Method for replacing guide blade of high-efficient powder sorter

A guide vane and replacement method technology, which is applied to chemical instruments and methods, solid separation, and separation of solids from solids with airflow, etc. It can solve the problems of long production line shutdown time, increased maintenance workload, and increased shutdown losses. , to achieve the effect of reducing maintenance costs, saving labor and time, and improving maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

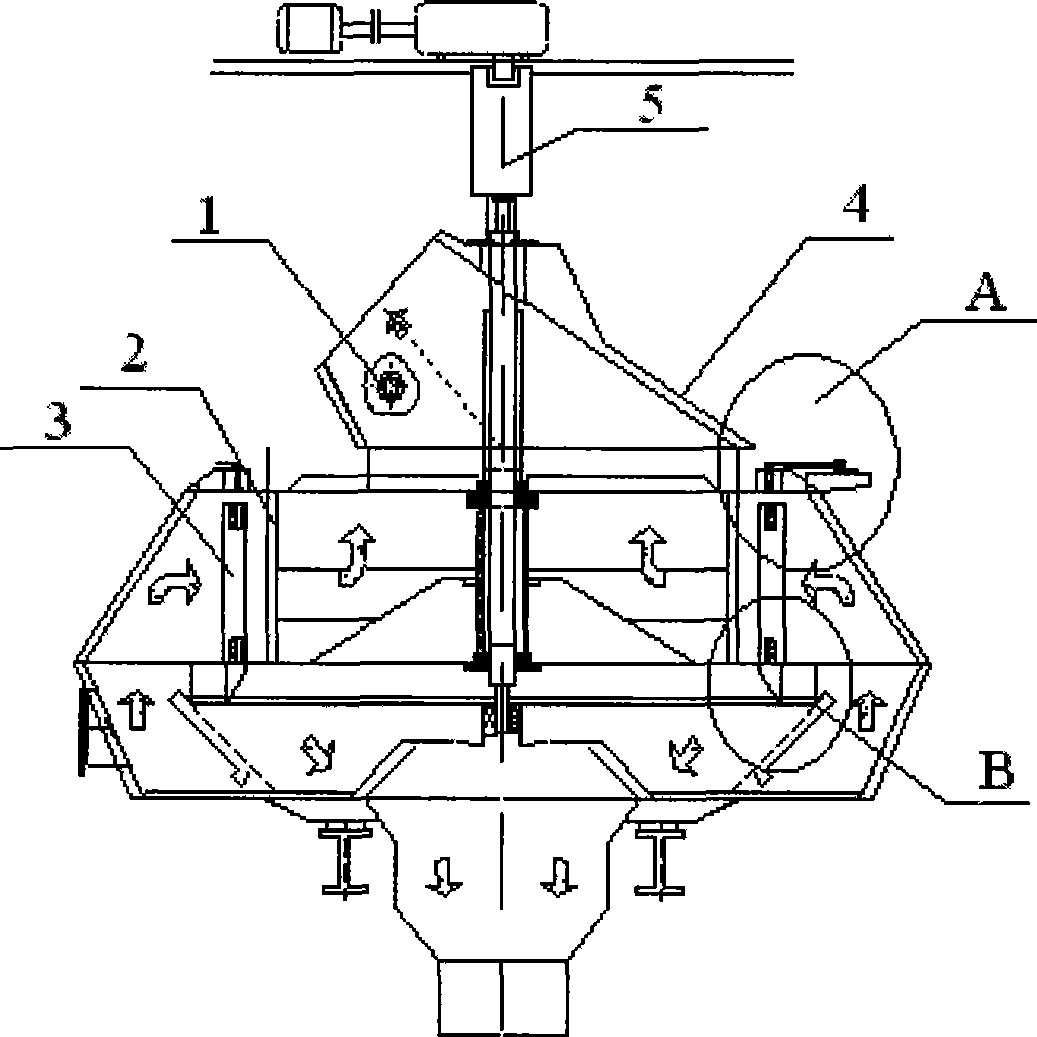

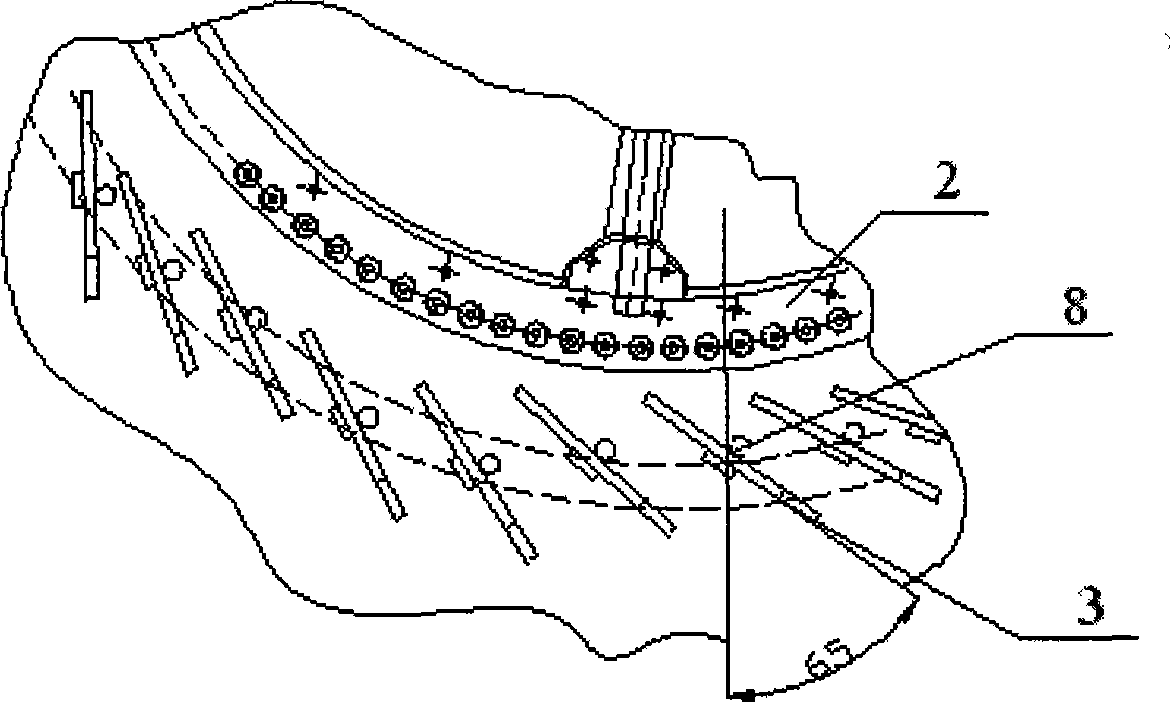

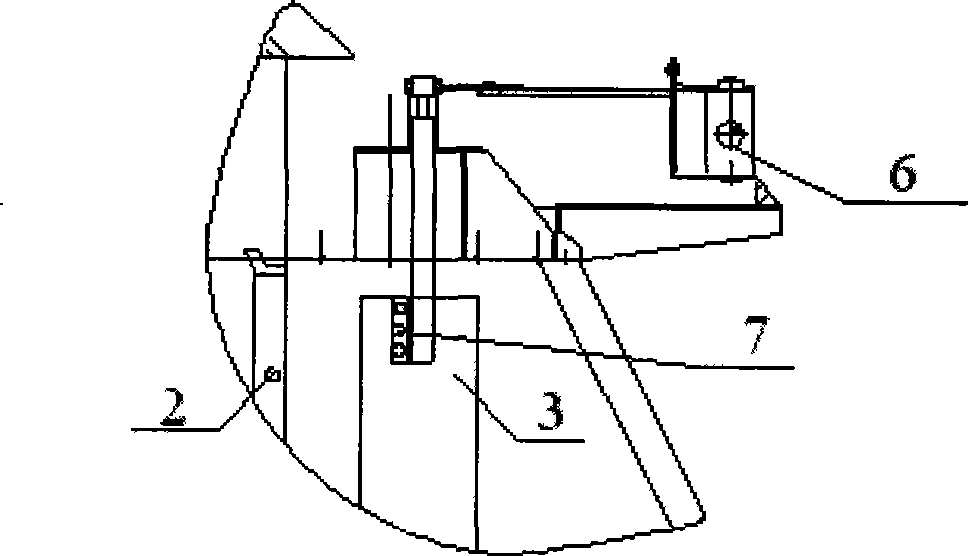

[0013] The embodiment of the present invention takes the replacement of the guide vanes of the RMS435 high-efficiency powder separator as an example, please refer to the attached Figure 1~4 . In the figure, 1 is the inspection port, 2 is the rotating blade, 3 is the vane of the guide vane, 4 is the top cover of the housing, 5 is the transmission system, 6 is the angle adjustment device, 7 is the connecting rod bolt, 8 and 9 are the socket respectively sleeve and socket shaft. Parts A and B in the figure are the upper and lower coupling mechanisms of the guide vanes respectively.

[0014] Before replacing the guide vanes, all 64 guide vanes are made separately according to the size of the original drawing, that is, the jack sleeve 8 at the bottom of the guide vanes and the vanes 3 are made separately, and then one of the vanes is decomposed into the main vane 31, the upper vane Side sub-blade 32 and lower side sub-blade 33 three parts, as attached Figure 5 shown.

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com