Catalyst for producing 3-cyano pyridine as well as preparation method and use thereof

A technology of cyanopyridine and catalyst, which is applied in the field of catalyst for producing 3-cyanopyridine and its preparation and application, can solve the problems of high energy consumption, high use temperature, and low energy consumption, and achieve high yield, The effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

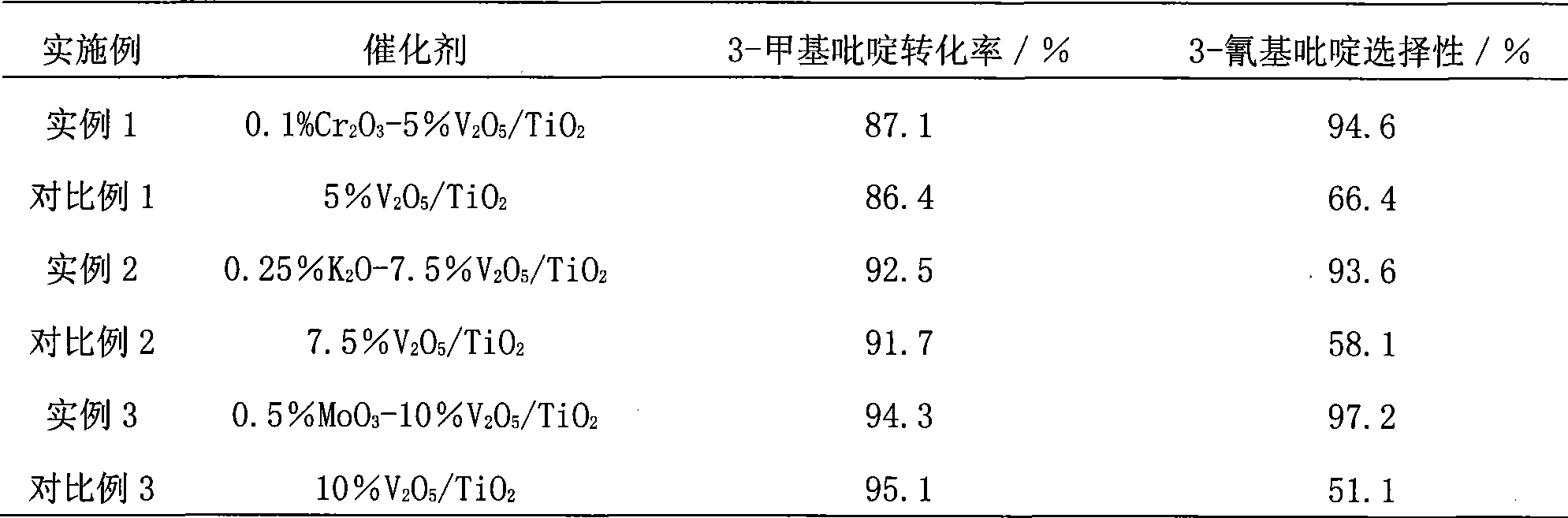

Examples

Embodiment 1

[0013] 0.1%Cr 2 o 3 -5%V 2 o 5 / TiO 2 Catalyst preparation

[0014] Weigh NH 4 VO 3 1.084g, dissolved in 60.0g double-distilled water and 1.668g oxalic acid mixture, heated and stirred to 50°C for NH 4 VO 3 Dissolve completely, then add 0.0894g Cr 2 o 3 , forming an orange liquid, and the solution was gradually cooled to 20 ° C, at this temperature, slowly added 16 g of anatase TiO with a particle size of 100 mesh 2 Add the solid powder in the above solution, continue to stir to form a suspension, and adjust the pH value of the above slurry to 6 with an appropriate amount of oxalic acid, continue to stir for 12 hours, and then evaporate the solvent to dryness at 90°C for the resulting suspension. Dry at ℃ for 12h, place in a muffle furnace and bake at 400℃ for 5h to obtain a sample with 0.1% Cr 2 o 3 -5%V 2 o 5 / TiO 2 catalyst.

[0015] Weigh 0.5 g of the above-mentioned solid catalyst and apply it to the gas-phase ammoxidation of 3-picoline to produce 3-cyanop...

Embodiment 2

[0017] 0.25%K 2 O-7.5%V 2 o 5 / TiO 2 Catalyst preparation and catalytic performance

[0018] Weigh NH 4 VO 3 1.668g, dissolved in 60.0g double-distilled water and 1.668g oxalic acid mixture, heated and stirred to 70°C for NH 4 VO 3 Dissolve completely, then add 0.0927g KNO 3 , forming an orange liquid, and the solution was gradually cooled to 50 ° C, at this temperature, slowly added 16 g of anatase TiO with a particle size of 140 mesh 2 Add the solid powder in the above solution, continue to stir to form a suspension, and adjust the pH value of the above slurry to 5 with an appropriate amount of oxalic acid, continue to stir for 12 hours, and then evaporate the solvent to dryness at 90°C for the resulting suspension, at 110 Dry at ℃ for 12h, place in a muffle furnace and bake at 500℃ for 7h to obtain a sample of 0.25% K 2 O-7.5%V 2 o 5 / TiO 2 catalyst.

[0019] Weighed 1 g of the above solid catalyst and applied it to the gas-phase ammoxidation of 3-picoline to p...

Embodiment 3

[0021] 0.5% MoO 3 -10%V 2 o 5 / TiO 2 Catalyst preparation and catalytic performance

[0022] Weigh NH 4 VO 3 2.298g, dissolved in 60.0g double-distilled water and 1.668g oxalic acid mixture, heated and stirred to 90°C for NH 4 VO 3 Dissolve completely, then add 0.0894gMoO3 , forming an orange liquid, and the solution was gradually cooled to 50 ° C, at this temperature, slowly added 16 g of anatase TiO with a particle size of 150 mesh 2 Add the solid powder in the above solution, continue to stir to form a suspension, and adjust the pH value of the above slurry to 3 with an appropriate amount of oxalic acid, continue to stir for 12 hours, and then evaporate the solvent to dryness at 90°C for the resulting suspension. Dry at ℃ for 12h, place in a muffle furnace and bake at 600℃ for 10h to obtain a sample of 0.5% MoO 3 -10%V 2 o 5 / TiO 2 catalyst.

[0023] Weighed 2 g of the above solid catalyst and applied it to the gas-phase ammoxidation of 3-picoline to produce 3-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com