Laser processing method and laser processing apparatus

A laser processing method and laser beam technology, applied in metal processing, laser welding equipment, metal processing equipment and other directions, can solve problems such as low productivity and low processing efficiency, and achieve the effect of high-efficiency laser processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention uses the following structure to achieve efficient processing when laser beams different in intensity and wavelength are irradiated in multiple stages in pattern formation of electronic circuit boards.

[0041] In the present invention, as the plurality of laser beams and the workpiece are moved relative to each other, the irradiation positions of the laser beams are also changed according to their relative movement, so the laser beams irradiate the workpiece in order of different wavelengths and intensities as described above.

[0042] use Figure 1 to Figure 3 Preferred embodiments of the present invention will be described in detail.

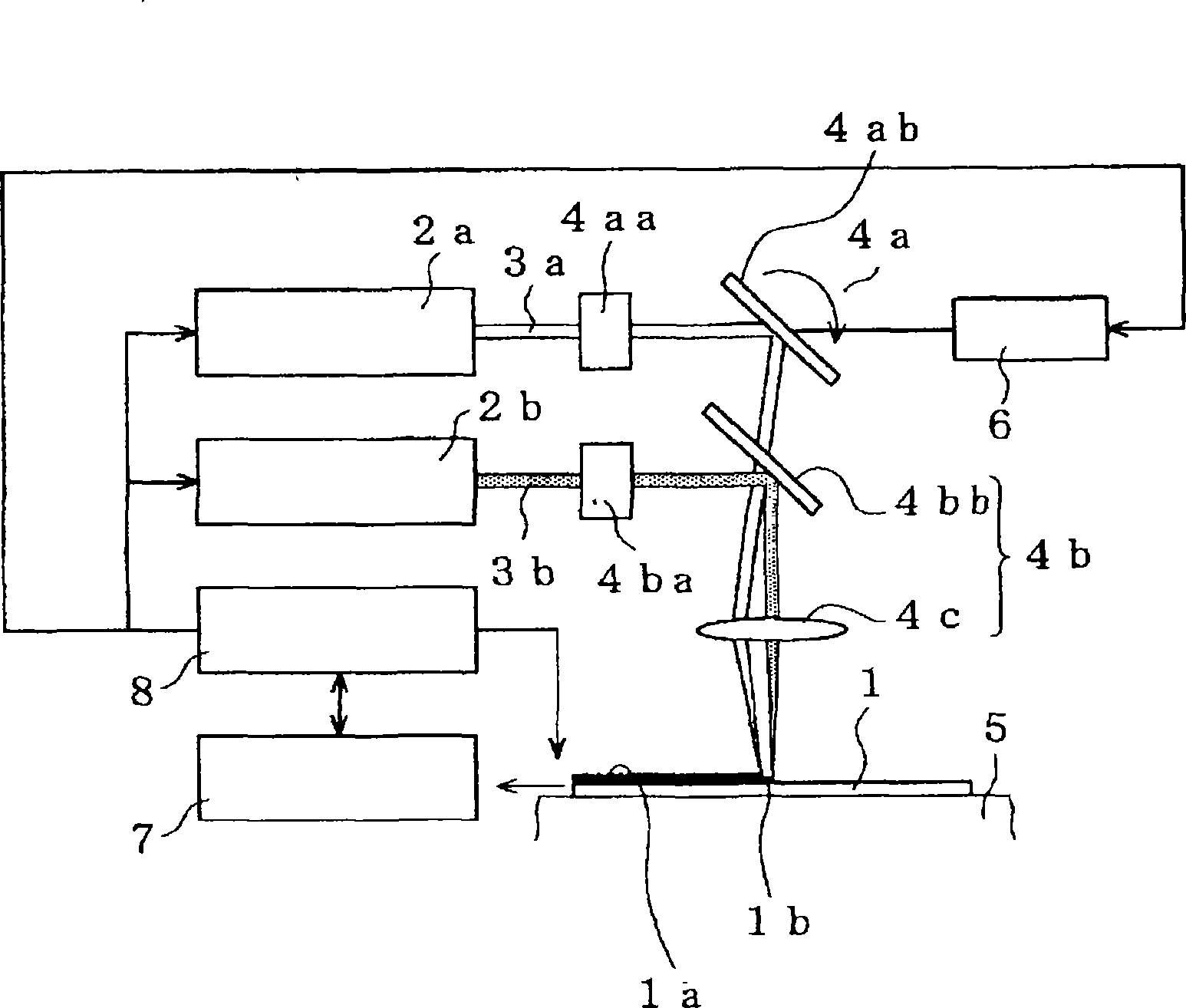

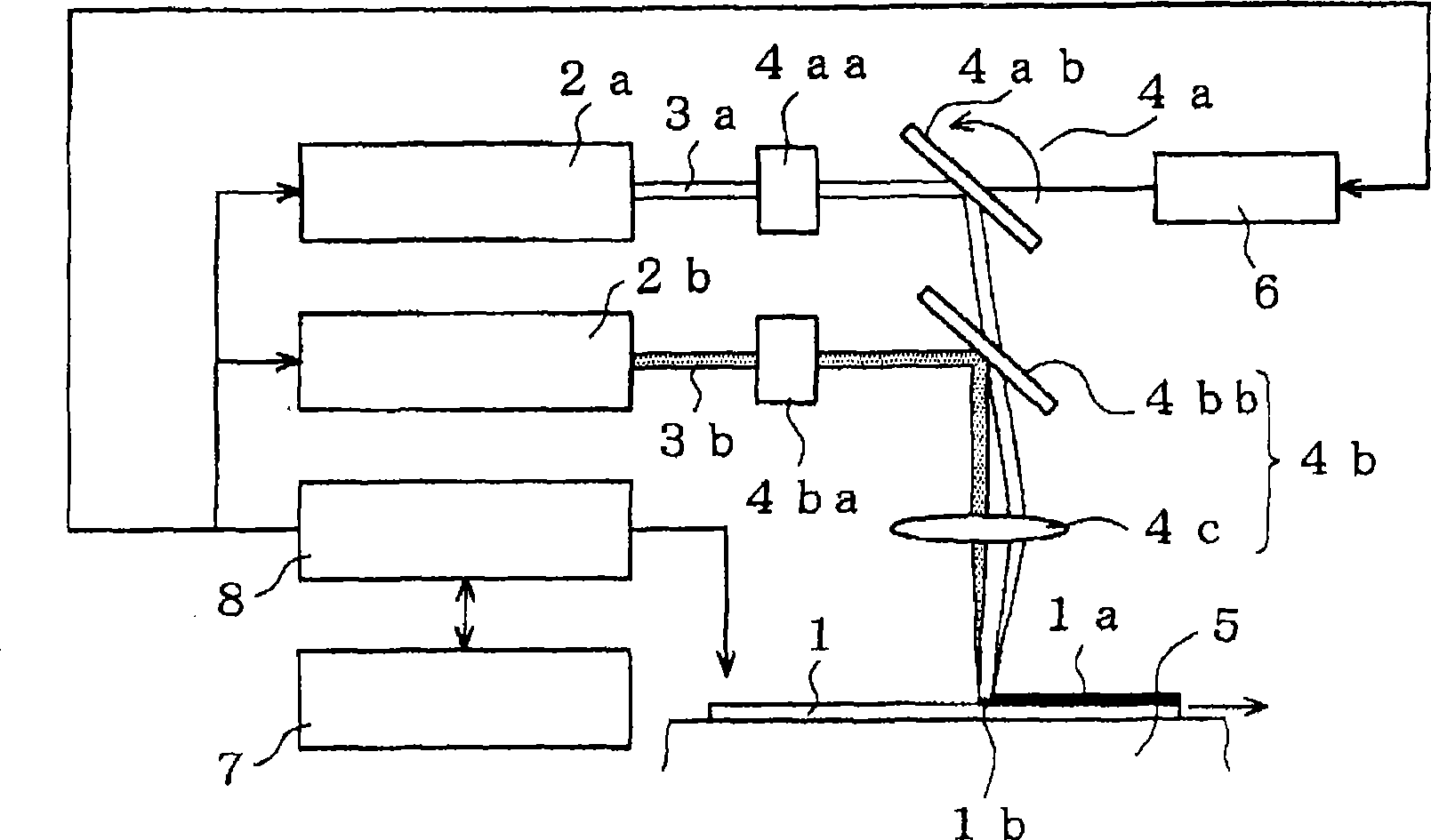

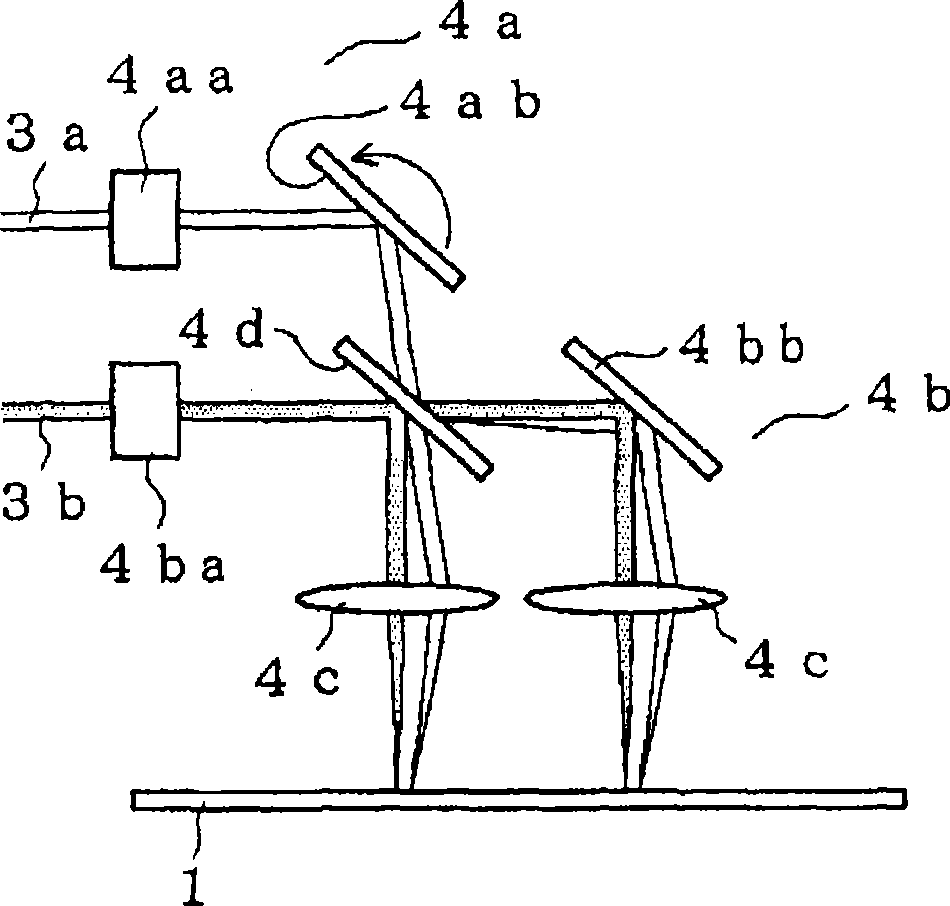

[0043] figure 1 It is an example showing the basic structure of the laser processing apparatus of this invention. figure 2 yes figure 1 The laser processing device of the present invention, but shows its moving direction and figure 1 The opposite situation. image 3 It is a schematic diagram explaining anothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com