A modeling method for the output shape of the material surface in the blast furnace material distribution process

A modeling method and cloth technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high requirements on the accuracy of material surface height data, unfavorable output of material surface shape, acquisition of material surface, etc. , to achieve the effect of dynamic distribution control, reducing fuel ratio and ensuring furnace conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The modeling method of the output shape of the material surface of the blast furnace material distribution process of the present invention comprises the following steps:

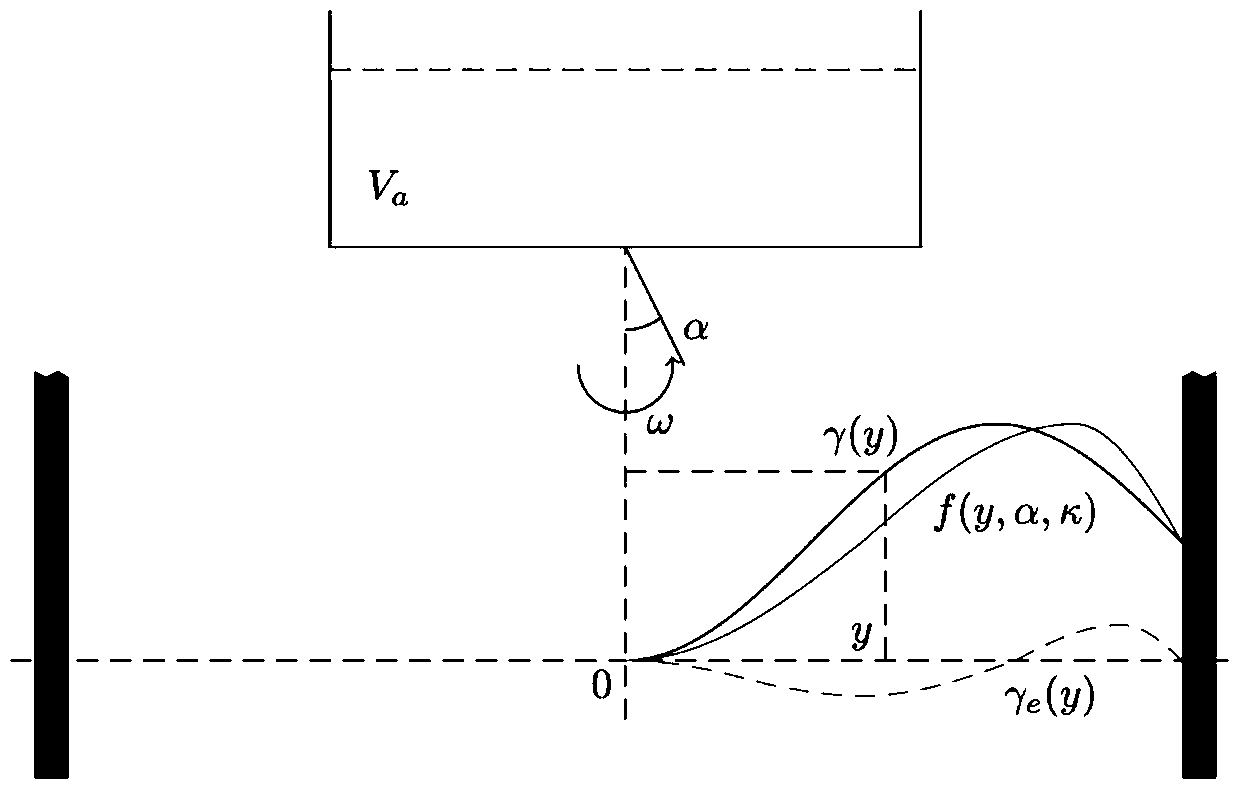

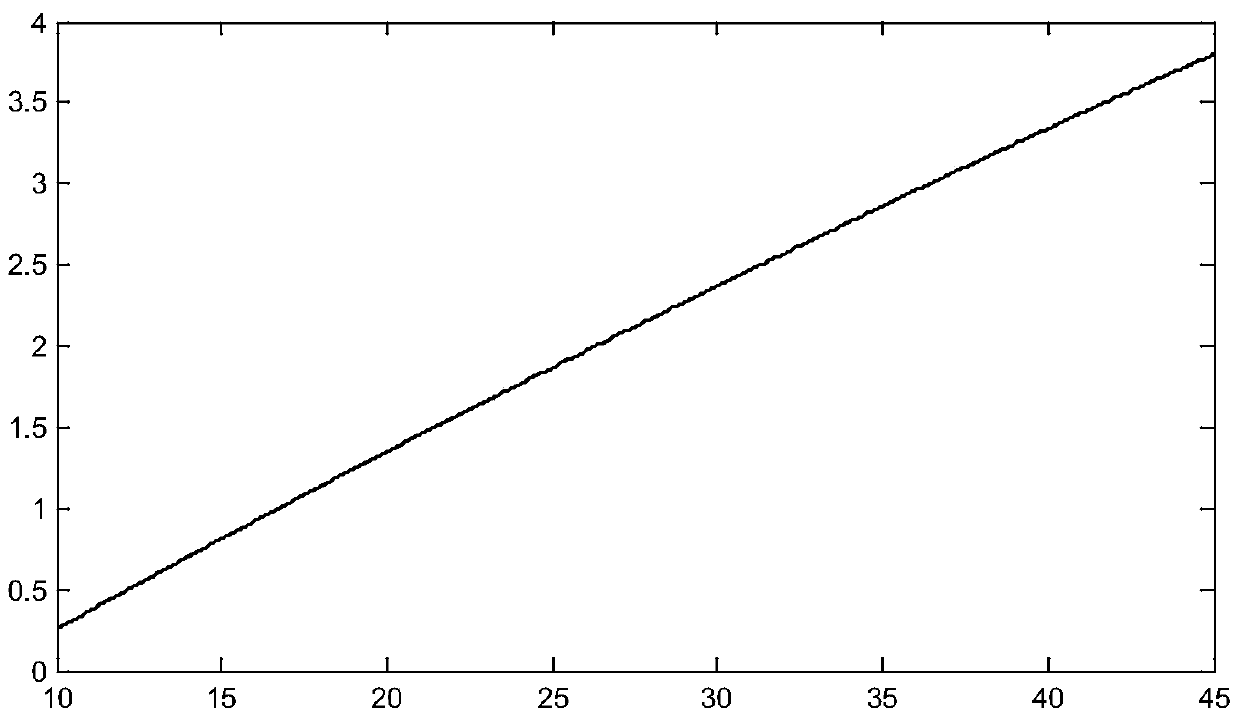

