Single-screen cover multipurpose vibrating screen

A technology of vibrating sieve and sieve surface, which is applied in the direction of filter screen, solid separation, grille, etc., to achieve the effect of easy cleaning, convenient use and less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

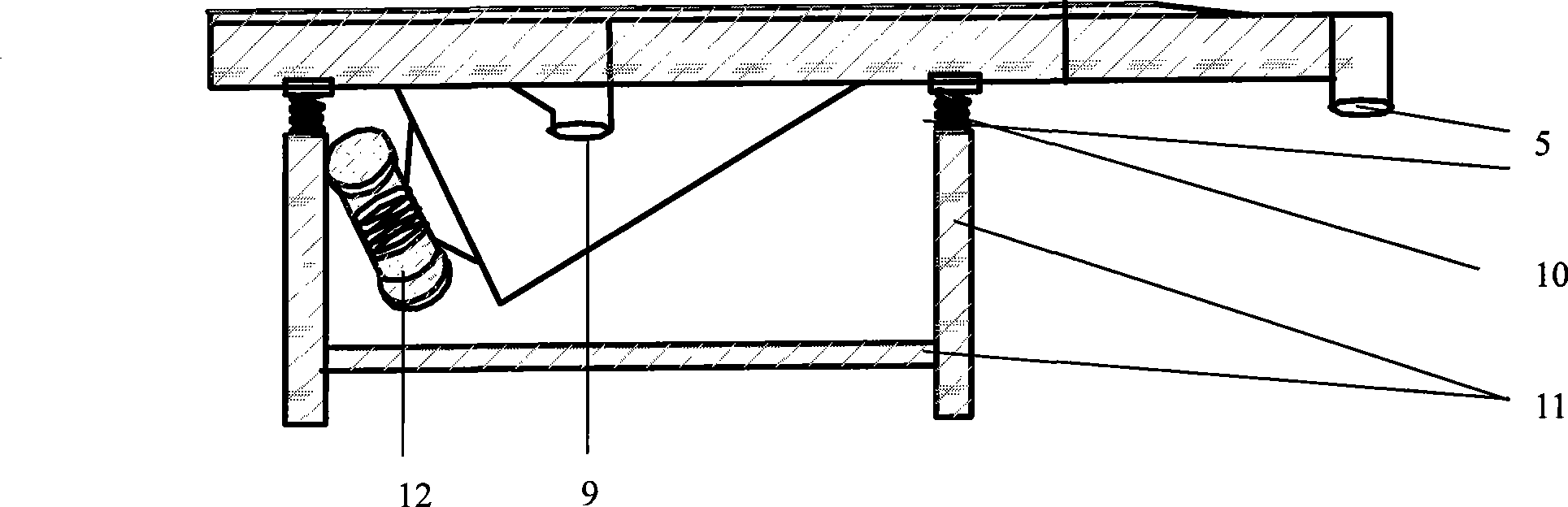

[0023] like Figure 1-4 The shown multi-purpose vibrating screen with a single screen surface is a creative improvement to the existing multi-layer combined vibrating screening device. It includes a vibrating motor 12, a sieve body support frame 11, a vibrating spring 10 and a screening assembly A arranged on the vibrating screen bracket, and is characterized in that:

