Method for high-efficiency allowance-removing numerical control machining for groove-cavity structured part with corner

A processing method and cavity technology, applied in the field of high-efficiency CNC milling, can solve the problems of affecting the efficiency of rough machining of parts, affecting the finishing machining, and reducing the rigidity of tools, so as to achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] After analyzing the structural features of many products, the processing method of the present invention has typical application effects on the following two parts structures.

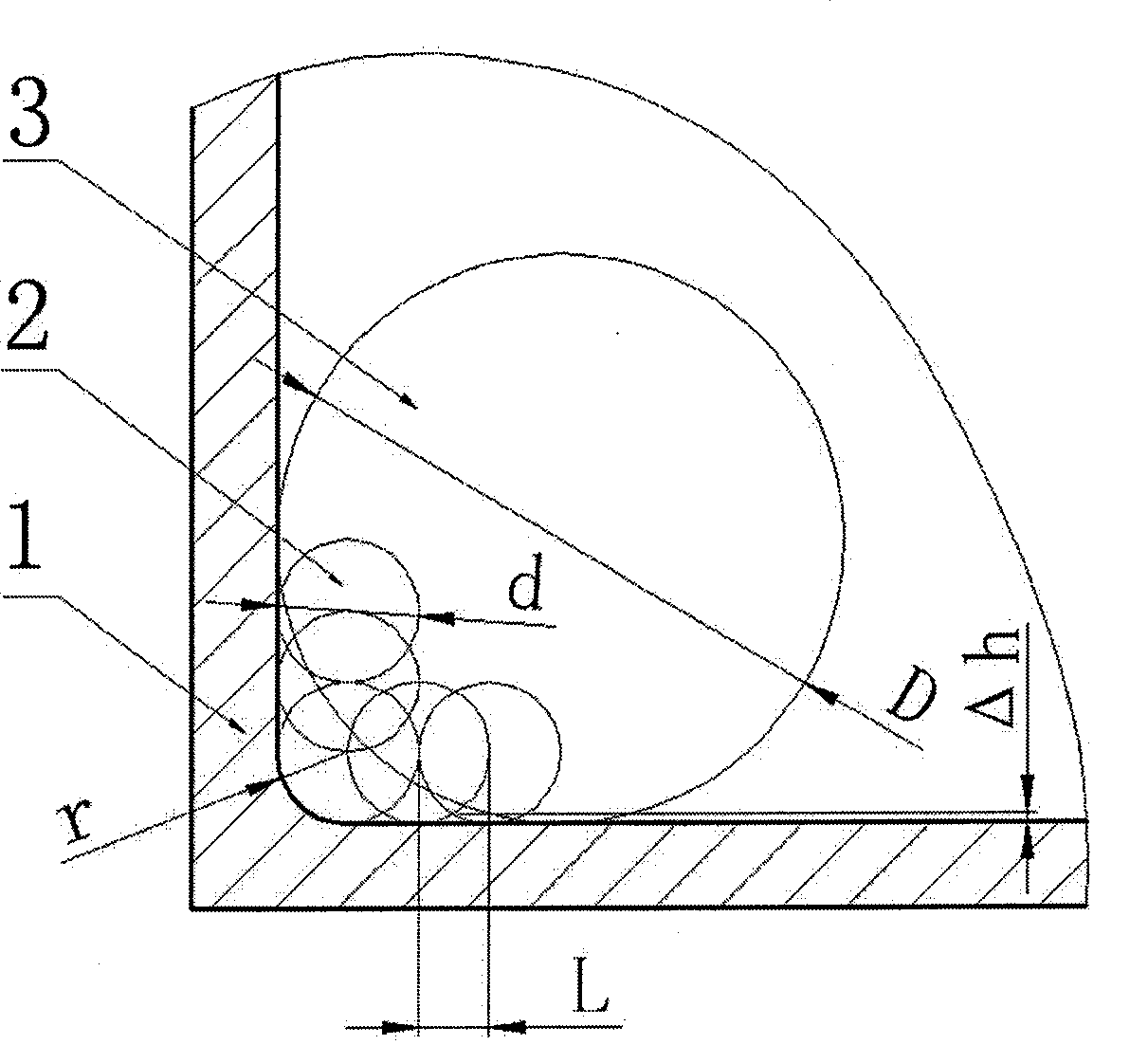

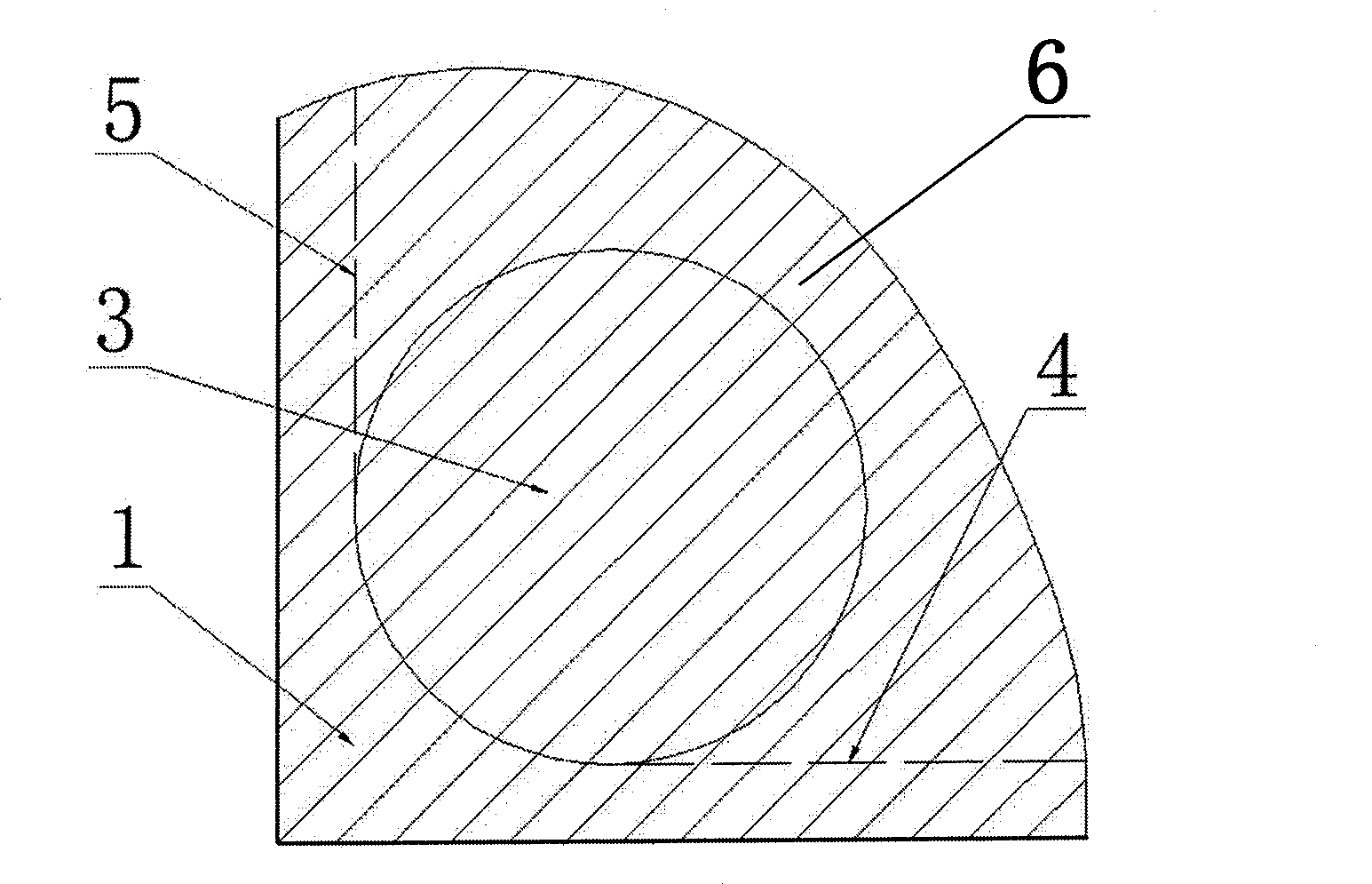

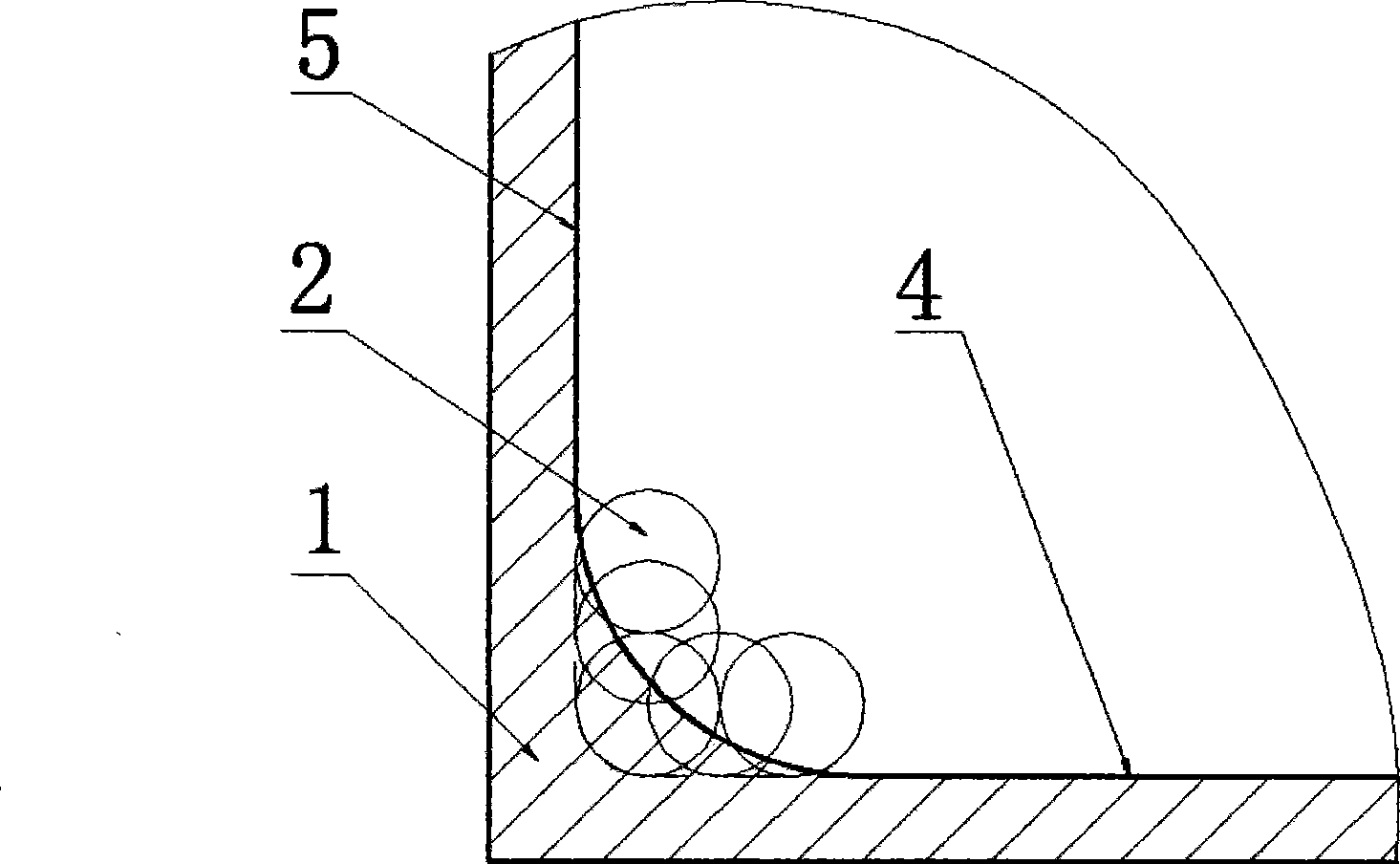

[0019] The first type of typical deep cavity structure: relative to the size of the corner, the depth of the cavity is large. When the structure is selected and processed according to the traditional processing method, the length-to-diameter ratio of the tool reaches or exceeds 3 to 4, which is far greater than the general processing state. At this time, the rigidity of the tool drops sharply, resulting in a greatly reduced processing efficiency. After adopting the processing method of the present invention, the groove cavity is milled with a large-diameter tool (the radius of the tool is 4 times the corner radius), which can greatly reduce the length-to-diameter ratio of the tool and realize efficient and fast cutting; use a small-diameter tool for corner plunge milling, The plunge milling cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com