Separation method apparatus for pill-sand mixture after cast surface treatment

A surface treatment and separation method technology, which is applied in the direction of used abrasive treatment devices, abrasives, metal processing equipment, etc., can solve problems such as low efficiency, reduced separation quality, and inclusion of metal impurities, so as to achieve safe and reliable use and improve Protect the environment and separate the effects of strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

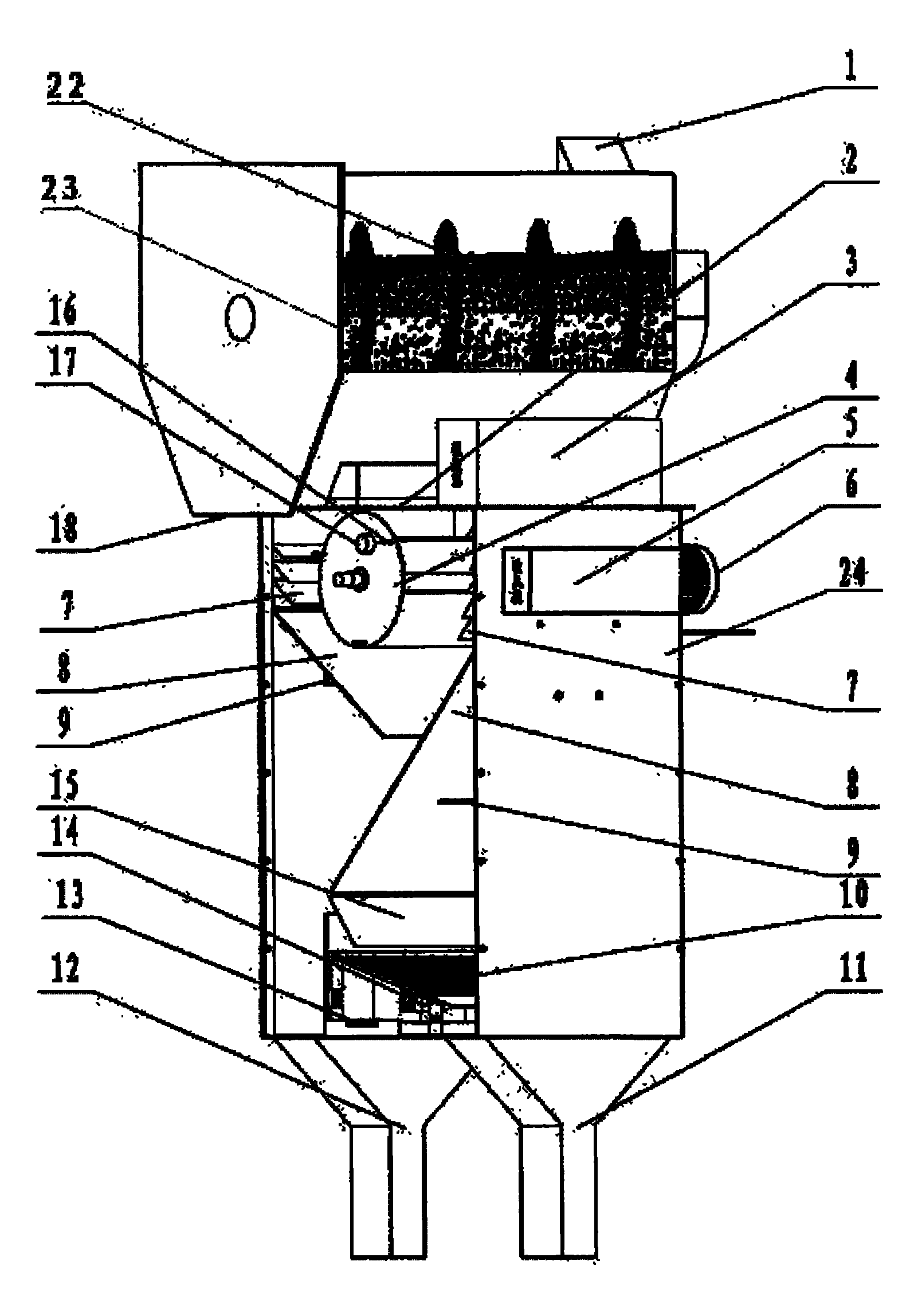

