Laser beam welding workstation

A laser welding and workbench technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of inaccurate positioning of the welding table, inaccurate workpiece positioning, poor operability, etc., and achieve good laser welding effect. , to ensure convenience and accuracy, to ensure the effect of the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

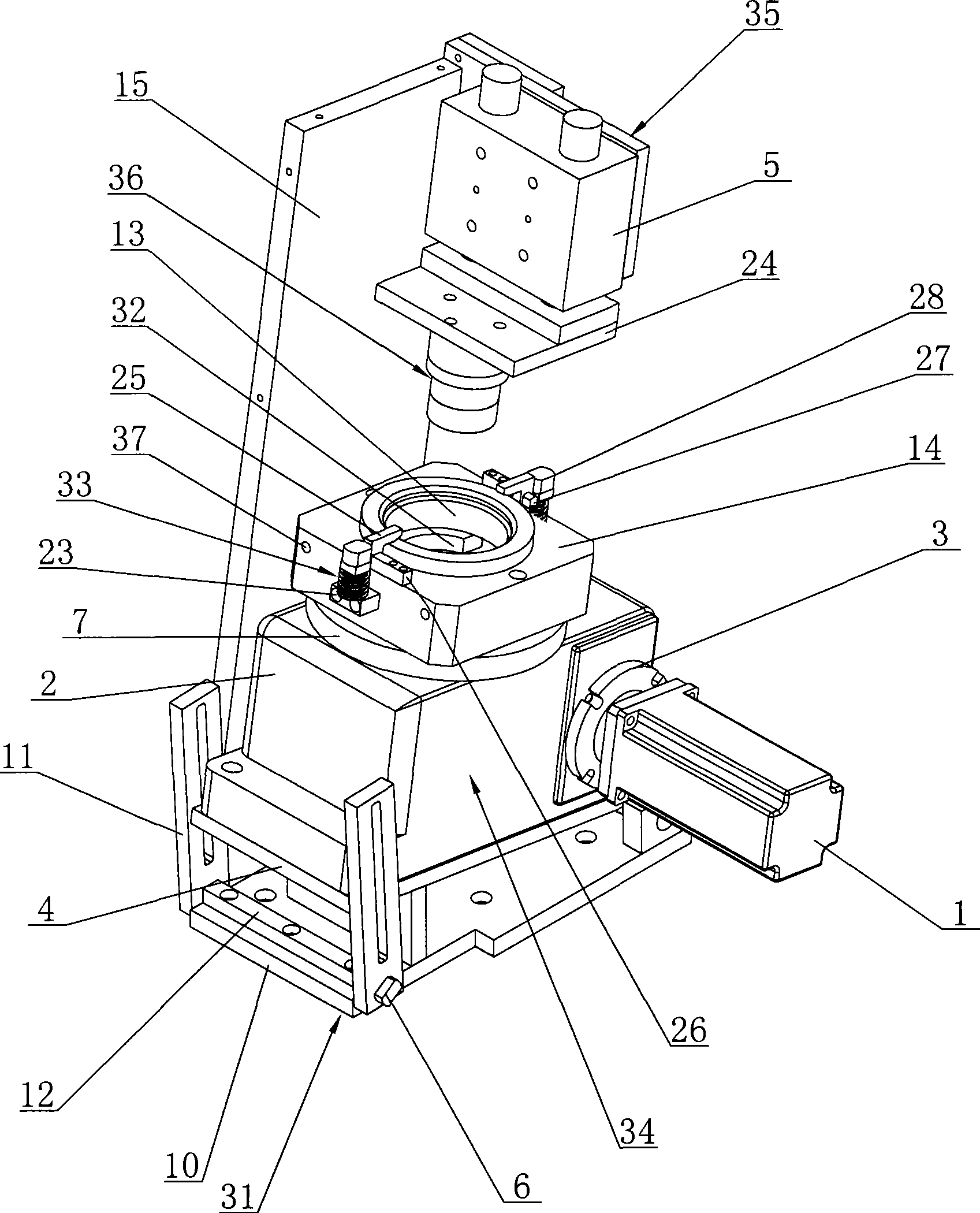

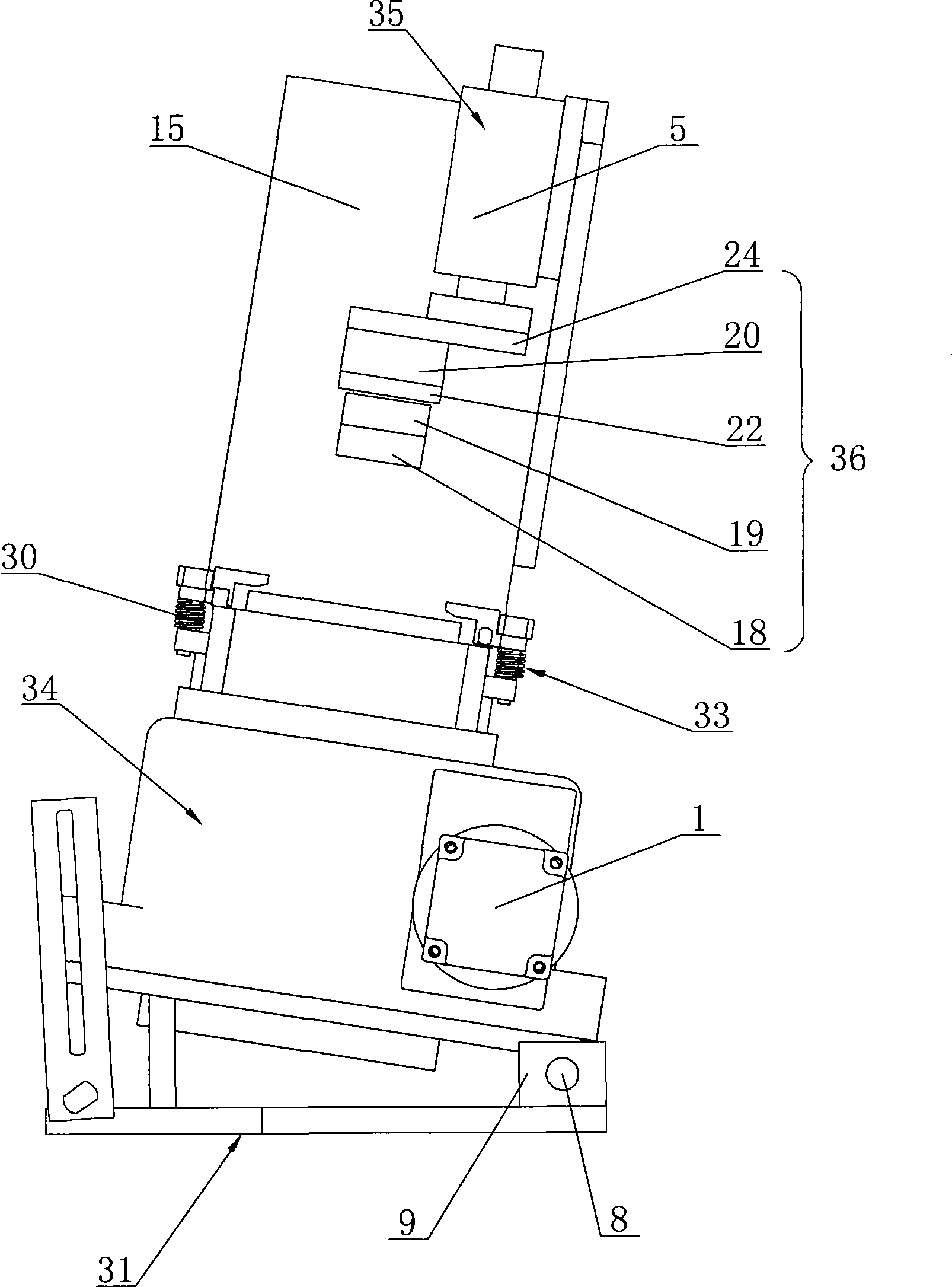

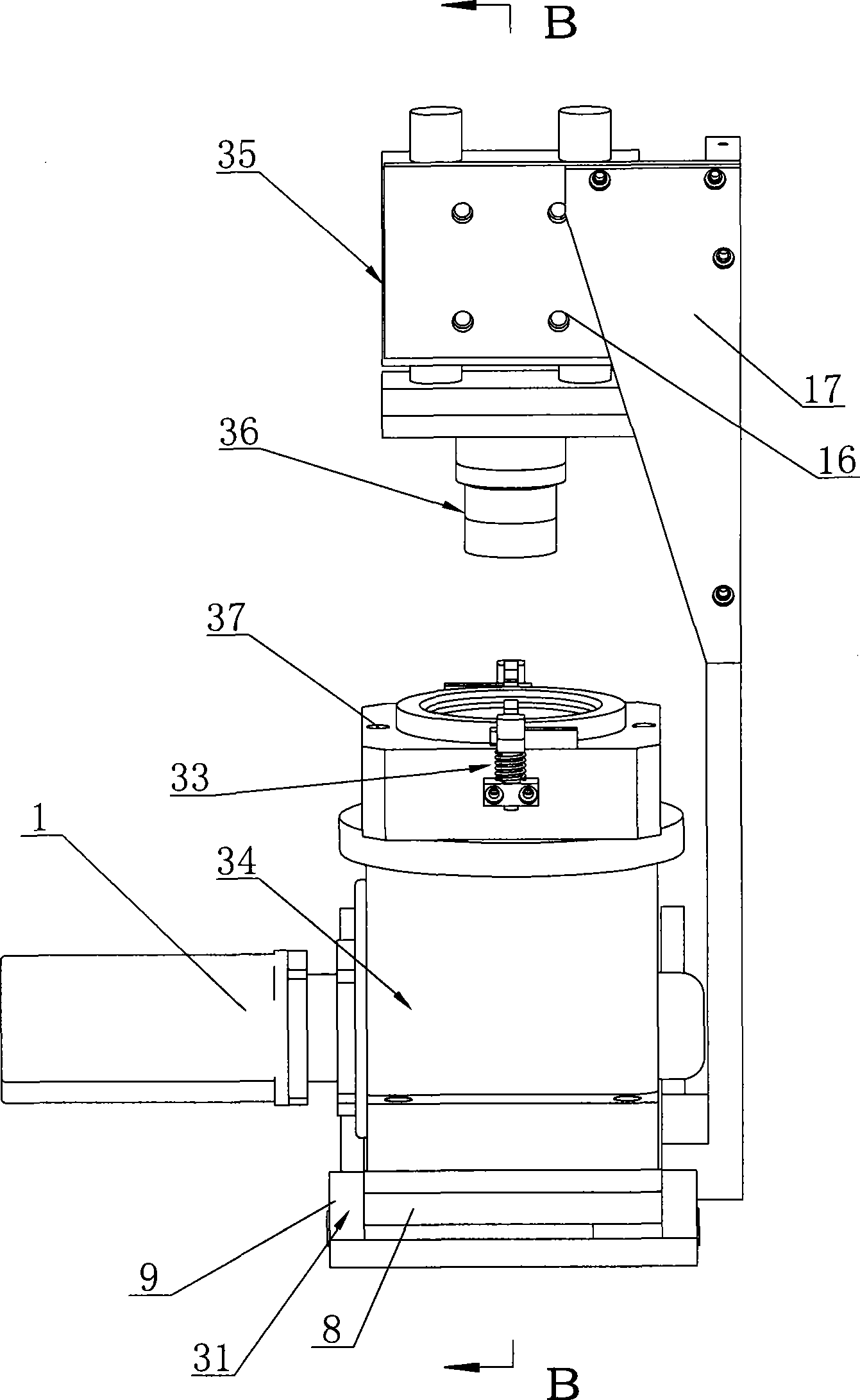

[0021] Such as figure 1 As shown, it is a three-dimensional schematic diagram of a preferred embodiment of the laser welding workbench of the present invention, figure 2 is a side view of the preferred embodiment, image 3 Rear view of the preferred embodiment, Figure 4 for image 3 The cross-sectional view of B-B direction in the middle. The laser welding workbench of the present invention is used in the laser welding system. It is a special workbench with multi-functional functions for welding circular products. The laser welding workbench in the preferred embodiment is mainly composed of a base 31 and a fixed The positioning seat 14 above the base 31 is composed of a driving device 34 and a pressing device 35 .

[0022] In this embodiment, the base 31 includes a base plate 10 and a swivel seat 4 arranged on the base plate 10, the base plate 10 is horizontally arranged, the angle between the swivel base 4 and the base plate 10 is adjustable, the positioning seat 14, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com