Five-shaft heavy-duty car steering system

A technology for heavy-duty vehicles and steering systems, which is applied to steering mechanisms, steering rods, vehicle components, etc., and can solve the problems of poor steering flexibility and reliability, large force on transmission parts, and high material consumption, and achieve flexibility and reliability. Guaranteed, overall light weight, flexible steering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

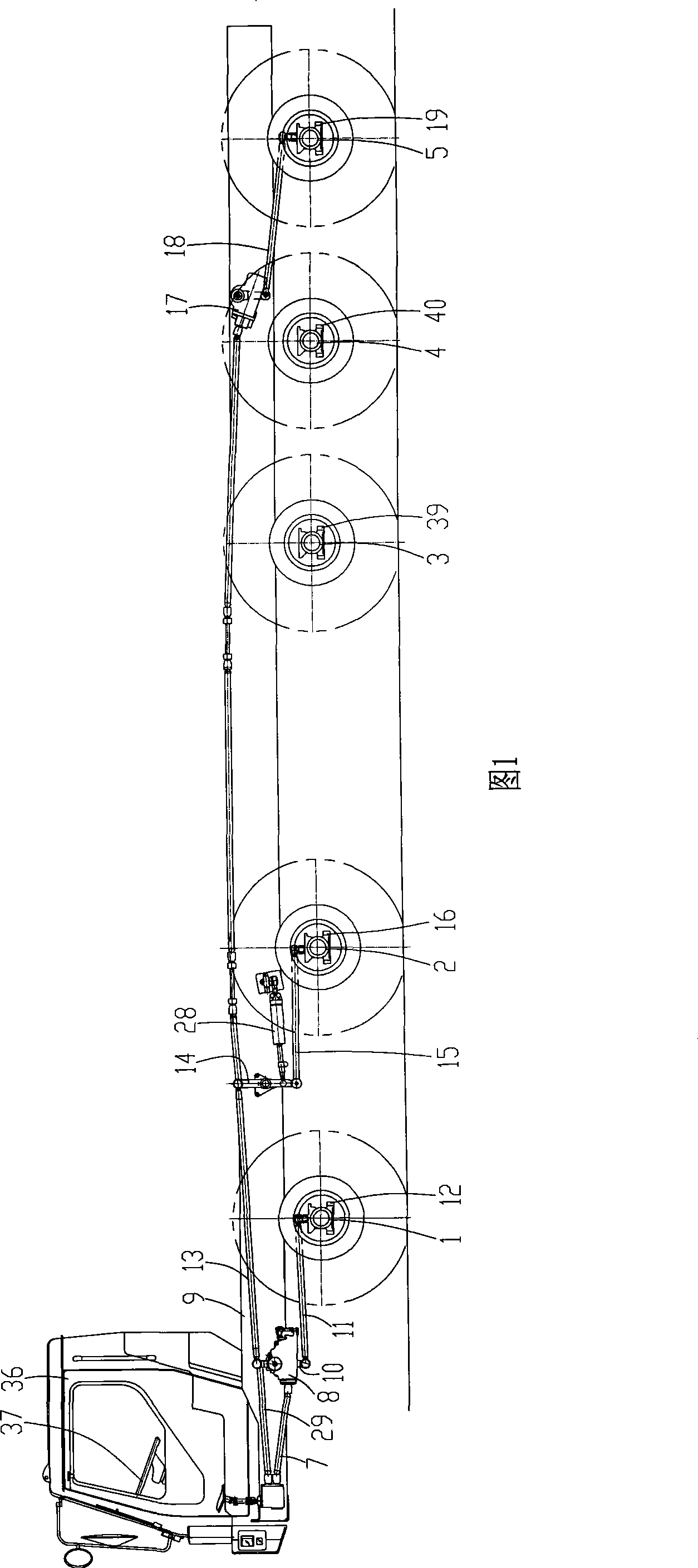

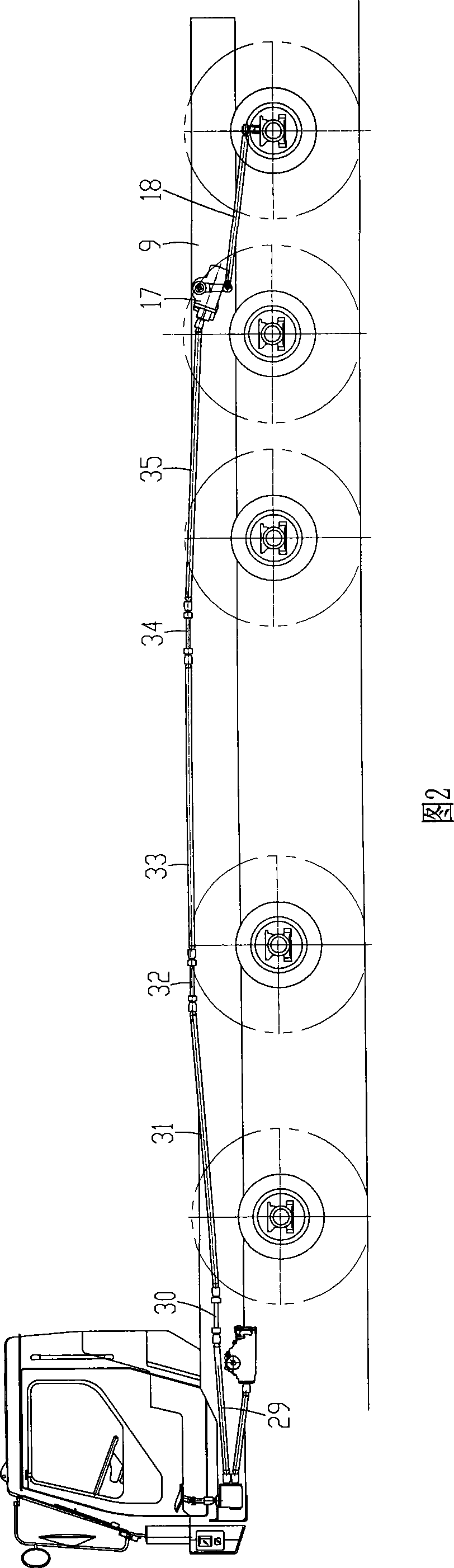

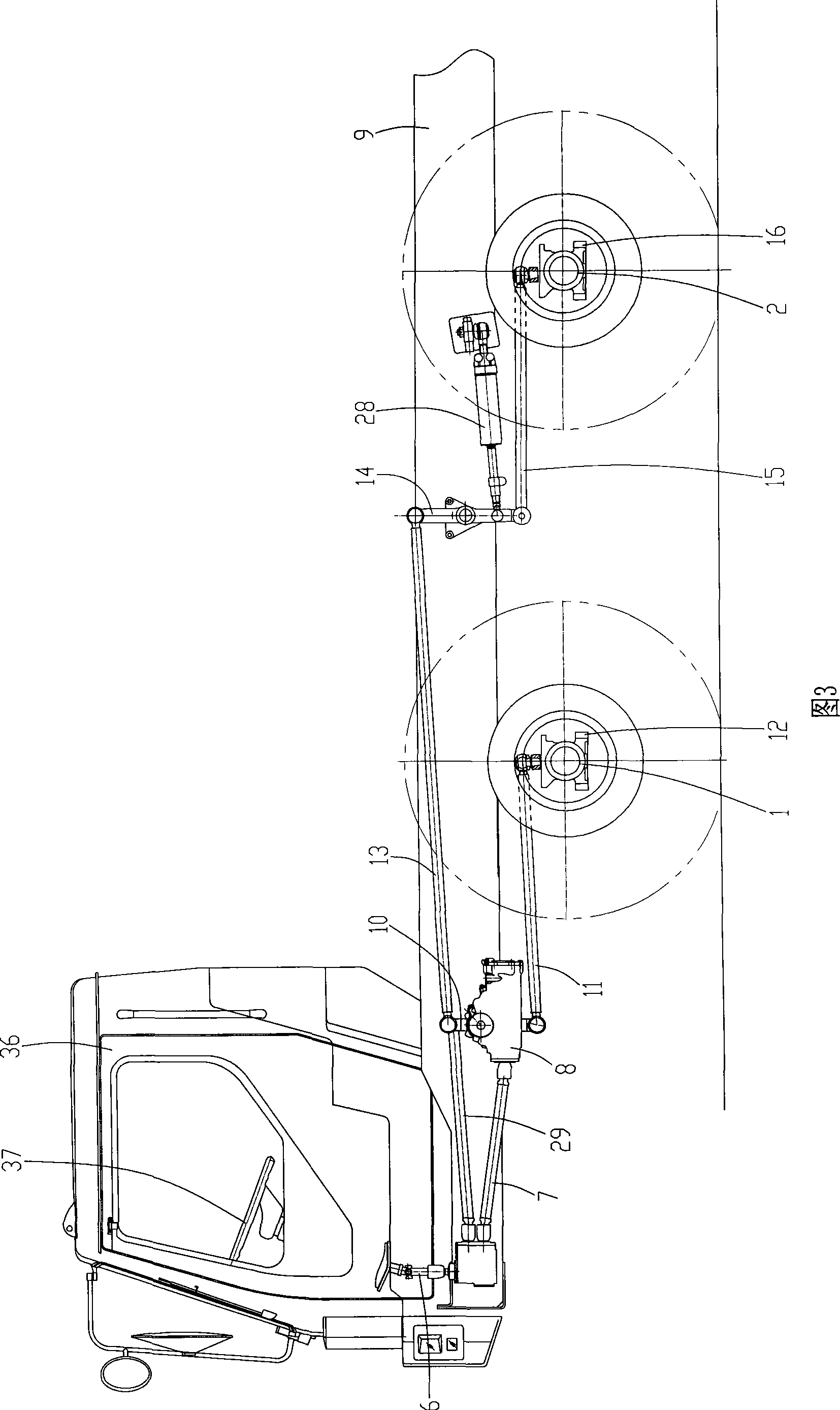

[0034] As shown in Fig. 1 and Fig. 2, five axles 1, 2, 3, 4, 5 are arranged from front to back under the chassis longitudinal beam 9, and each axle is set in the axle tube, and the two ends of the axle are connected respectively from the The two ends of axle tube stretch out, and stretching out part installs steering wheel (shown in double-dot dashed line among Fig. 1,2,3). Wheel hubs are fixed on each of the shaft tubes, and a steering arm is provided on the wheel hubs, wherein the first wheel hub 12 corresponds to the first wheel shaft 1, the second wheel hub 16 corresponds to the second wheel shaft 2, and the third wheel hub 39 corresponds to the third wheel shaft 3. The four hubs 40 correspond to the fourth axle 4 , and the fifth hub 19 corresponds to the fifth axle 5 . The structure of the wheel hub, the steering arm, and the installation method of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com