Integral shift method for buildings

A building and overall technology, applied in the direction of building structure, construction, building maintenance, etc., can solve problems such as unsuitable permanent foundations, increased translational instability, and reduced building safety, so as to facilitate construction management and reduce in-transit Risk, the effect of short translation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

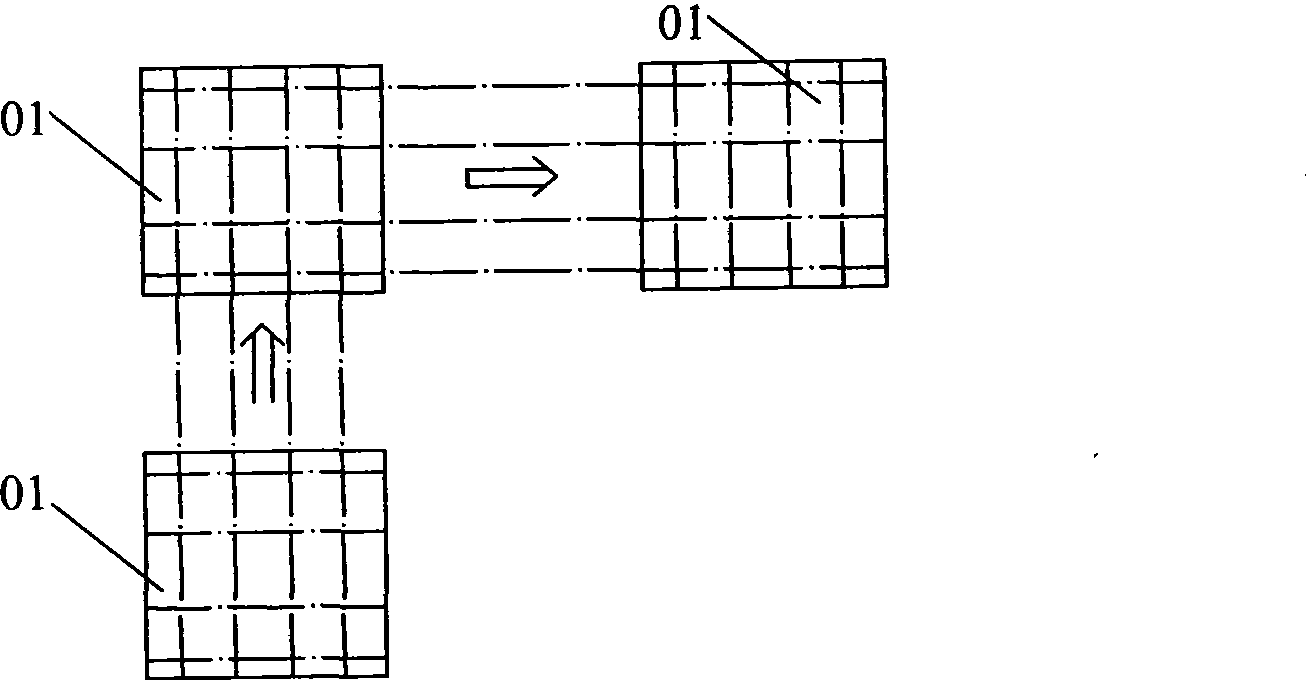

[0073] The overall shifting method of the building usually includes translation and jacking of the building.

