Refrigerant distributor used for air conditioner heat-exchanger

A refrigerant distributor and heat exchanger technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of not being able to ensure the uniformity of the gas-liquid two-phase, affecting the mute effect of the air conditioner, and reducing the gas-liquid two-phase equalization, Achieve the effect of avoiding refrigerant pulsation and impact sound, avoiding capillary blockage, and reducing separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

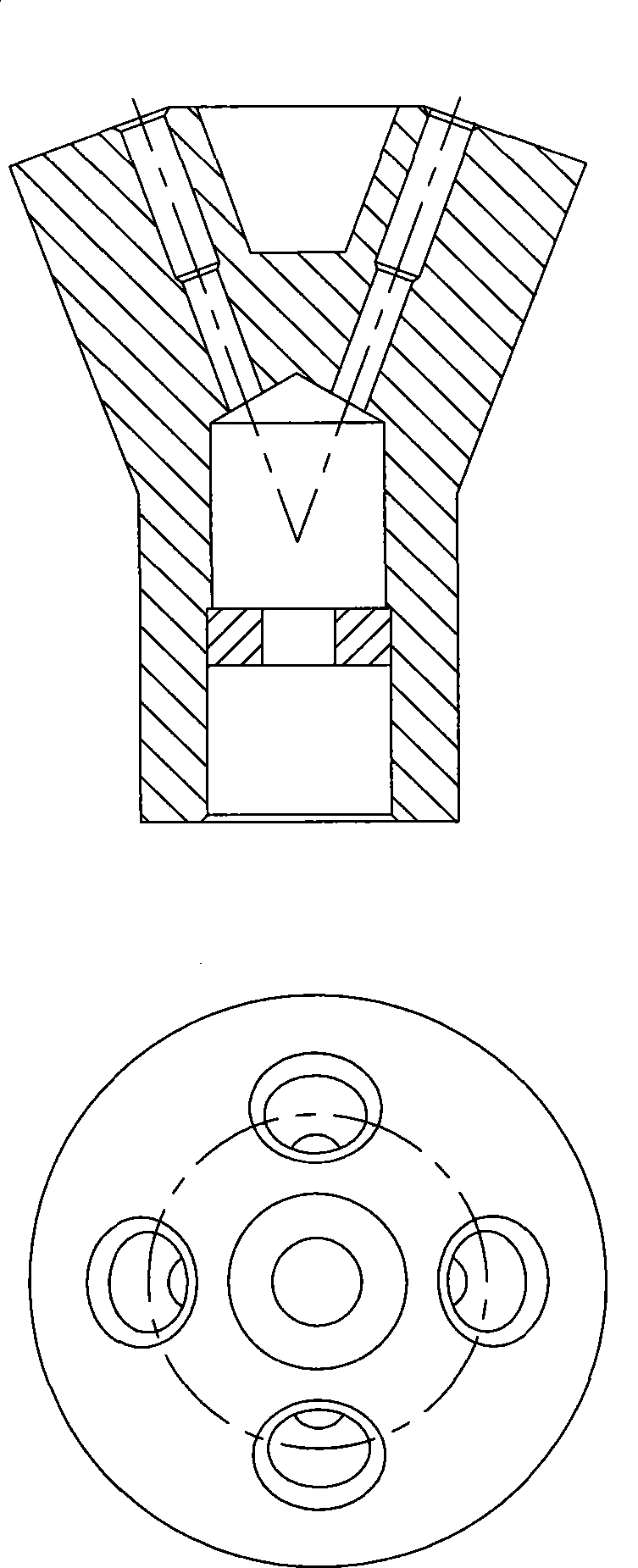

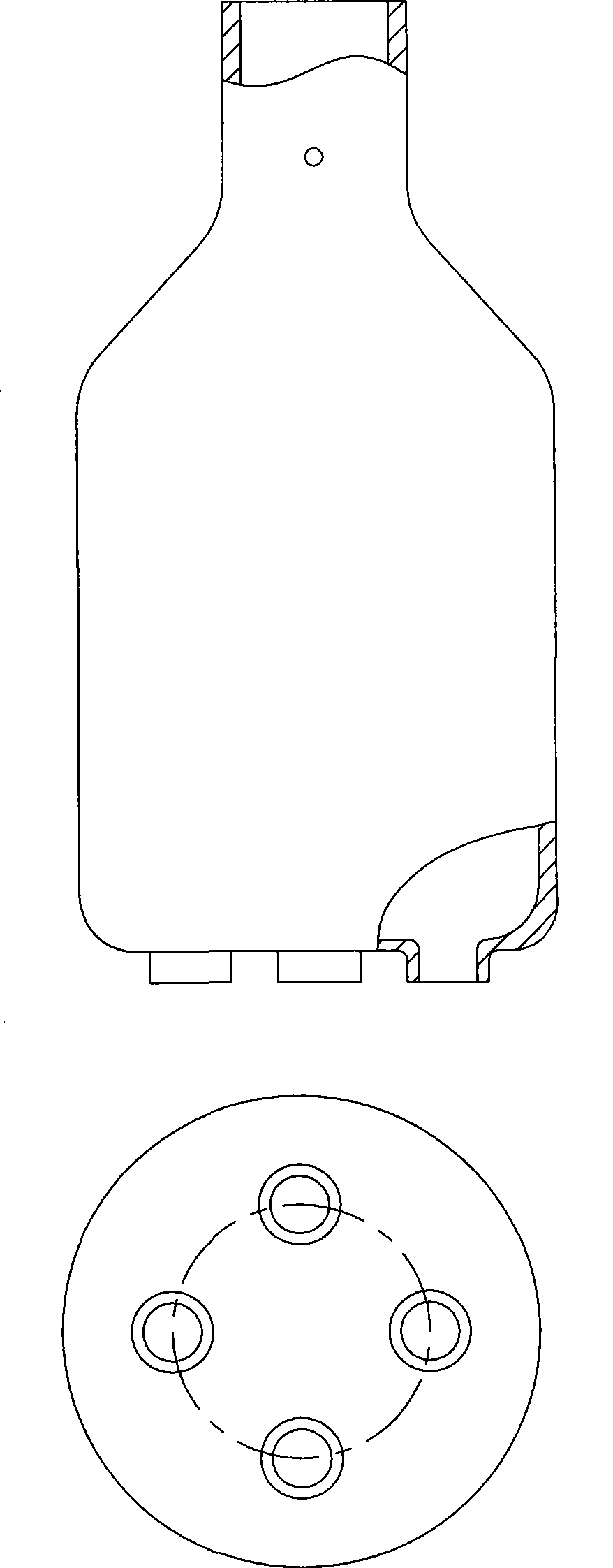

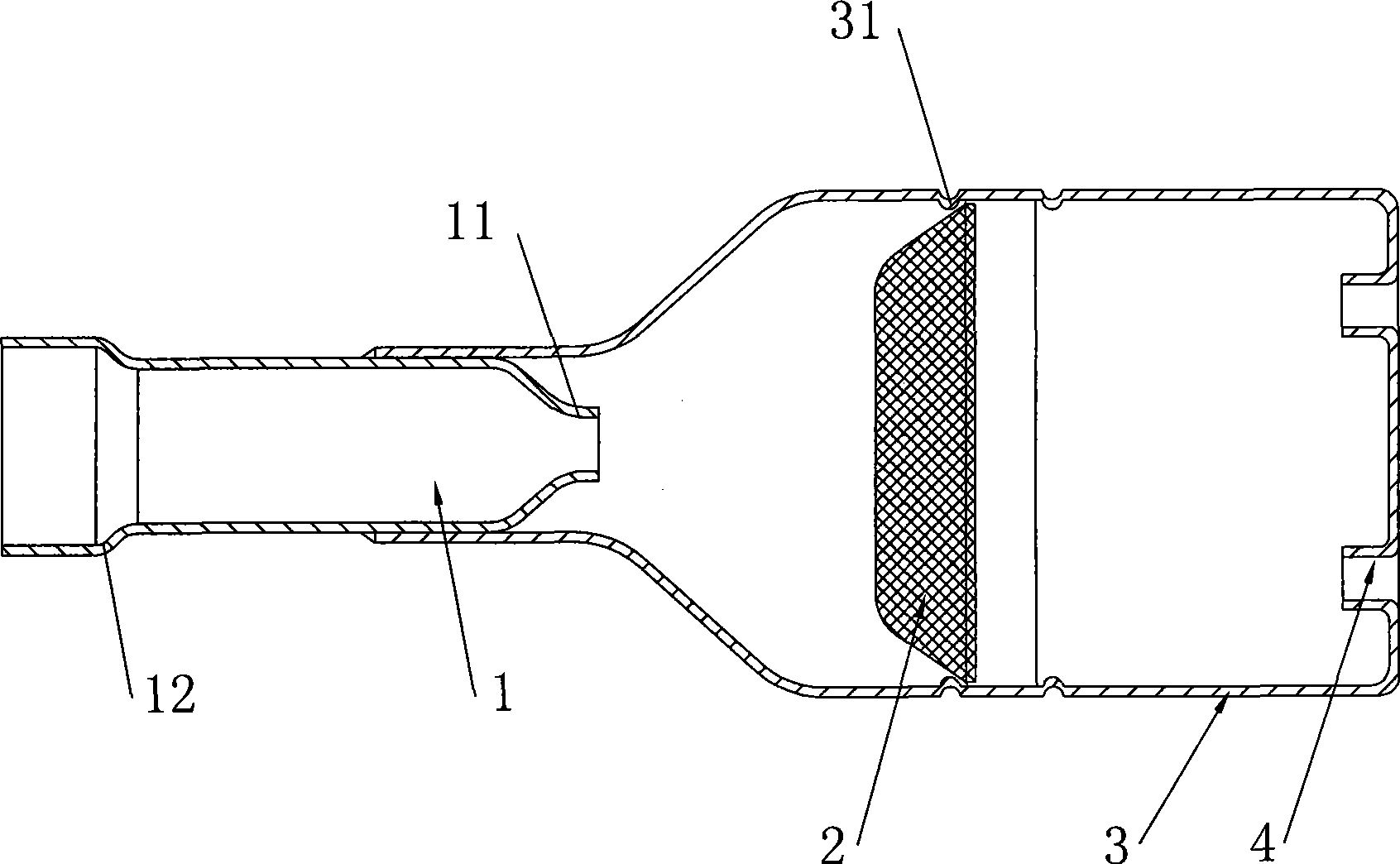

[0015] Such as image 3 , 4 As shown, the refrigerant distributor of the present invention for air-conditioning heat exchangers includes a housing 3 and an input pipe 1 welded on its input end. The output end of the housing 3 is provided with a number of distribution holes 4, wherein the input pipe 1. The nozzle 11 extending into the input end of the housing 3 adopts the form of a tapered mouth, and its diameter is smaller than that of the inlet end 12. A filter screen 2 is installed in the cavity of the housing 3. In this embodiment, the above-mentioned filter screen 2 is installed in the middle of the cavity of the housing 3, the bottom of the screen faces the input end, and the straight section of the screen mouth sticks to the inner wall of the housing 3 and is clamped on two annular protrusions. 31 formed in the shallow groove.

[0016] In this embodiment, the housing 3 is in the shape of a wine bottle, and the diameter of the input end is smaller than the diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com