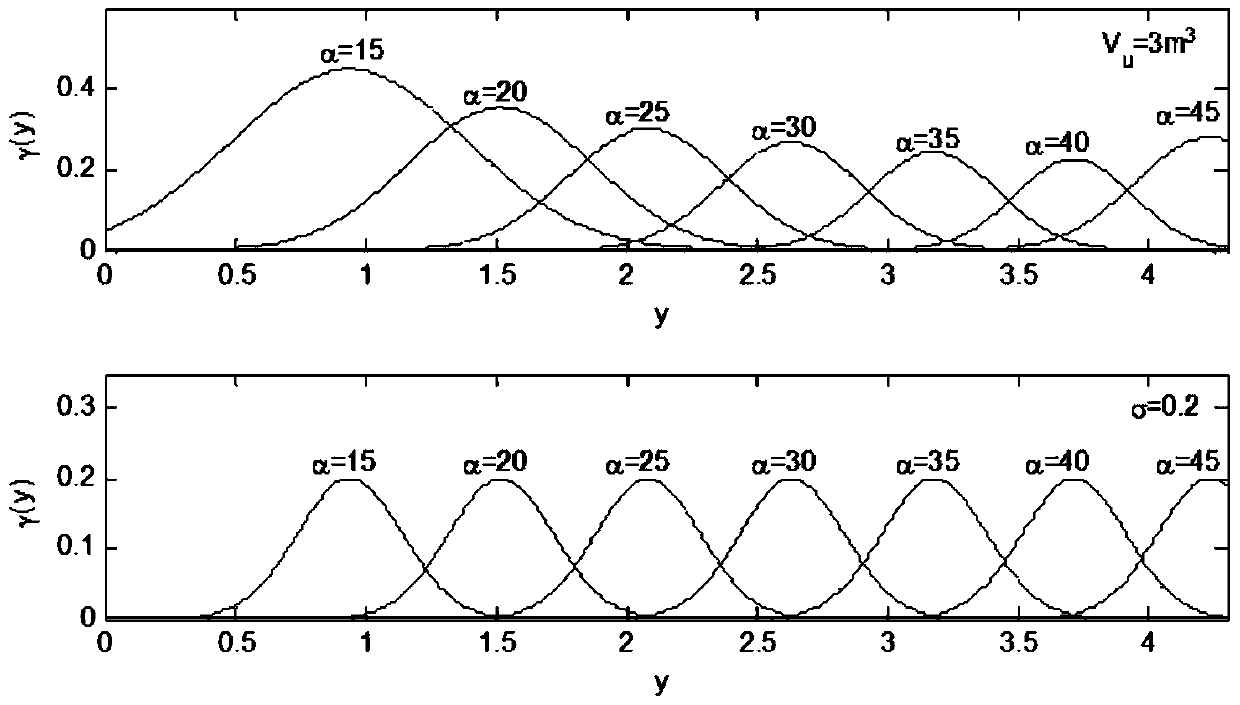

[0049] See Figure 1 to Figure 6 , the parameters of the blast furnace material distribution process are as follows:

[0050] Volume V of batch weight a

30m 3

The initial velocity of the material flow v 0

1.2m / s

Cloth time period T a

75s

The length H of the Y-shaped tube or the guide tube y

1.8m

Collision loss coefficient η

0.8

Chute length l o

4.0m

0.5

acceleration of gravity g

9.8m / s 2

Material line depth h

1.0m

Charge drop resistance F m

0.2mg

Chute rotation angle speed ω

0.84rad / s

The maximum inclination angle of the chute b

45 degree

The minimum inclination angle of the chute a

10 degrees

[0051] According to the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com