Three-dimensional scanner of full automatic lens edge grinding machine

A technology of three-dimensional scanning and edge grinding machine, which is applied to machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., and can solve the problems of three-dimensional data processing of lenses and mirror frames.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

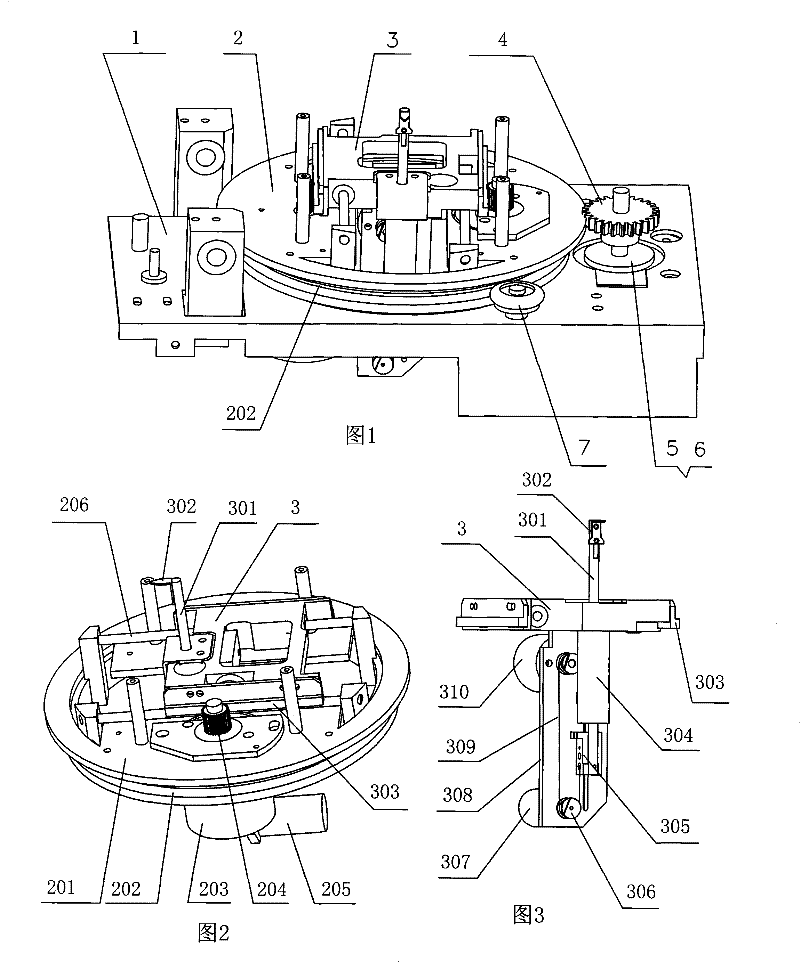

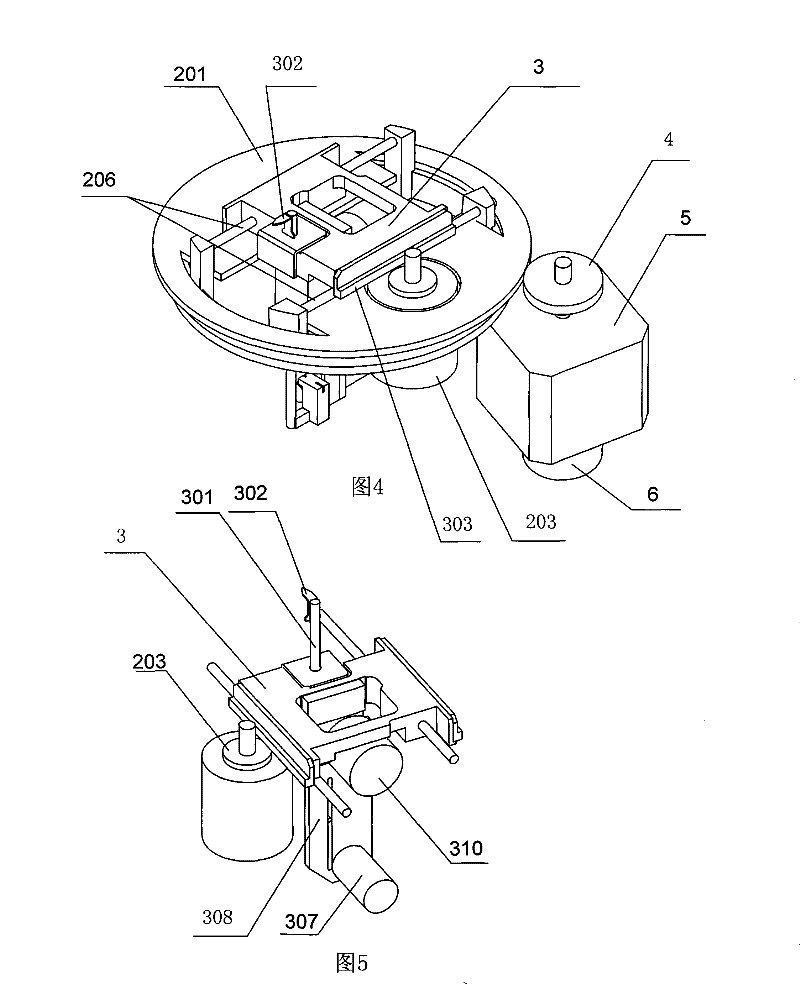

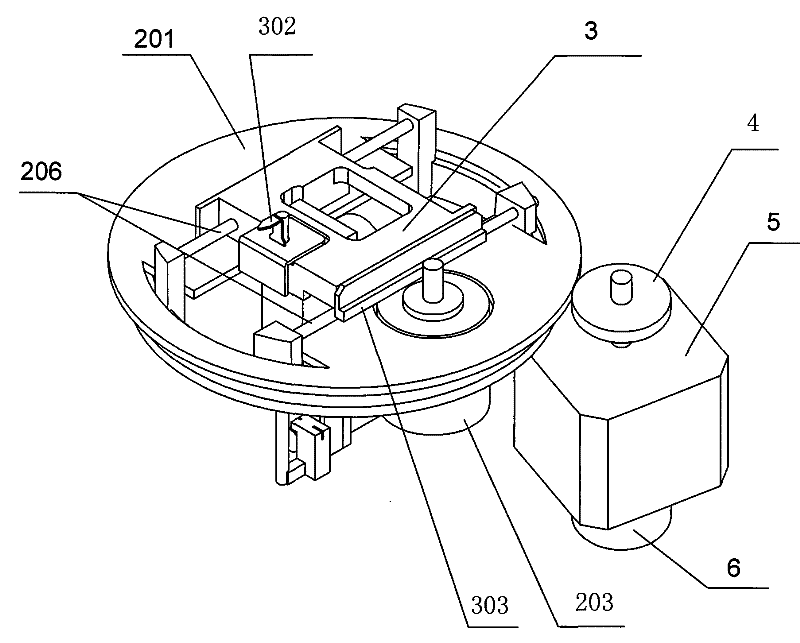

[0017] The three-dimensional scanning device of the automatic lens edging machine provided by the present invention mainly includes:

[0018] see figure 1 , figure 2 :

[0019] A base 1, which is installed in the edging machine, a set of supporting wheels 7 and a circumferential motor 5 are arranged in the base according to the concentric circle distribution, and one end of the circumferential motor 5 is connected to an encoder 6, and the other end is connected to a circumferential gear 4. The circumferential motor 5 and the encoder 6 are in figure 1 is blocked, as shown in 4. The number of the set of supporting wheels 7 is more than three, subject to the ability to support the scanning platform 2 , when the circumferential motor 5 rotates, the circumferential data can be obtained through the encoder 6 .

[0020] A disk-shaped scanning platform 2, the edge of the scanning platform is provided with gear teeth and the circumferential gear 4 on the circumferential motor to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com