A kind of manufacturing method of high-tower loss-controlled compound fertilizer

A technology for compound fertilizers and manufacturing methods, applied in the direction of urea compound fertilizers, inorganic fertilizers, fertilizer mixtures, etc., can solve the problems of low nutrient utilization rate, loss, and large loss of ordinary fertilizers, and facilitate mechanized fertilization, reduce ammonia loss, and produce low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

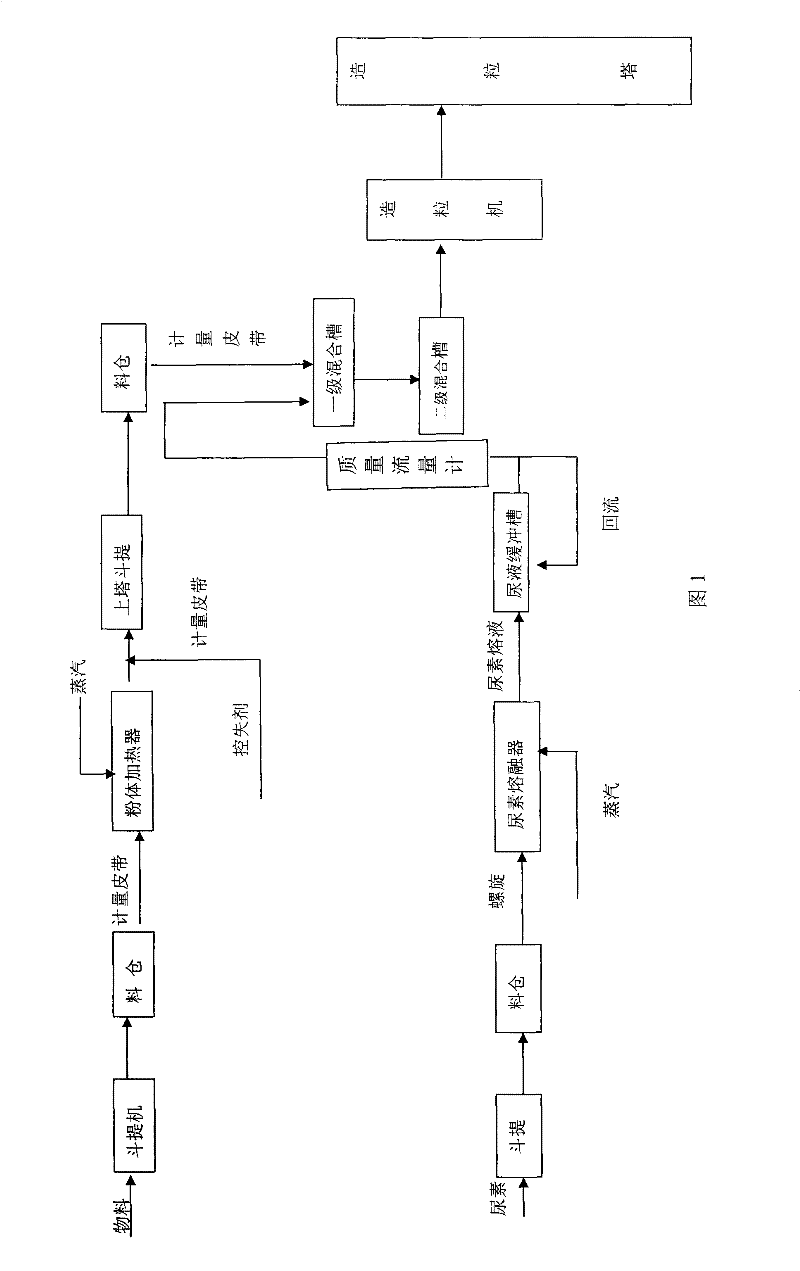

[0021] Embodiment 1: the manufacture method of high-tower loss-controlled compound fertilizer, concrete process operation steps are as follows:

[0022] 1) Pour granular urea into the receiving port, lift it to the buffer silo through the bucket elevator, and enter the urea melter through the feeding screw. After the urea melts, it flows into the urine buffer tank and is transported to the granulation process by the urea melting pump. The first-level mixing tank on the top of the tower, the urea melt entering the first-level mixing tank is 40 parts by weight.

[0023] 2) Monoammonium phosphate, potassium chloride, and calcium powder are respectively lifted to the silo via a bucket lift, and a weighing scale is designed at the bottom of the silo to measure 25 parts by weight of monoammonium phosphate, 13 parts by weight of potassium chloride, and 16 parts by weight of calcium powder. The powder heater is heated, and the heated material flows into the powder belt conveyor. At th...

Embodiment 2

[0025] Embodiment 2: operation step is the same as embodiment 1, and difference is that each raw material component is as follows:

[0026] 65 parts by weight of urea solution, 40 parts by weight of monoammonium phosphate, 20 parts by weight of potassium chloride, 20 parts by weight of calcium powder, and 8 parts by weight of nutrient loss control agent KS-3.

Embodiment 3

[0027] Embodiment 3: operation step is the same as embodiment 1, and difference is that each raw material component is as follows:

[0028] 50 parts by weight of urea solution, 30 parts by weight of calcium hydrogen phosphate, 25 parts by weight of potassium sulfate, 20 parts by weight of filler gypsum powder, and 7 parts by weight of chemical fertilizer nutrient loss control agent KS-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com