Coal mine low concentration mash gas methane destroying method and apparatus

A low-concentration gas and destruction device technology, applied in combustion methods, gas emissions, safety devices, etc., can solve problems such as inability to handle, use, poor air permeability, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

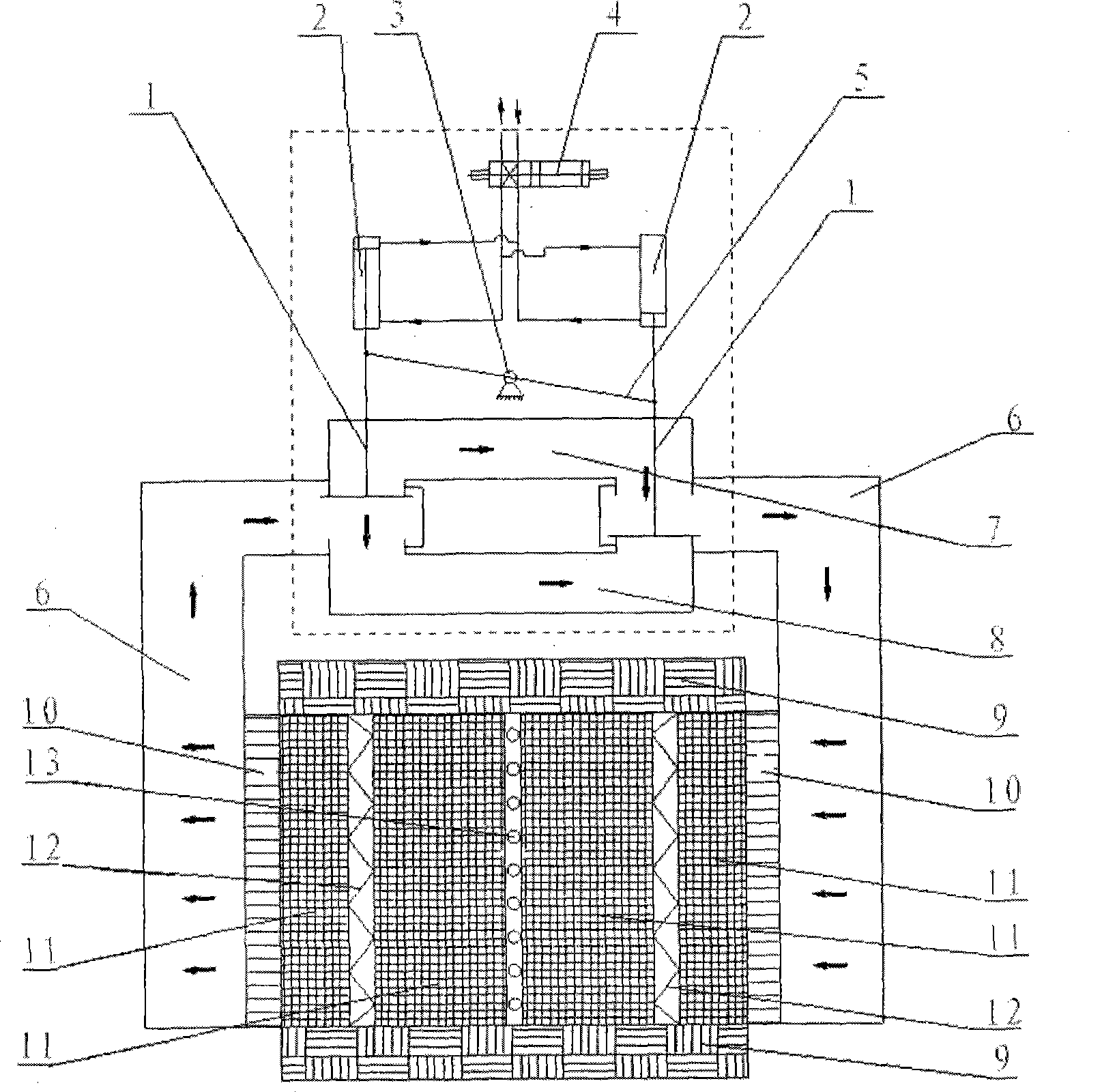

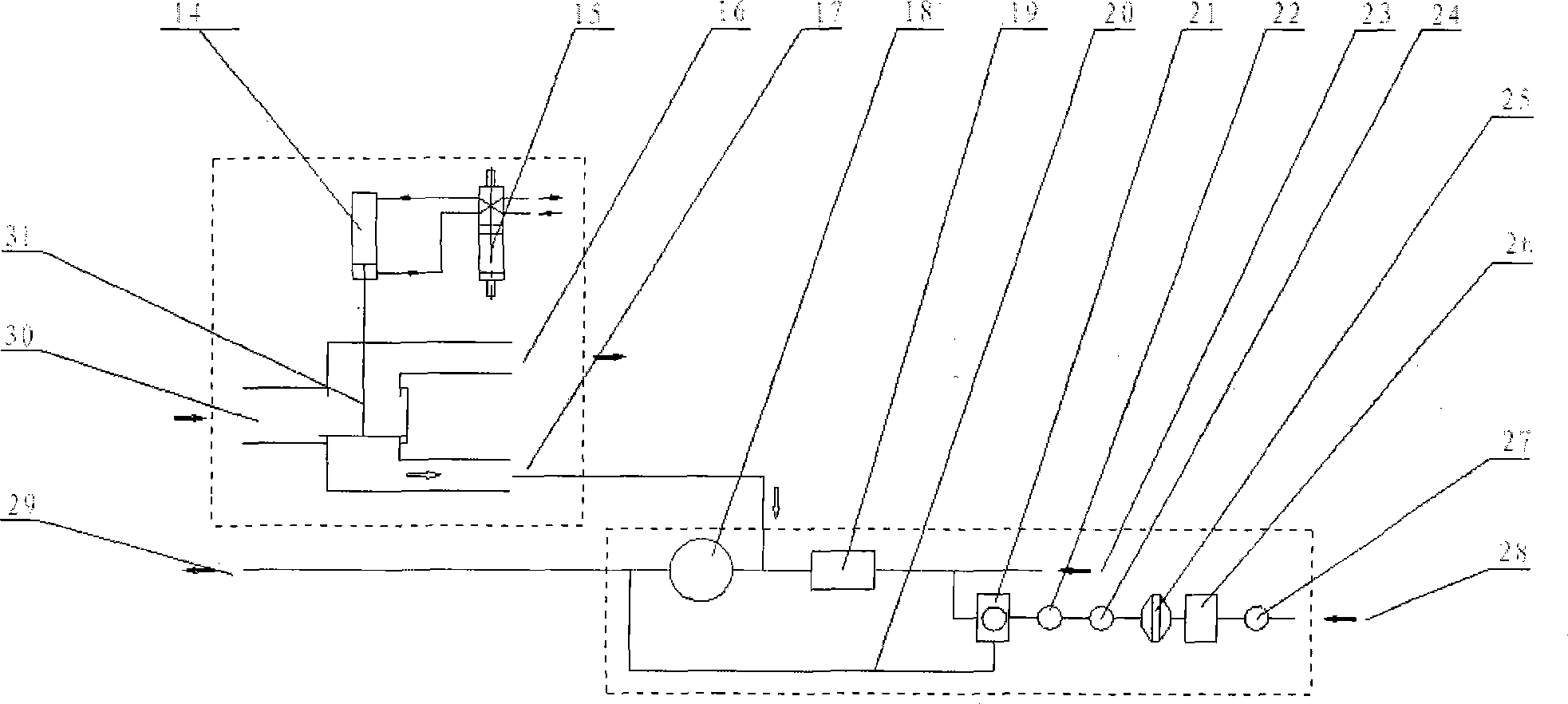

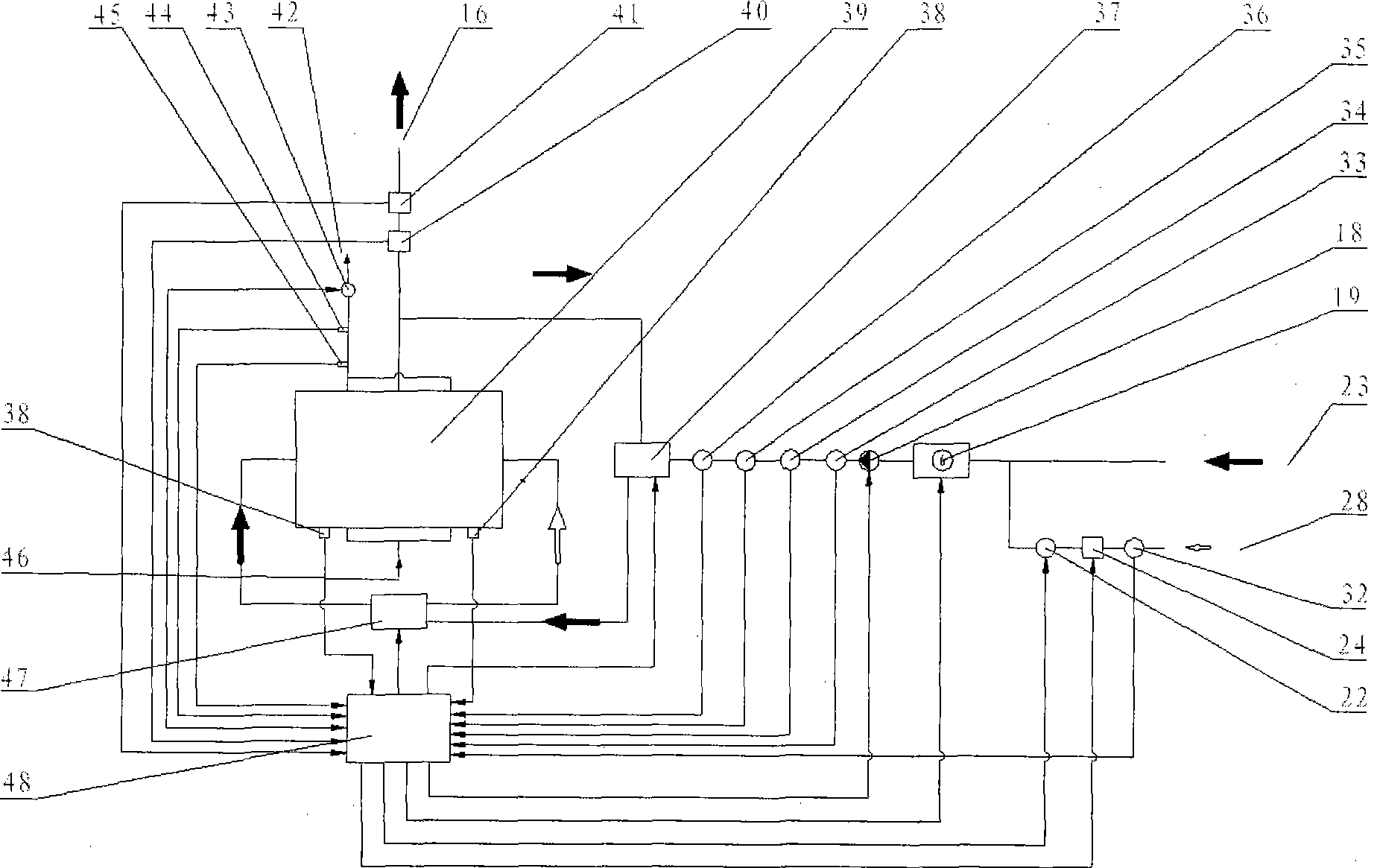

[0017] A method for destroying low-concentration methane gas in coal mines, including using a special device and performing start-up heating and oxidation reactions therein, characterized in that the use of special devices and performing start-up heating and oxidation reactions therein is in a coal mine low-concentration methane gas destruction device In the process, it is controlled by the operation detection and control system, and is automatically carried out through the following steps: (A) firstly energize and heat the oxidation bed of the device to create an environment for methane oxidation reaction, and start heating to at least 800°C; Methane is input into the oxidation bed, and the methane will react with oxygen rapidly and release heat; (C) the heat storage body of the device stores the heat; (D) the clean exhaust gas after the reaction is discharged from the oxidation bed; (E) switch direction, Then input low-concentration coal mine gas methane into the oxidation be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com