Anti-leakage safety multiple-medicine chamber transfusion bag

A safe and anti-leakage technology, applied in the field of packaging bags, can solve the problems of infusion accidents, difficult to find, and impossible to find leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

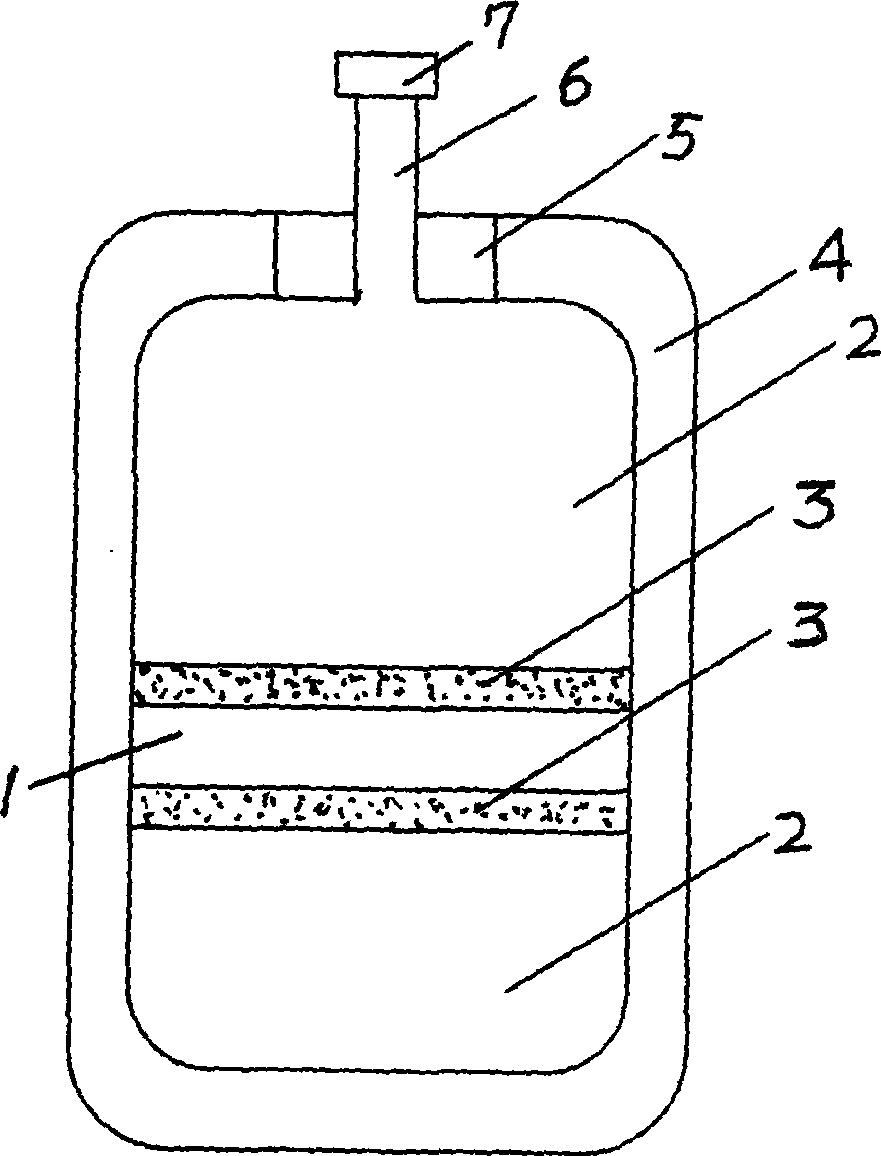

[0053] Example 1, two weak welding lines 3 are basically the same anti-leakage safety multi-chamber infusion bag

[0054] structured as figure 1 , the present embodiment infusion bag, comprises the bag body that outer edge is firmly sealed, and bag body long side is 220mm, and wide side is 120mm, and the width of bag body edge 4 firm sealing lines is 5mm; The drug inlet and outlet pipe 6 connected to the body is provided with a connecting seat 5 between the drug inlet and outlet pipe 6 and the firm sealing line, so that the drug inlet and outlet pipe 6 and the bag can be connected smoothly. Two positions 13mm and 14mm away from the wide side of the medicine inlet and outlet tube 6 are respectively provided with two weak welding lines 3 with a width of 6mm, and these two weak welding lines 3 are respectively parallel to the 120mm wide side of the bag body. Between these two weak welding lines 3 is a small spacing 1, the width of the small spacing 1 is 4mm, and the middle of th...

