Electrical control method of rheological measurement device

A technology for electrical control and testing devices, applied in measurement devices, flow characteristics, instruments, etc., can solve problems such as difficulty in implementing electrical control methods, and achieve the effect of ensuring real-time performance and utilizing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Specific embodiments of the present invention are described in detail below.

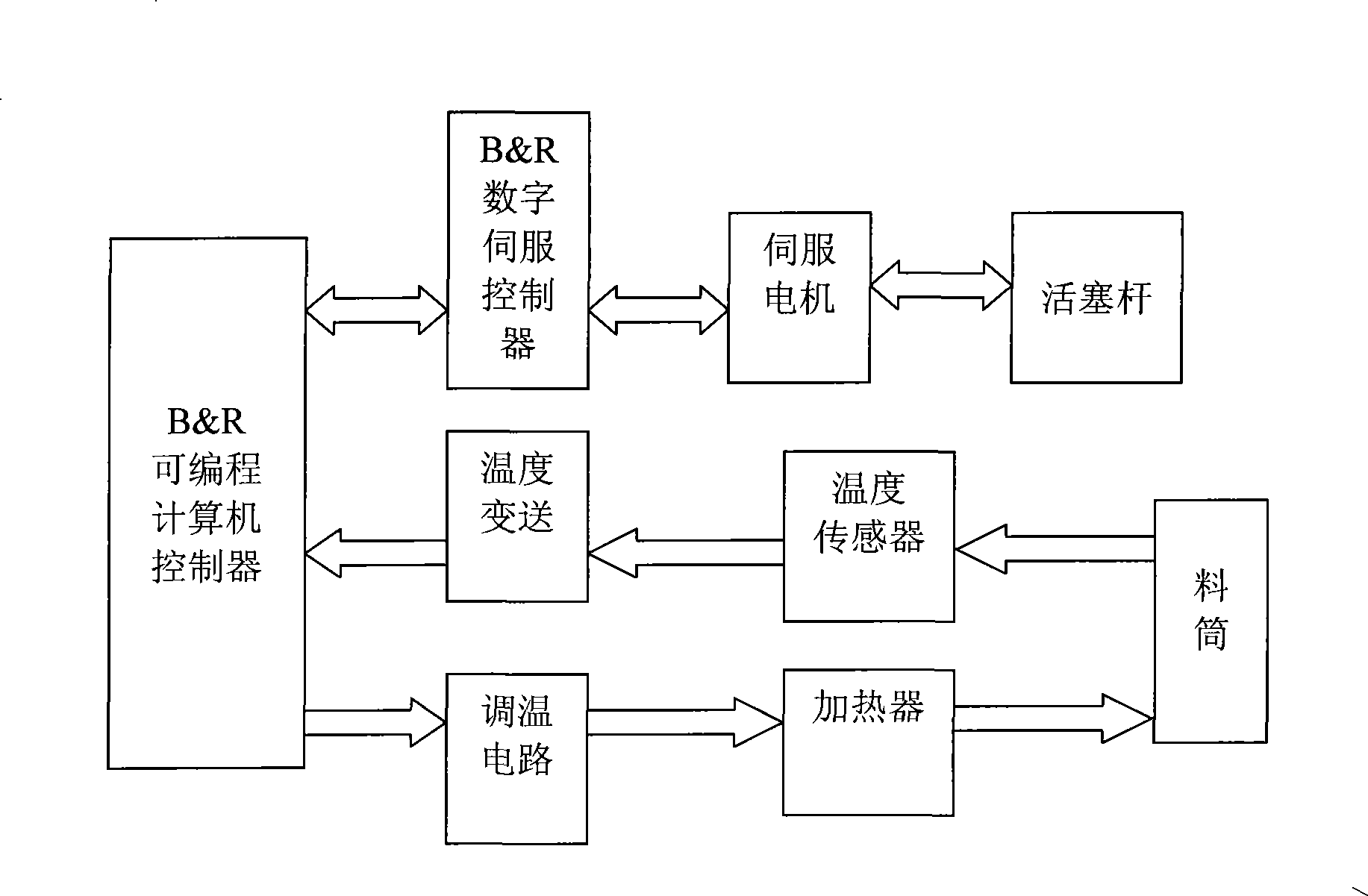

[0008] As shown in the drawings, the present invention adopts the B&R programmable computer controller as the controller; adopts the B&R all-digital intelligent servo system to control the motion speed of the piston rod, and the servo controller and the programmable computer controller are connected by the CAN bus; The control algorithm dynamically configures the speed loop parameters of the servo system at different operating speeds of the piston rod; the precision thermal resistance temperature sensor and the special transmission module are used to detect and convert the temperature of the barrel, and the temperature of the barrel is adjusted through the temperature adjustment circuit. Control; control programs such as intelligent temperature control, parameter configuration of all-digital intelligent servo, and intelligent alarm and protection are defined according to the level of the task ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com