Adsorption column top cover integration of oxygen generator

A technology of adsorption tower and oxygen generator, which is applied in inorganic chemistry, oxygen preparation, oxygen/ozone/oxide/hydroxide, etc. It can solve the problems of easy displacement, difficult assembly, complex design, etc., and improve the sealing performance and reliability, facilitates miniaturization, and simplifies installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

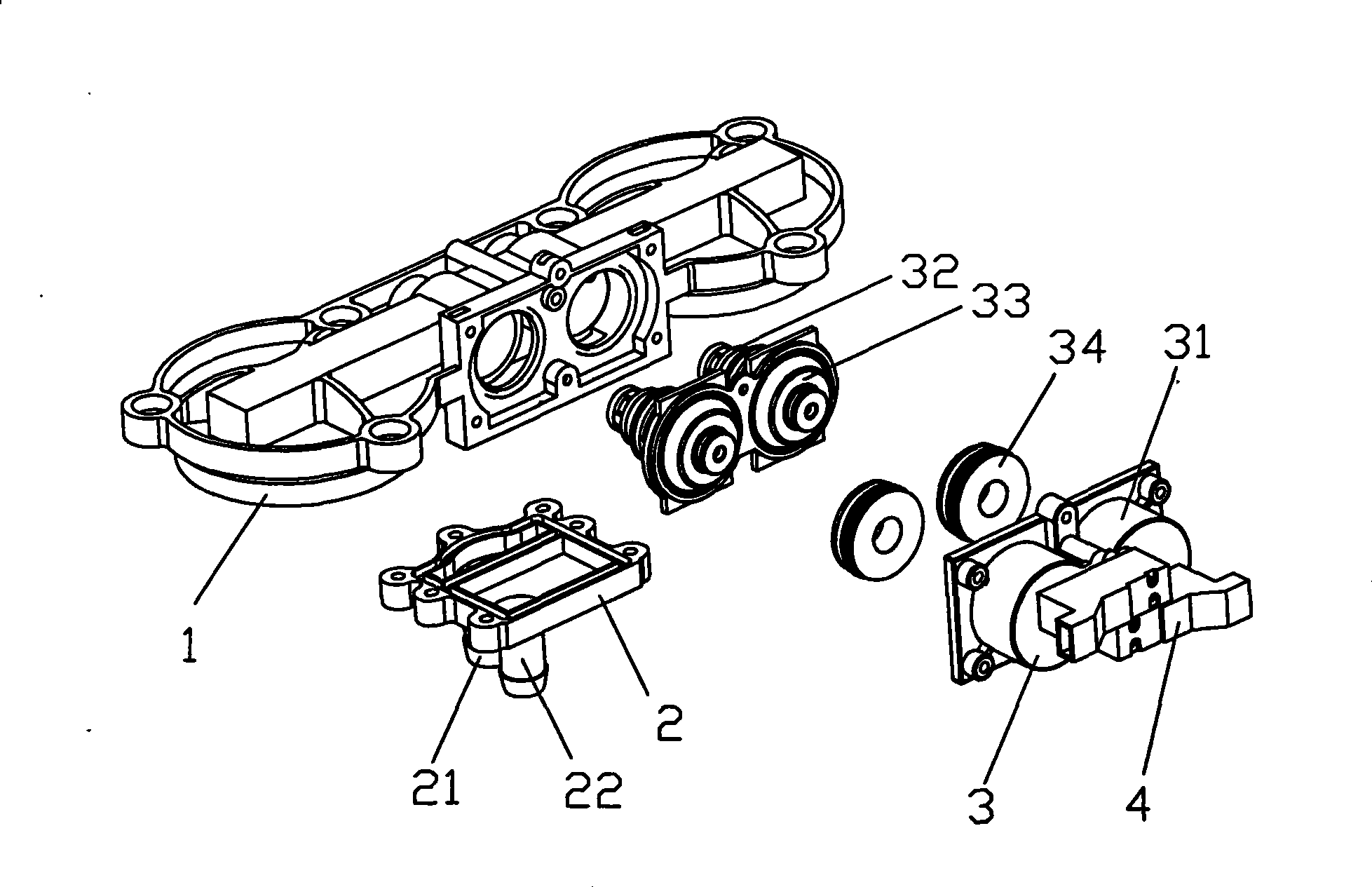

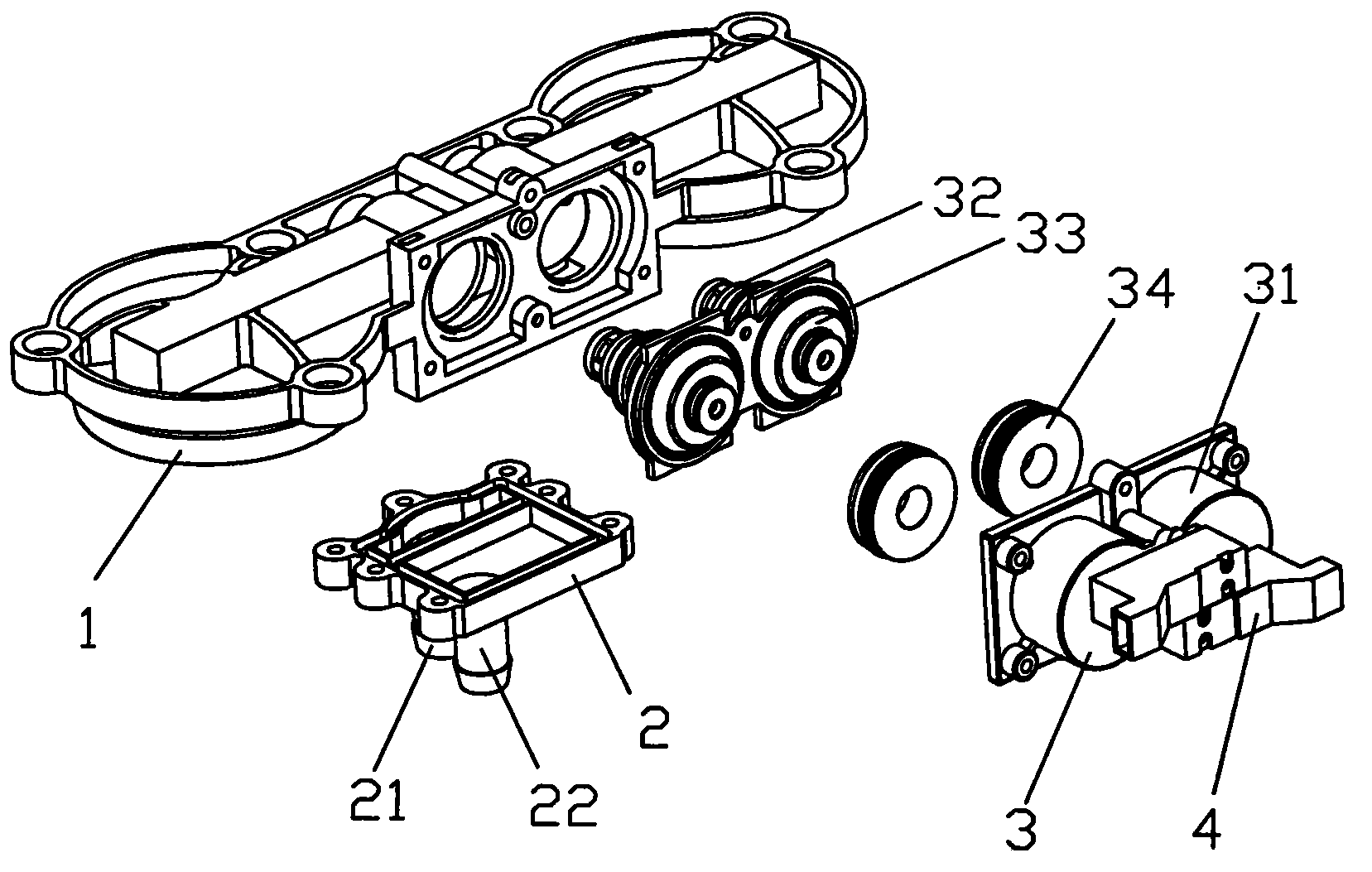

[0010] refer to figure 1 , an adsorption tower cover integration of an oxygen generator, which includes an adsorption tower cover 1, an air passage connecting plate 2 is sealed and installed at the bottom of the adsorption tower cover 1, and a compressed air inlet 21 and an exhaust gas outlet are arranged on the air passage connecting plate 2 Nitrogen port 22, a pneumatic valve 3 is installed on the side of the upper cover 1 of the adsorption tower, and a pilot solenoid valve 4 is arranged on the pneumatic valve 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com