Full automatic machine for forming plaster mould box

A gypsum mold box, fully automatic technology, applied in ceramic molding machines, clay processing equipment, clay preparation equipment, etc., can solve the problems of low production efficiency and inability to meet the needs of large-scale construction, and achieve high production efficiency, light and simple equipment , the effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

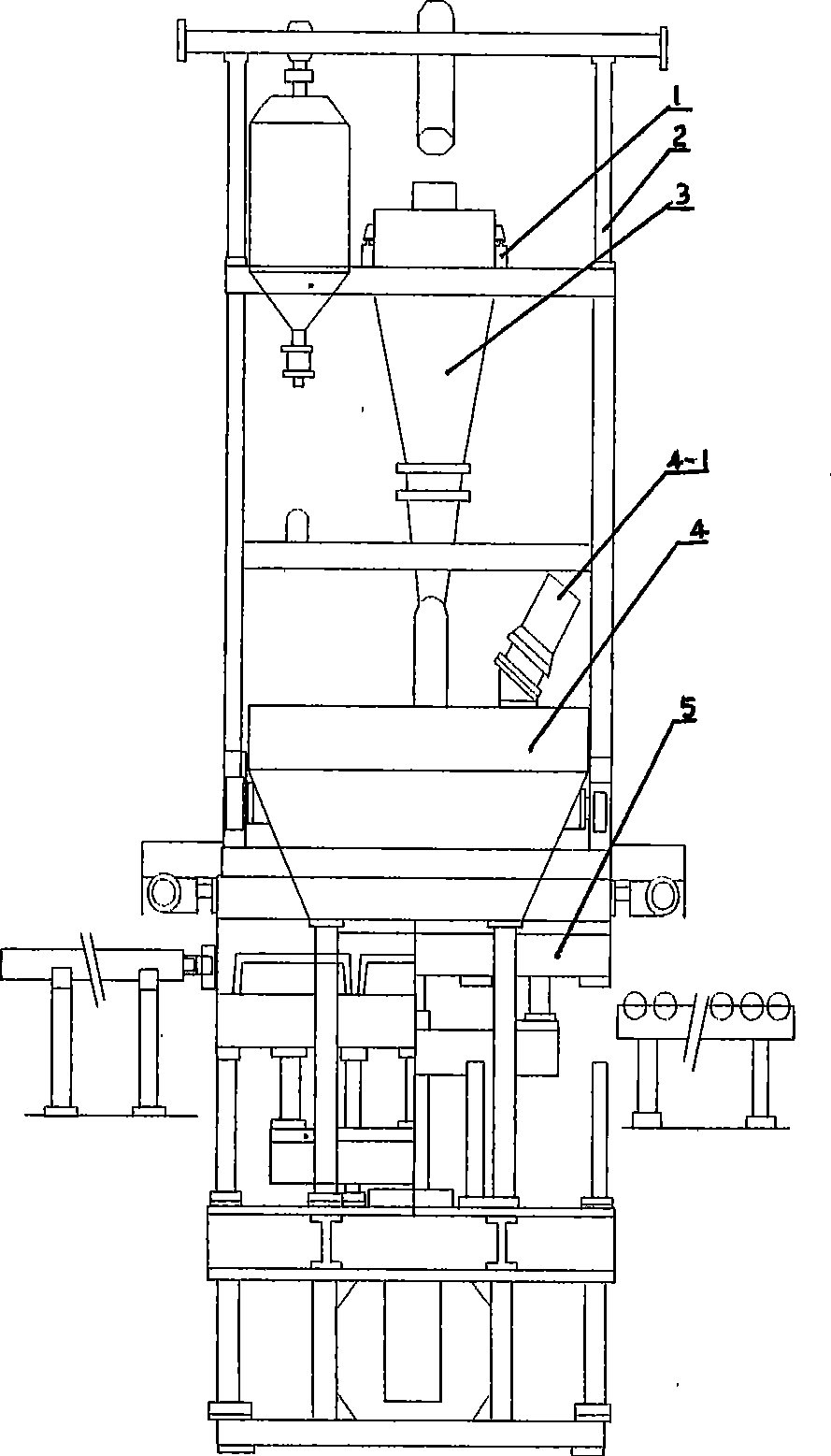

