Coating film drying method and coating film drying apparatus

A drying method and technology of drying device, which are applied in the directions of drying gas arrangement, body drying, drying of solid materials, etc., can solve the problems of the influence of the surface state of the coating film, the early hardening of the coating film of the outer plate, and the inability to release steam, so as to reduce the drying time. Increases, inhibits hardening, and inhibits damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

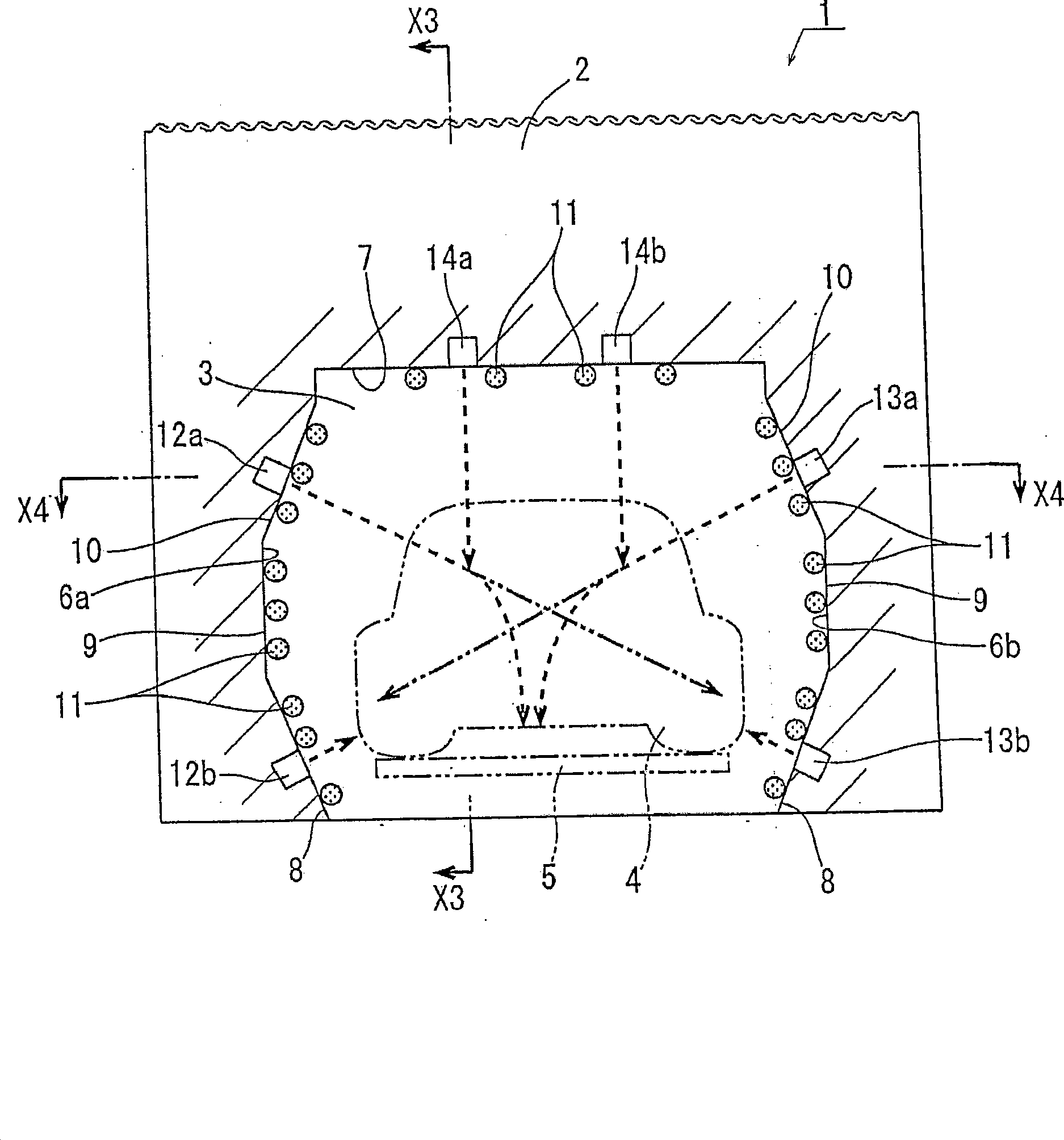

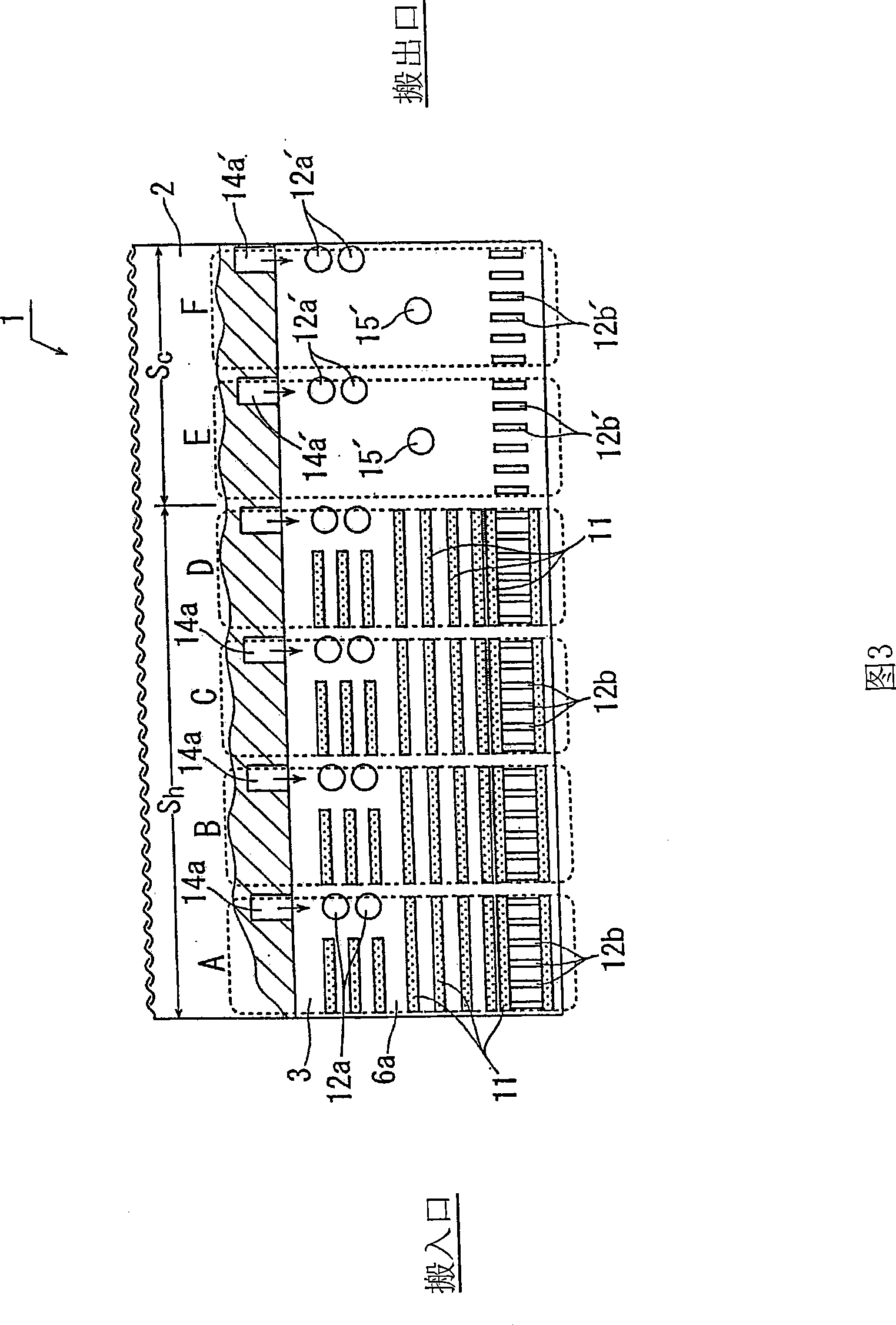

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

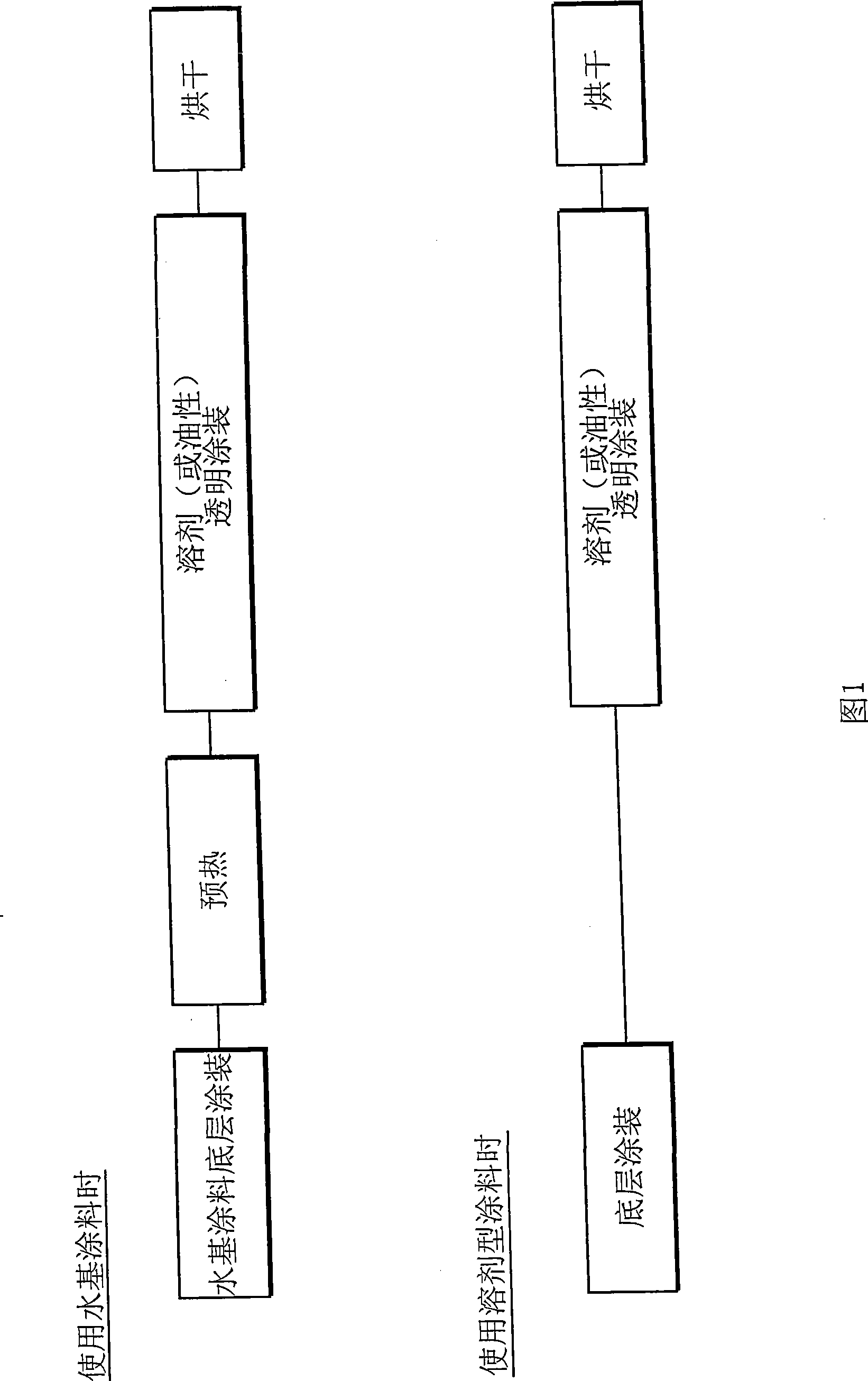

[0036]In the field of body painting, the use of volatile organic solvents is decreasing day by day. For example, in the exterior coating process of a car body, as shown in Figure 1, when using a solvent-based paint, a primer coating process, a clear coating process, and a drying process are performed, while using a water-based paint In this case, in order to dry the water-based paint film before the clear coating process, it is necessary to insert a preheating process (including a cooling process) between the primer coating process and the clear coating process. The preheating process usually requires a process length of more than 4 minutes. From the perspective of saving space, it is hoped that the process can be completed in a shorter time. Next, a case where the coating drying method according to this embodiment is applied to the preheating step will be described as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com