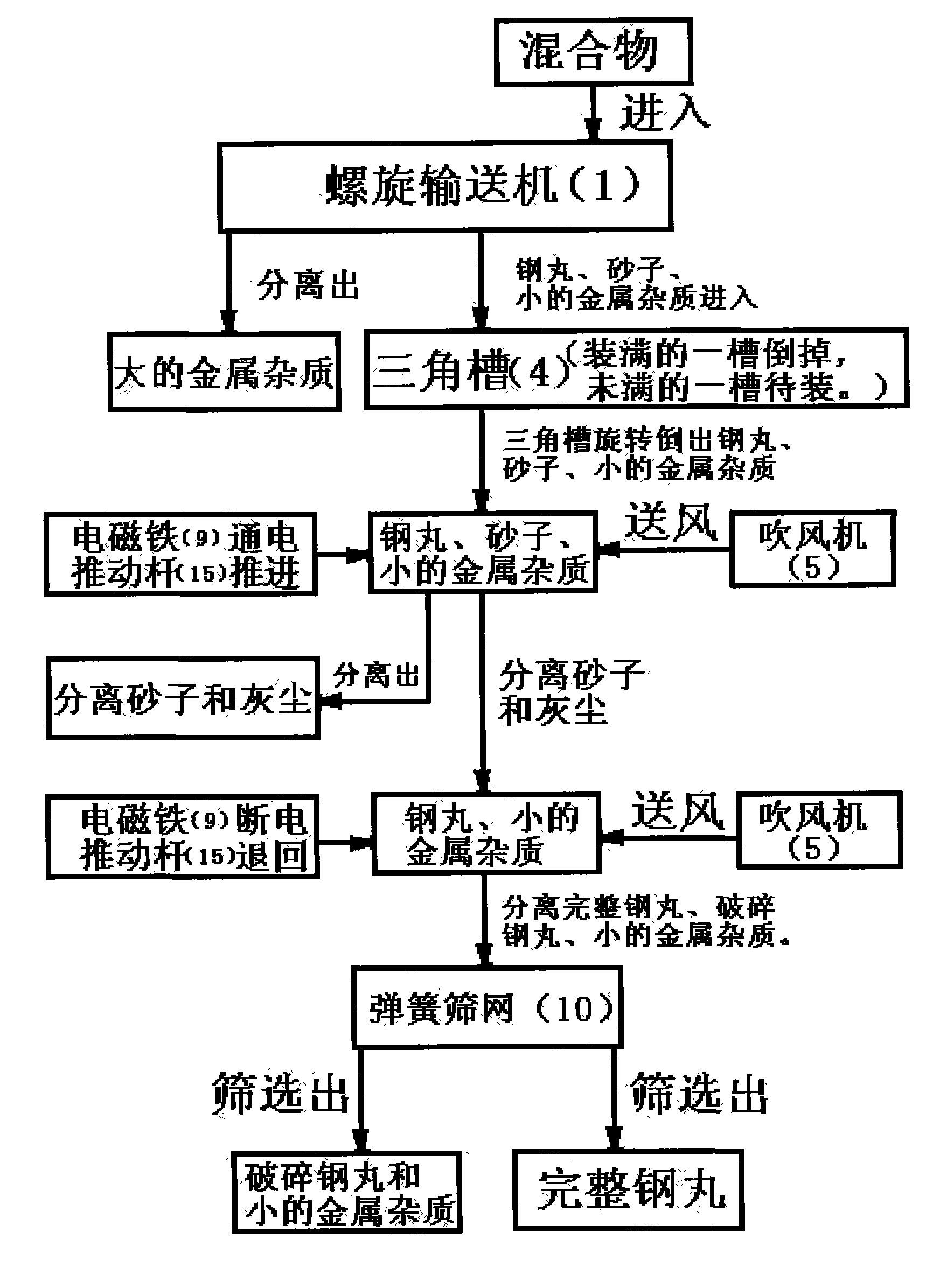

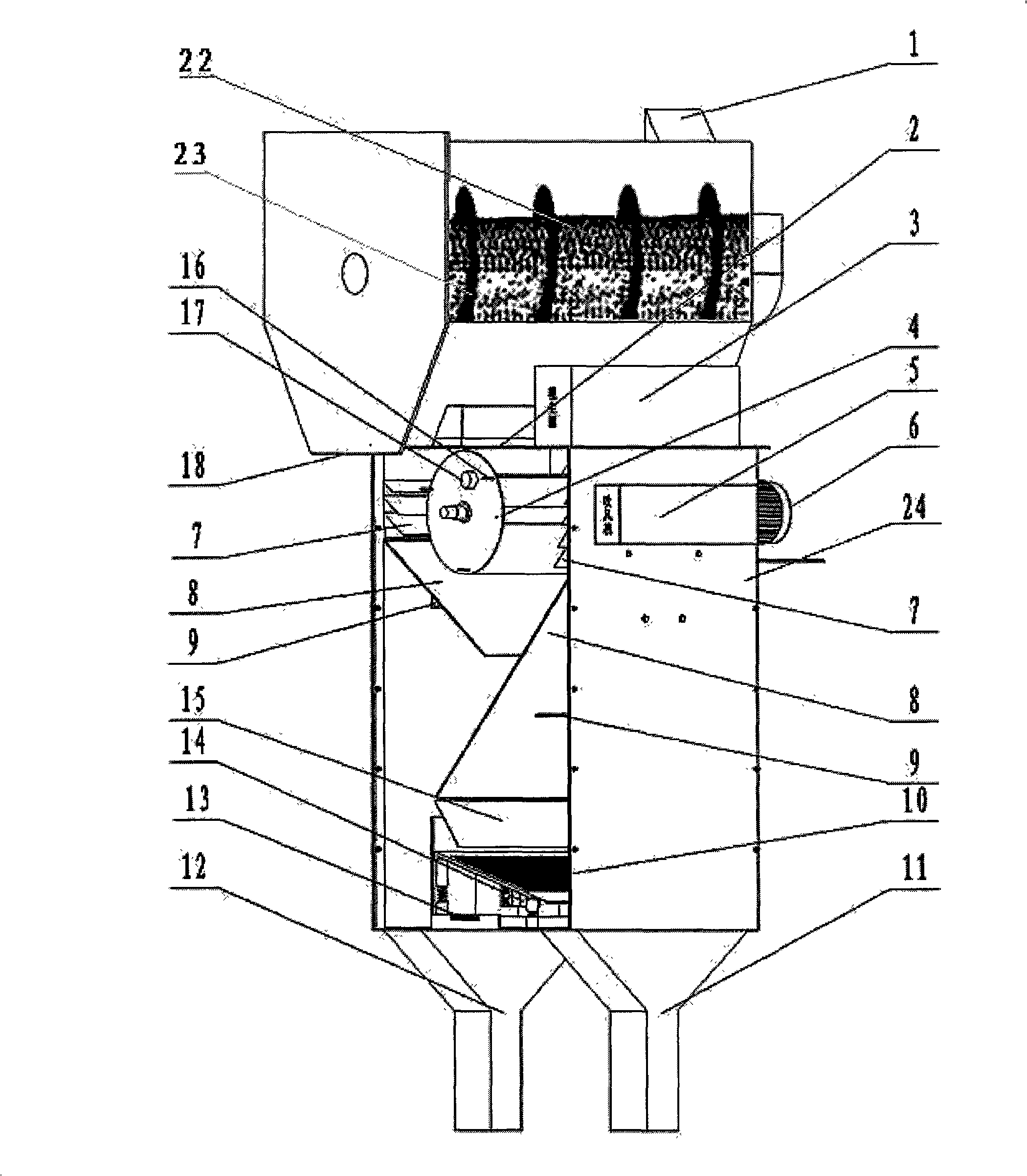

[0022] The embodiments of the present invention are described as follows with reference to the drawings:

[0023] The structural drawings of a preferred embodiment of the present invention are detailed as follows: as shown in the schematic diagram of Fig. 1, when the mixture enters the screw conveyor, large metal impurities are screened out by the screw conveyor drum, while steel shot, sand and small metal The impurities are sent to the triangular groove. Regular rotation of the triangular slot, pour the full mixture on the separation plate. While the electromagnet is energized to adsorb the steel shot and small metal impurities, the blower separates the sand and dust contained in the steel shot and small metal impurities. When the electromagnet is powered off, steel shots and small metal impurities are intercepted by the push rod and enter the vibrating screen with spring. The work of the vibrating screen separates it into complete steel shots, broken steel shots and small met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com