Embodiment 2

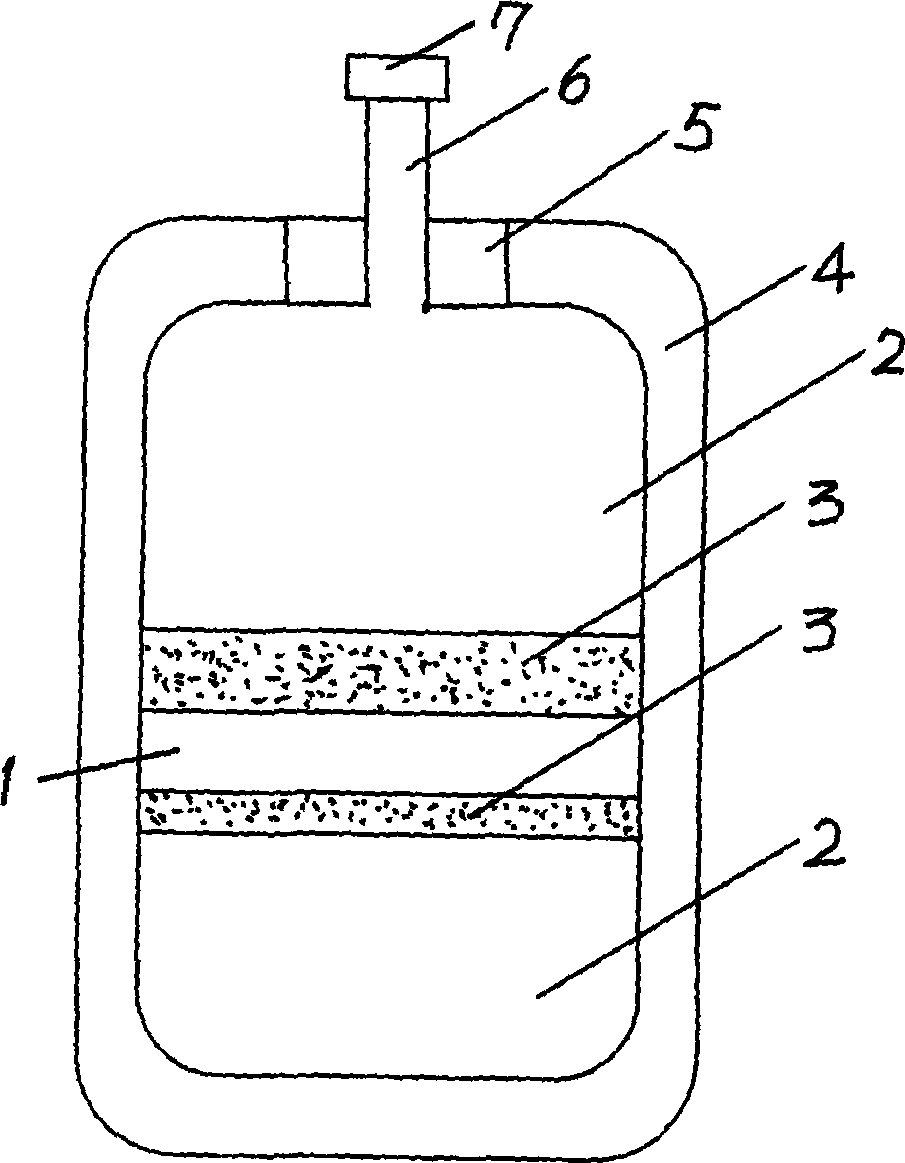

[0058] Example 2, two weak welding lines 3 with different widths, anti-leakage and safety multi-chamber infusion bag

[0059] structured as figure 2 , the width of the weak welding line 3 relying on the liquid medicine is 10mm, the width of the small spacing 1 is 5mm, the width of the weak welding line 3 relying on the solid medicine is 4mm, and the widths of the two weak welding lines 3 are different. There is a drug leakage indicator in the small space 1 between the two weak welding lines 3, and the acid-base indicator neutral red is used for the drug leakage indicator, and the color of the small space 1 is marked on the infusion bag. Why is there leakage after the color. Other structures are as in Example 1.

