High-power LED packaging and die bonding method

A LED packaging and high-power technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems that are difficult to meet large-scale, stable and reliable production requirements, dispensing uniformity, and unsatisfactory glue volume. High cost of materials and other issues, to achieve the effect of stable and reliable dispensing quality, stable and reliable quality, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

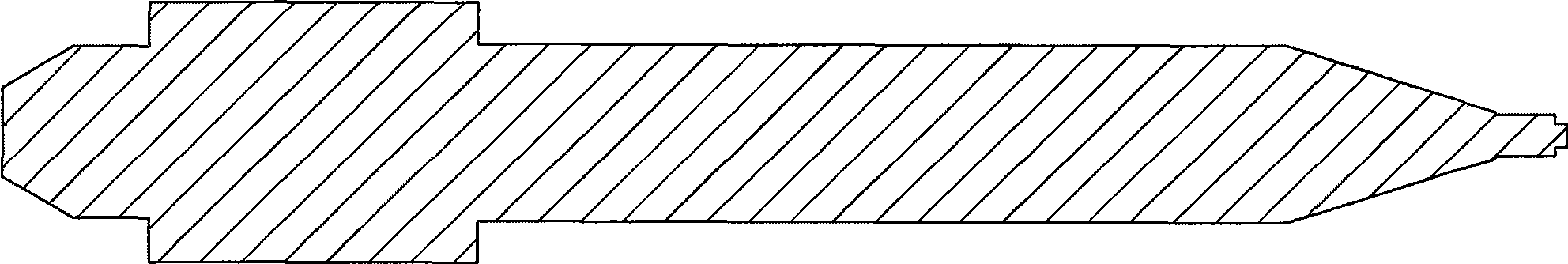

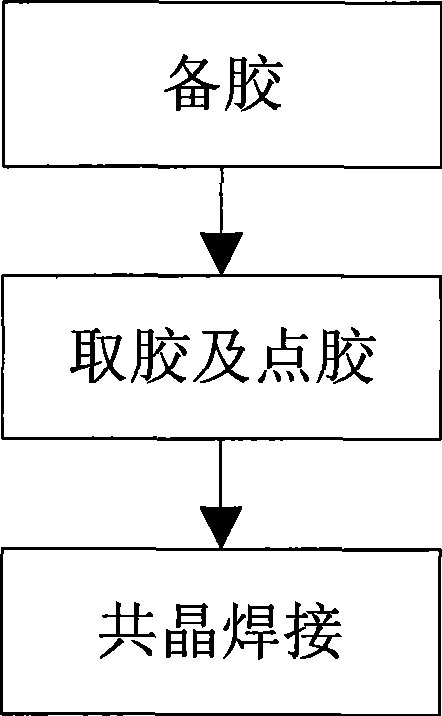

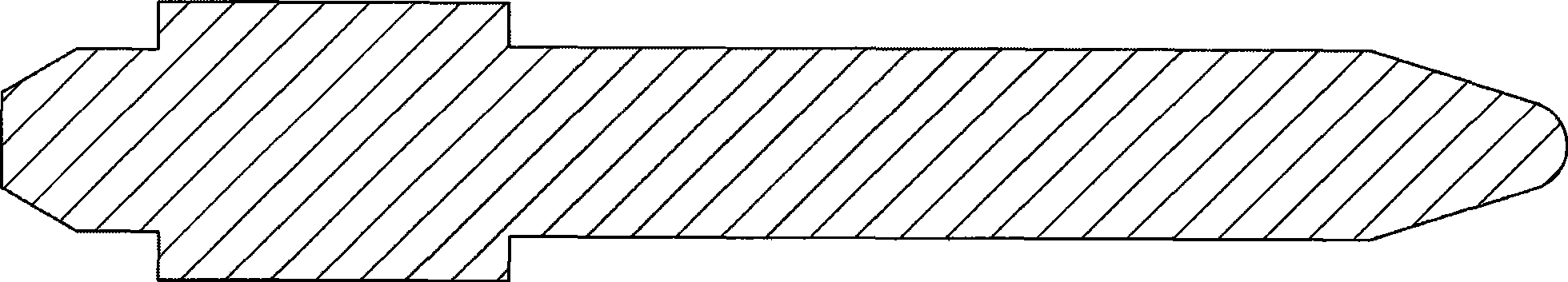

[0023] Such as figure 2 As shown, the present invention provides a high-power LED package die-bonding method, comprising the following steps:

[0024] In the glue preparation step, put eutectic solder paste as a solid crystal material in the glue tray, and the eutectic solder paste can use a variety of common solder pastes, such as any one of the following solder pastes: Sn 96.5 Ag 3.0 Cu 0.5 , Sn 95.5 Ag 4.0 Cu 0.5 , Sn 96.5 Ag 3.5 , Sn 63 Pb 37 , Sn 42 Bi 58 , the surface of the solder paste on the part where the glue is to be taken is smoothed by the scraper of the rubber plate;

[0025] In the glue taking and dispensing steps, use a blunt dispensing head to dip the solder paste from the glue tray, and then attach the removed solder paste to the base to fix the LED chip's solid crystal position;

[0026] In the eutectic soldering step, place the LED chip with a metal layer on the bottom surface at the crystal-bonding position with solder paste on the base, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com