Mesoporous TiO2 supported V2O5 catalyst with high specific surface area as well as preparation method and use thereof

A high specific surface area, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high reaction temperature, low catalytic activity, selectivity and Problems such as poor catalyst stability, to achieve the effect of high yield and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

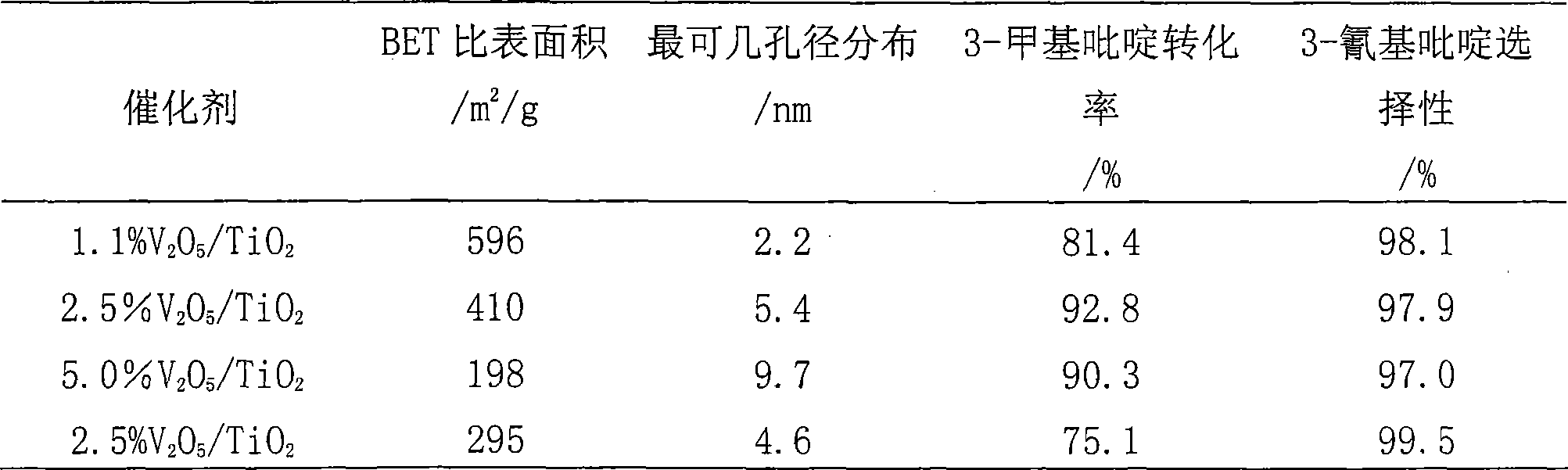

[0016] 1.1% mesoporous V 2 o 5 / TiO 2 Catalyst preparation, characterization and catalytic performance

[0017] 16.0g of tetraethylpropoxytitanium, 0.136g of triisopropoxyvanadyl and 11.0g of decaamine were dissolved in 80g of deionized water at a temperature of 273K, and then the above-mentioned mixing was adjusted with a concentration of 0.1mol / L HCl solution When the pH value of the solution reaches 5, continue to stir for 12 hours, then transfer the above mixed solution to a polytetrafluoro high-pressure hydrothermal kettle, and perform hydrothermal treatment at a temperature of 343K for 3 days, and then repeatedly wash the above-mentioned solid powder with methanol and diethylene ether for 3 time, and dried at a temperature of 373K in an oven for one day, treated at 453K in a vacuum oven for 10 days, then extracted the template agent in the solid powder with p-toluenesulfonic acid, and finally treated the above powder at 373K in an oven Dry for 2 hours and bake at 523K...

Embodiment 2

[0020] 2.5% mesoporous V 2 o 5 / TiO 2 Catalyst preparation, characterization and catalytic performance

[0021] 16.0g of tetraethylpropoxytitanium, 0.310g of triisopropoxyvanadyl and 14.1g of dodecylamine were dissolved in 100g of deionized water at a temperature of 273K, and the above-mentioned When the pH value of the mixed solution reaches 4, continue to stir for 12 hours, then transfer the above mixed solution to a PTFE high-pressure hydrothermal kettle, conduct hydrothermal treatment at a temperature of 353K for 3 days, and then repeatedly wash the above-mentioned solid powder with methanol and diethyl ether 3 times, and dried at 373K in an oven for one day, and treated at 453K in a vacuum oven for 10 days, then extracted the template agent in the solid powder with p-toluenesulfonic acid, and finally treated the above powder at 383K in an oven Drying at low temperature for 2 hours and sintering at 553K in a muffle furnace for 2 hours to obtain 2.5% mesoporous V 2 o 5...

Embodiment 3

[0024] 5.0% mesoporous V 2 o 5 / TiO 2 Catalyst preparation, characterization and catalytic performance

[0025] 16.0g of tetraethylpropoxytitanium, 0.636g of triisopropoxyvanadyl and 16.2g of tetradecylamine were dissolved in 120g of deionized water at a temperature of 273K, and the above-mentioned When the pH value of the mixed solution reaches 3, continue to stir for 12 hours, then transfer the above mixed solution to a PTFE high-pressure hydrothermal kettle, conduct hydrothermal treatment at a temperature of 363K for 3 days, and then repeatedly wash the above-mentioned solid powder with methanol and diethyl ether 3 times, and dried at 373K in an oven for one day, and treated at 453K in a vacuum oven for 10 days, then extracted the template agent in the solid powder with p-toluenesulfonic acid, and finally treated the above powder at 393K in an oven Drying at 573K for 2 hours in a muffle furnace to obtain 5.0% mesoporous V 2 o 5 / TiO 2 catalyst.

[0026] The BET speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com