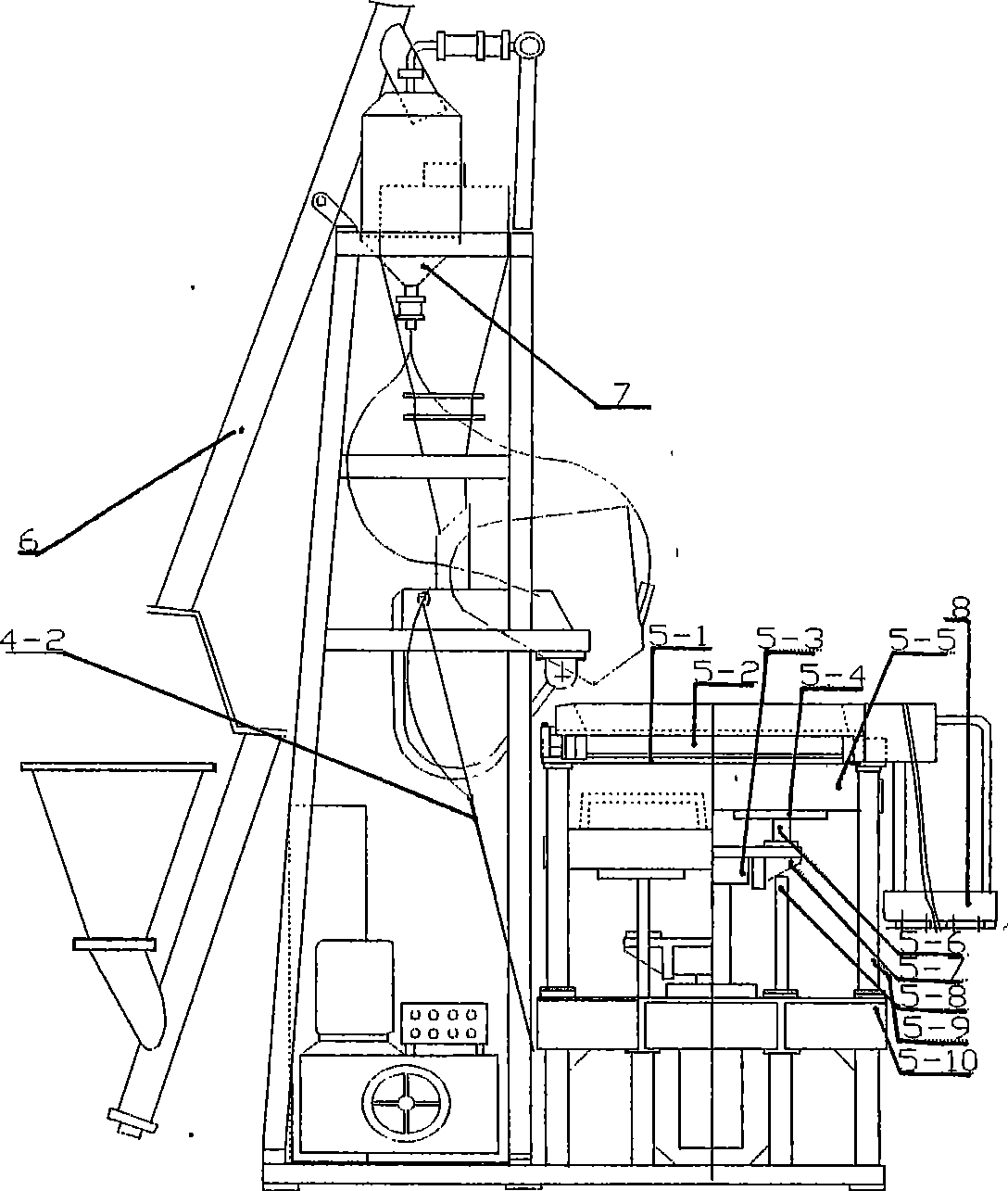

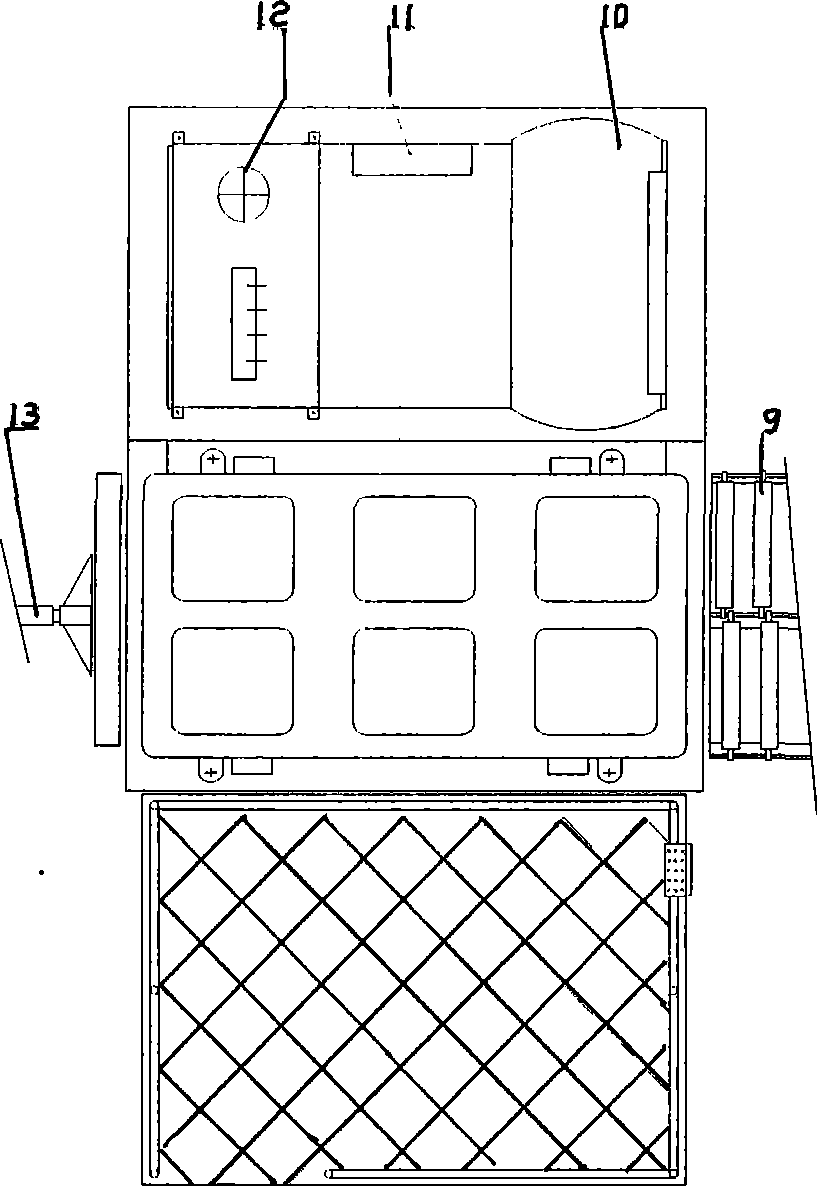

[0015] like figure 1 , figure 2 , image 3As shown, the present invention includes three sensors 1, a frame 2, a weighing bucket 3, a mixing turner 4, a six-cavity molding die 5, a screw feeder 6, a water metering bucket 7, a total operation console 8, a rolling Frame 9, pneumatic system air compressor 10, power distribution cabinet 11, hydraulic system 12, oil cylinder pusher 13. Three sensors 1 are screwed on the top of the frame 2 . The weighing bucket 3 is leveled on the three sensors 1, and the mixing turner 4 is connected to the motor 4-1 and the turning cylinder 4-2 respectively. The six-cavity forming mold 5 includes a die 5-1, a synchronous oil cylinder scraper beam 5-2, a lift 5-3, a punch 5-4, a stripping plate 5-5, a short connecting column 5-6, and a carriage beam 5- 7. The top column 5-8, the connecting column 5-9, and the oil cylinder sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com