[0060] Other bag body structure, making bag body, filling medicine are the same as embodiment 1.

Embodiment 3

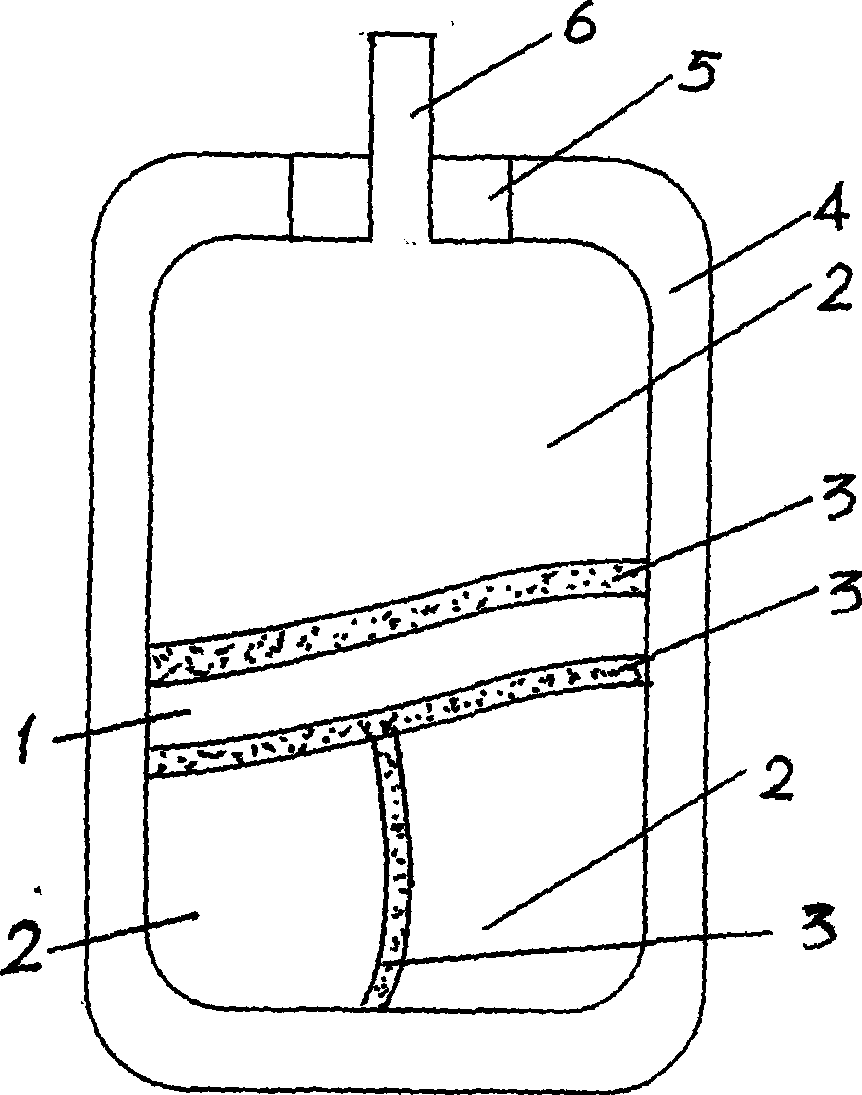

[0061] Embodiment 3, three curved weak welding lines 3 are separated into three drug chambers 2, the anti-leakage safety multi-drug chamber infusion bag

[0062] structured as image 3 , the infusion bag is divided into three medicine chambers 2, wherein, the big one medicine chamber 2 is separated from the other two small medicine chambers 2 by two curved weak welding lines 3, and a curved weak welding line is used between the two small medicine chambers 2 Line 3 separates. The medicine inlet and outlet pipe 6 is hot-pressed and fixedly sealed after being poured into the medicine. When in use, first press the liquid in the large medicine chamber by hand, untie all the three curved weak welding lines 3, mix the medicines in the three medicine chambers 2 evenly, and then use scissors to open the seal of the medicine inlet and outlet pipe 6, Patient infusion.

[0063] Other making bag body procedure, bag body structure, filling medicine, use are also the same as embodiment 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com