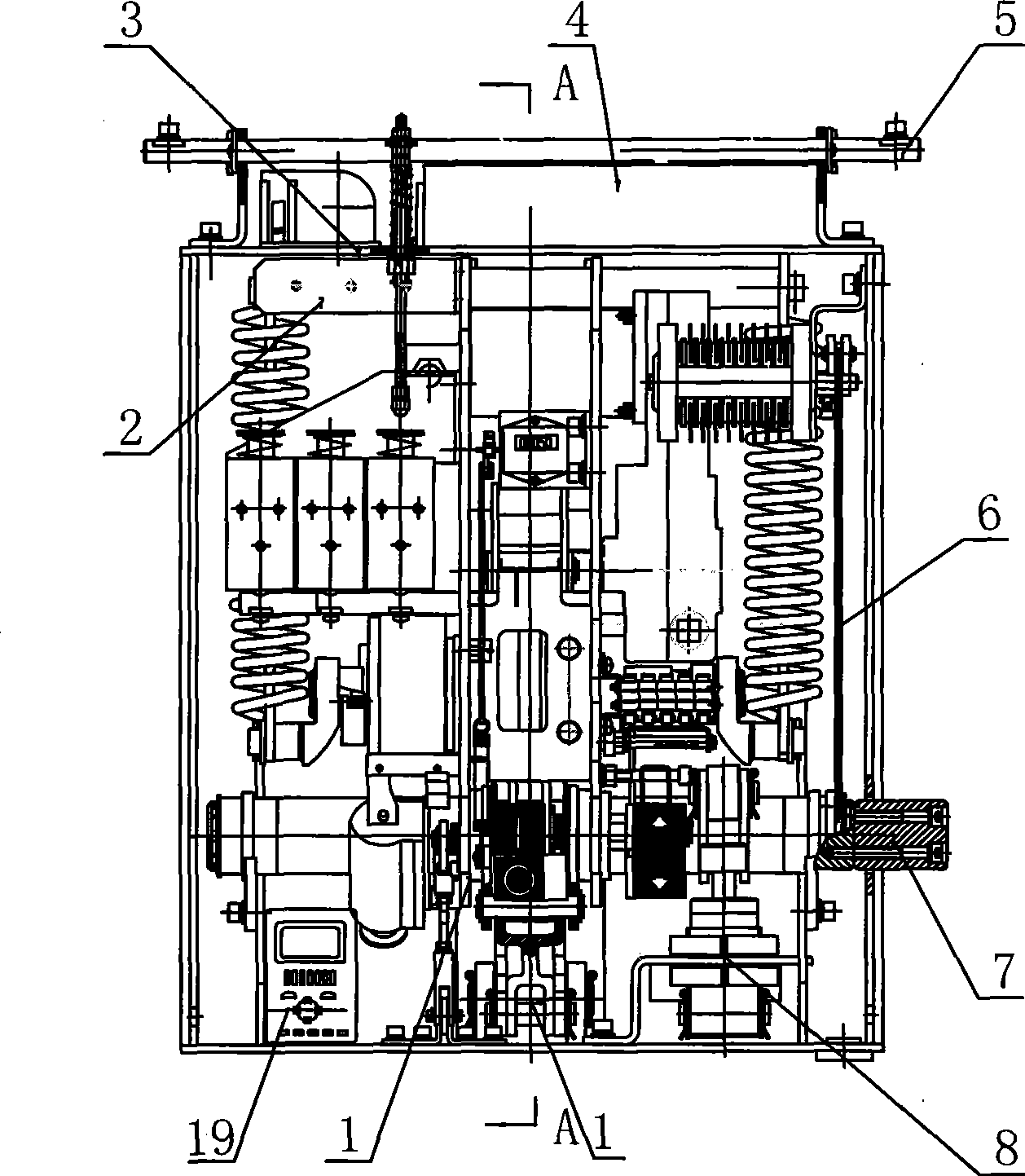

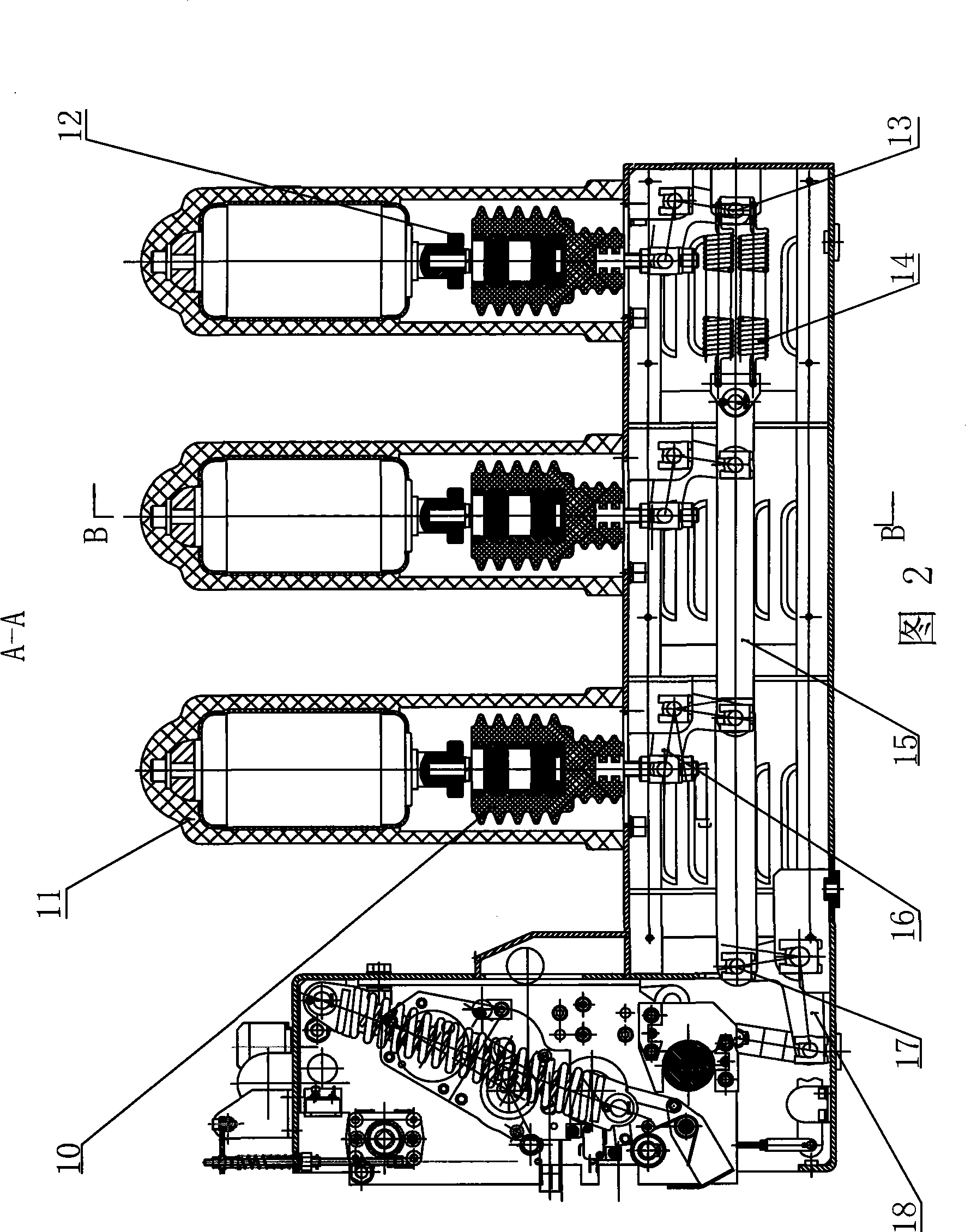

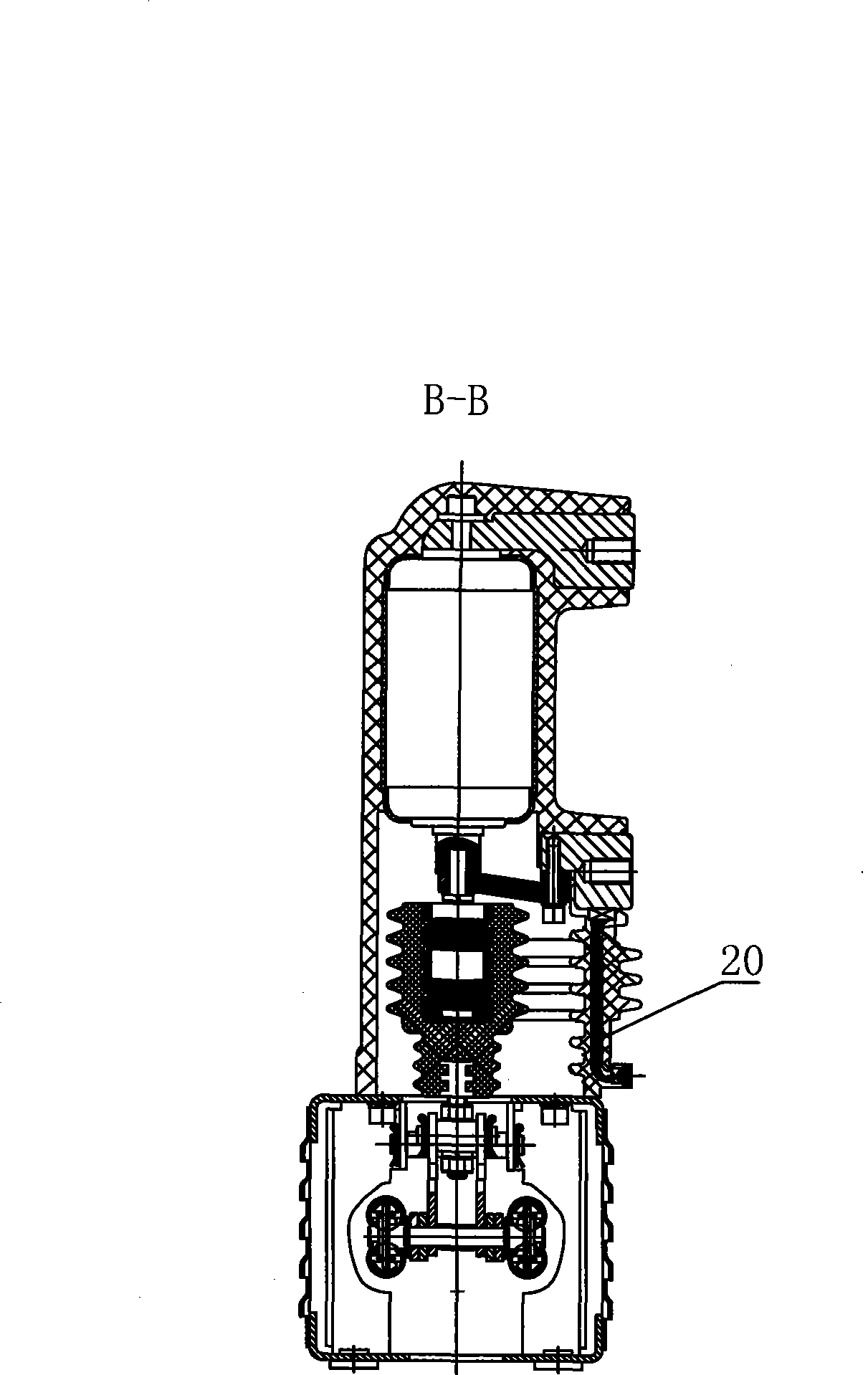

[0017] according to Figure 1~3 The specific structure of the present invention will be described in detail. The fixed side-mounted vacuum circuit breaker includes a main box 3, a modular controller 2 assembled in the main box 3, a terminal block 4, an opening interlock mechanism 5, an auxiliary switch group 6, an output shaft interlock shaft 7, an oil pressure Buffer 8, spring operating mechanism, output four-linkage 18, vacuum interrupter and its contact pressure spring, operating insulator 10 and other parts. A key part of the device, the spring operating mechanism, adopts the inventor's previous patent "miniature spring operating mechanism 1 for vacuum circuit breaker (patent announcement number is CN100380553C)", which is assembled in the main box 3 after modularization. Inside the front-end box; another key component, the vacuum interrupter, adopts a miniaturized one-time sealing and exhausting ceramic interrupter. The vacuum interrupter and the main conductive circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com