Platform for driving straight line motor of PCB piercing machine

A linear motor and drive platform technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of small heat dissipation, large thrust, affecting the performance stability and service life of load actuator components, and achieve the implementation effect Good, reduced thrust, reduced overall mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

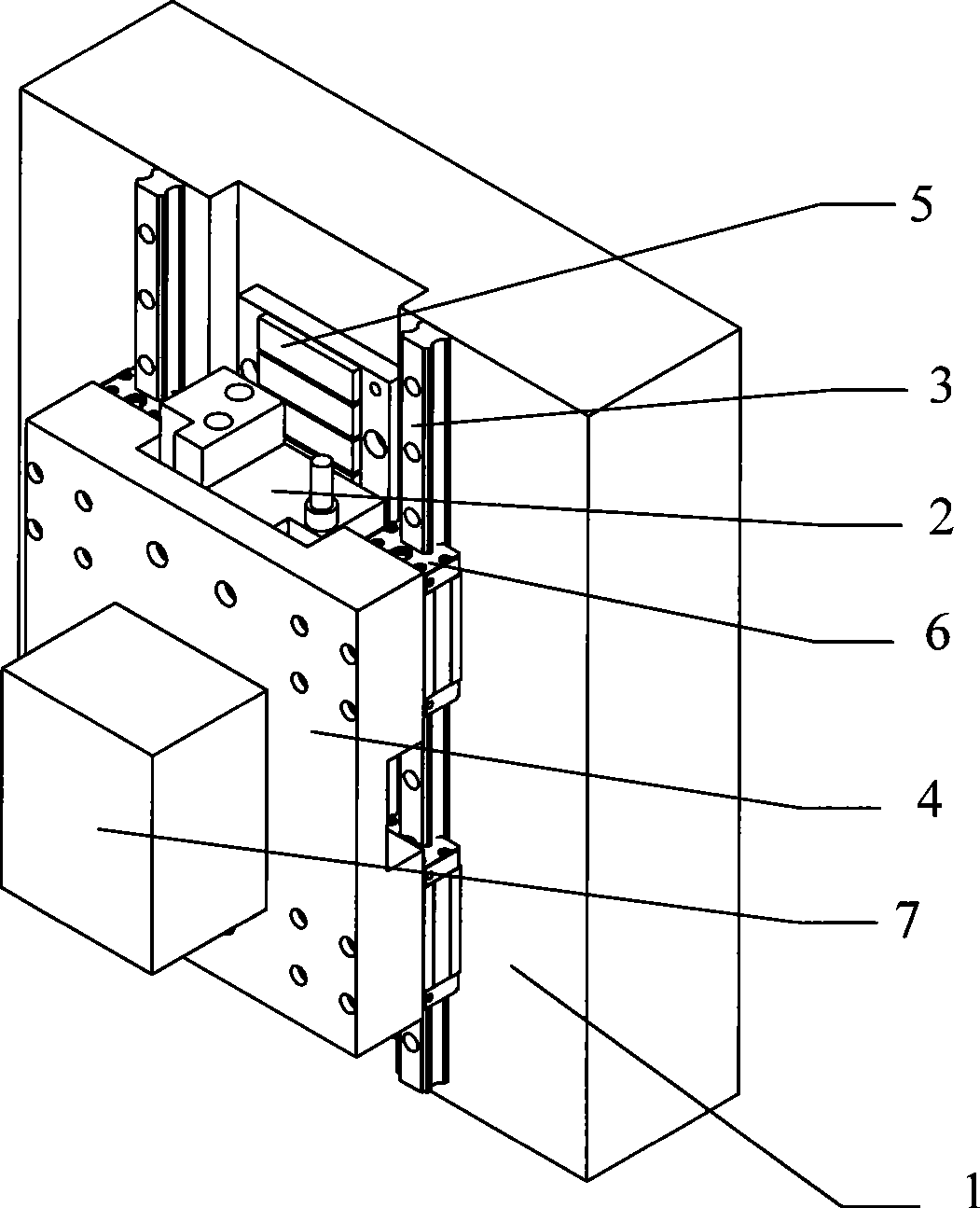

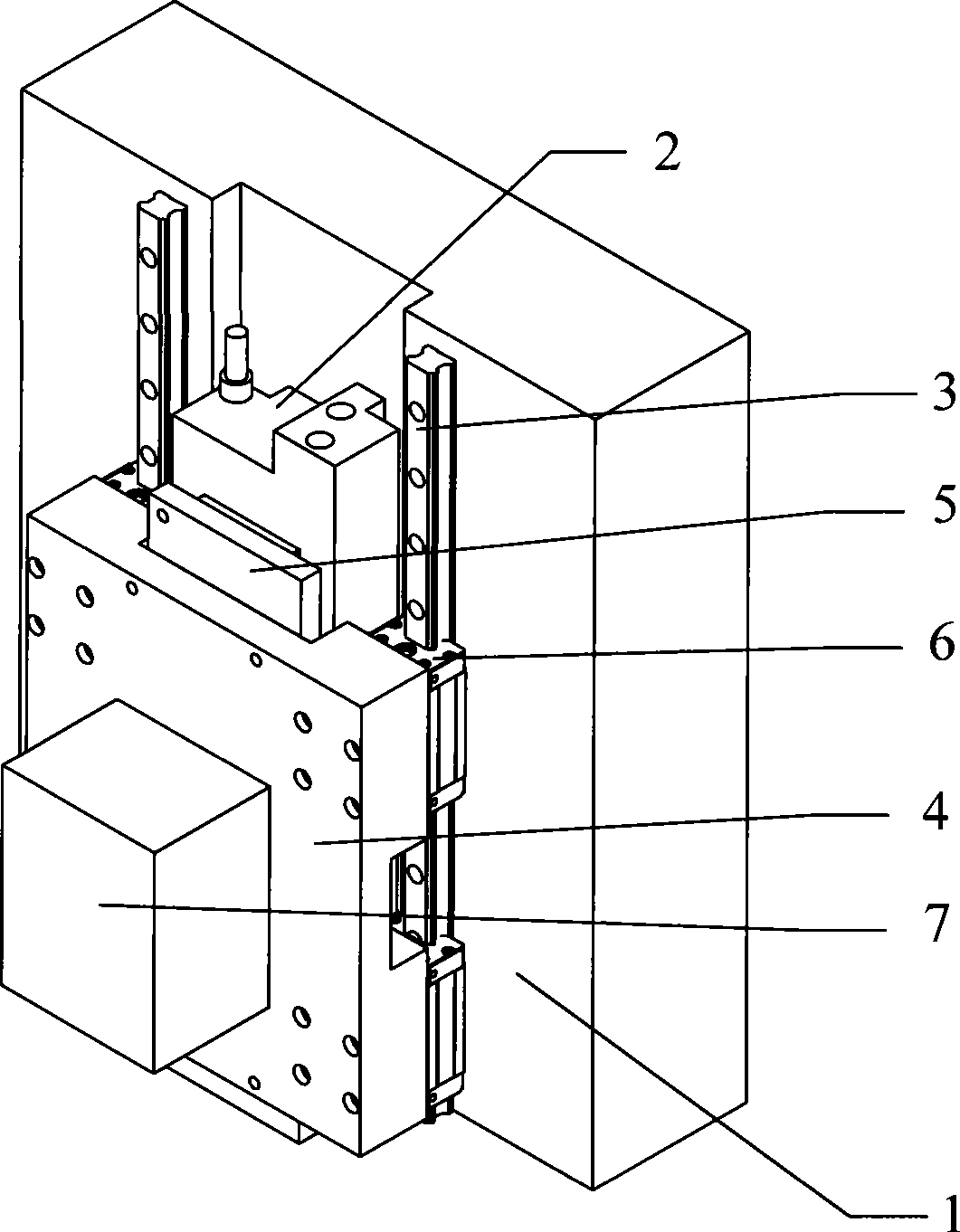

[0020] Such as figure 2 The linear motor drive platform of a PCB drilling machine shown is special in that it includes a base fixed platform 1, a motor mover 2, a guide rail 3, a fixed plate 4, a stator 5, and a slider 6, and the base fixed platform 1 is equipped with motor mover 2 and guide rail 3, the stator 5 is installed on the movable fixed plate 4, the fixed plate 4 is installed on the guide rail slider 6, and the linear motor stator 5 is driven by the electromagnetic thrust of the linear motor and fixed together. The plate 4 moves along the guide rail 3 . That is to say, the motor generates a continuous and constant moving magnetic field thrust after the AC power is connected, and then pushes the fixed plate 4, the stator 5 and the load 7 installed during use to move. At the same time, the base fixed platform 1 is provided with an installation plane on which the linear motor mover 2 is installed, and the guide rails 3 are installed in pairs on both sides of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com