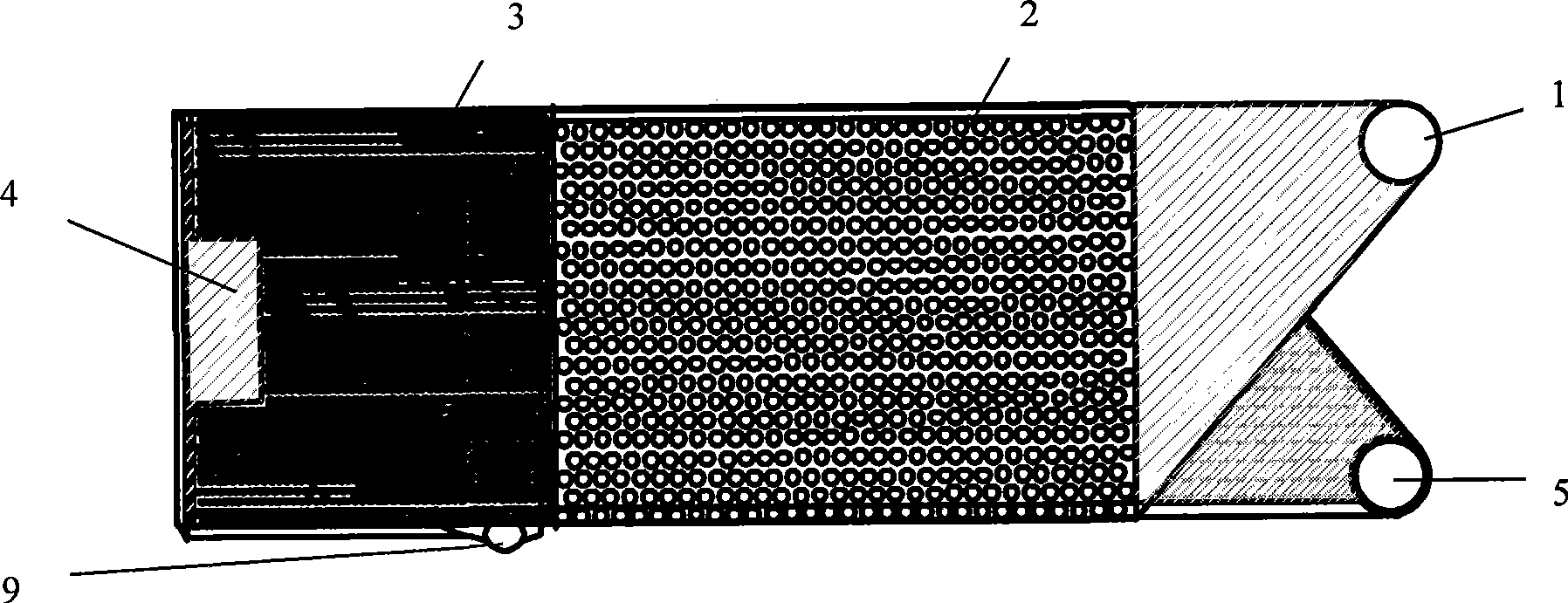

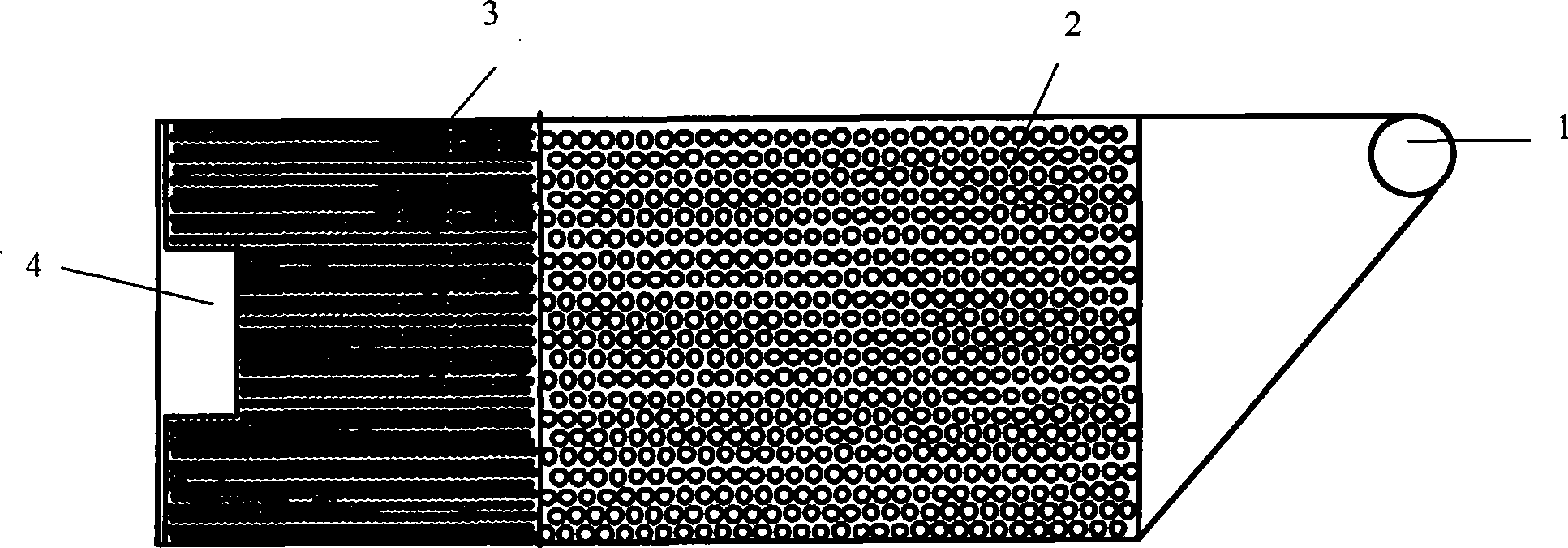

[0024] A. The screening assembly A is composed of an upper sieve plate A-1 and a lower separation disc A-2;

[0025] B. The upper sieve plate A-1 is a polygonal frame plate, on which two pieces of powder sieve mesh 3 with separated powder materials and standard mesh 2 for qualified products to sieve are arranged on the frame surface , and at the same time, an equalizing plate 4 and a non-genuine outlet 1 are provided on the upper sieve plate A-1;

[0026] C. The disc panel of the lower separation disc A-2 is provided with a separation plate 7, which divides the separation disc surface into corresponding powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com