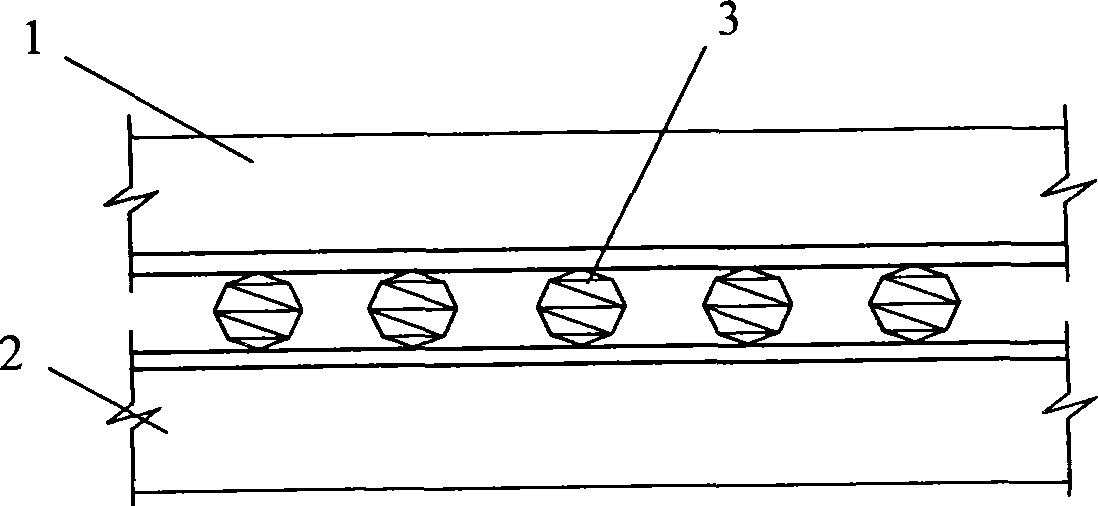

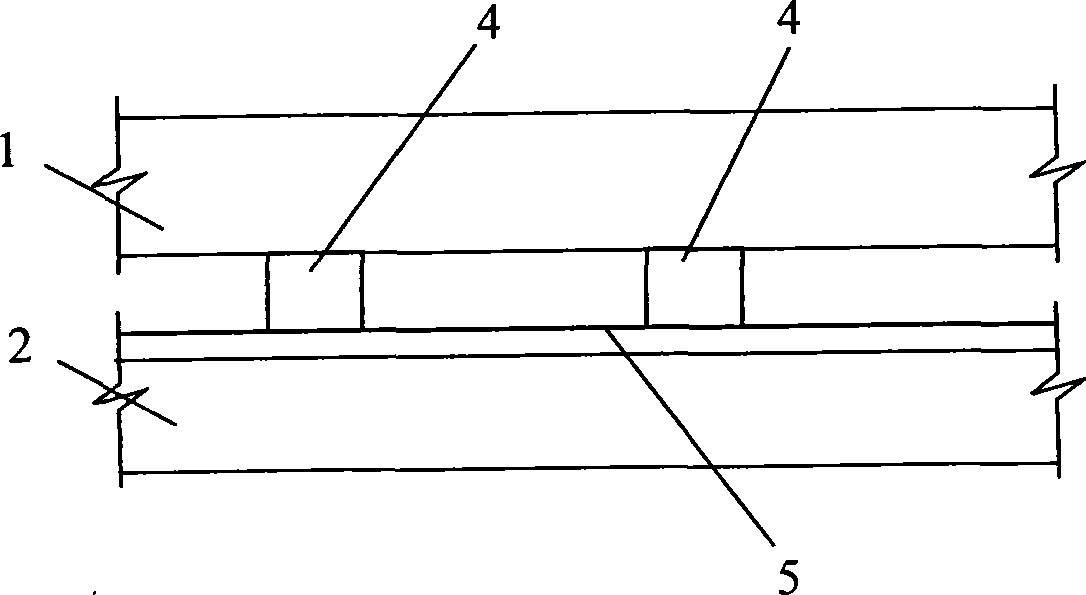

[0074] Wherein, in the overall building displacement method described in the present invention, the translation of the building is to install a sufficient number of hydraulic jacks between the upper sliding beam supporting the building and the lower sliding beam as a slideway, and make the building move along with the building. The hydraulic jack slides on the slideway. During the sliding process, the building is kept stable by controlling the hydraulic pressure of the hydraulic jack at the corresponding position according to the flatness of the slideway surface.

[0075] Specifically, as Figure 6 As shown, a sufficient number of hydraulic jacks 7 are installed between the upper sliding beam 1 and the lower sliding beam 2, and the hydraulic jacks 7 are used as sliding feet, that is, the entire building is placed on several jacks, and the loads designed at each point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com