Compound type rotating axle seal

A rotating shaft, composite technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of low rigidity, unadjustable shaft seals, difficult to withstand high pressure for a long time, etc., to improve sealing and prolong service life. , the effect of increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

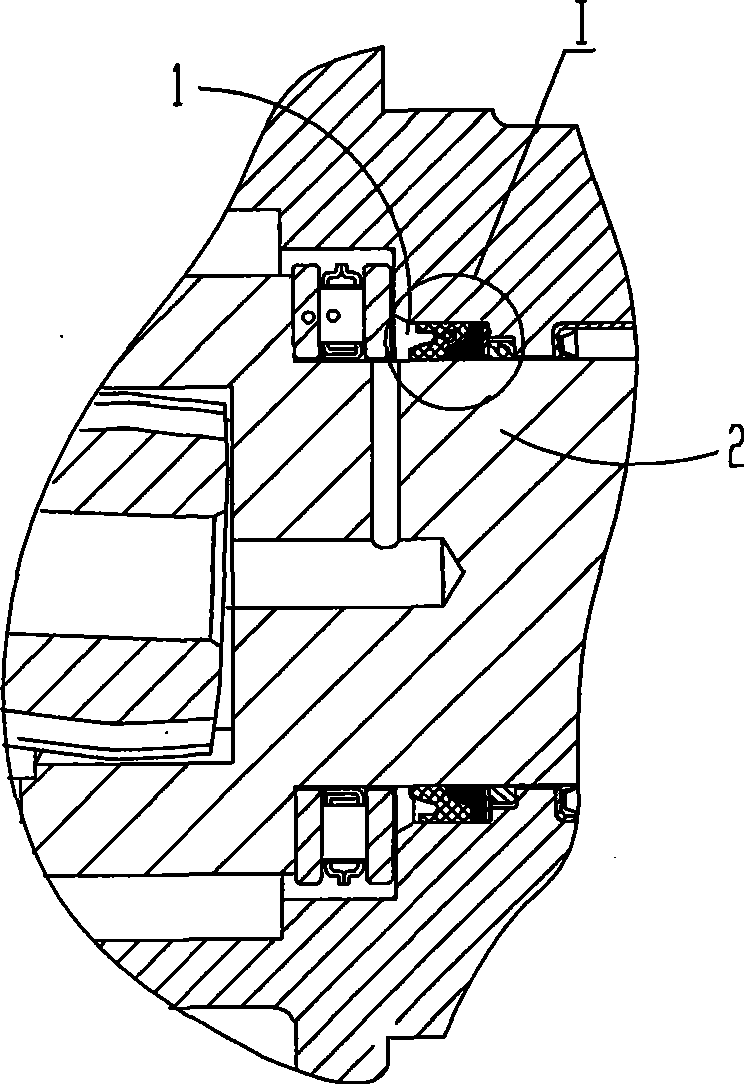

[0019] Such as figure 1 As shown, the composite rotating shaft of this embodiment is sealed and mounted between the housing hole 1 and the rotating shaft 2 of the high-speed distribution cycloid hydraulic motor.

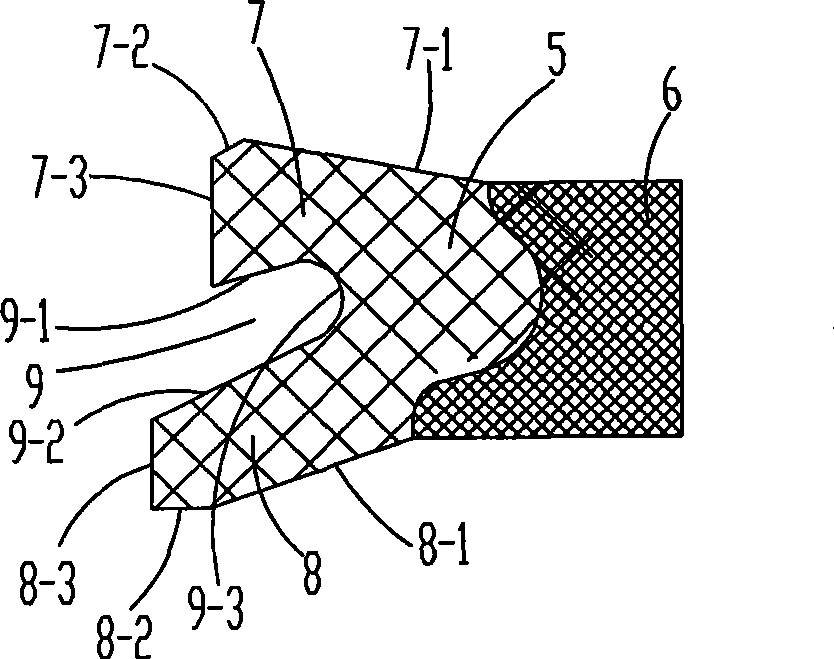

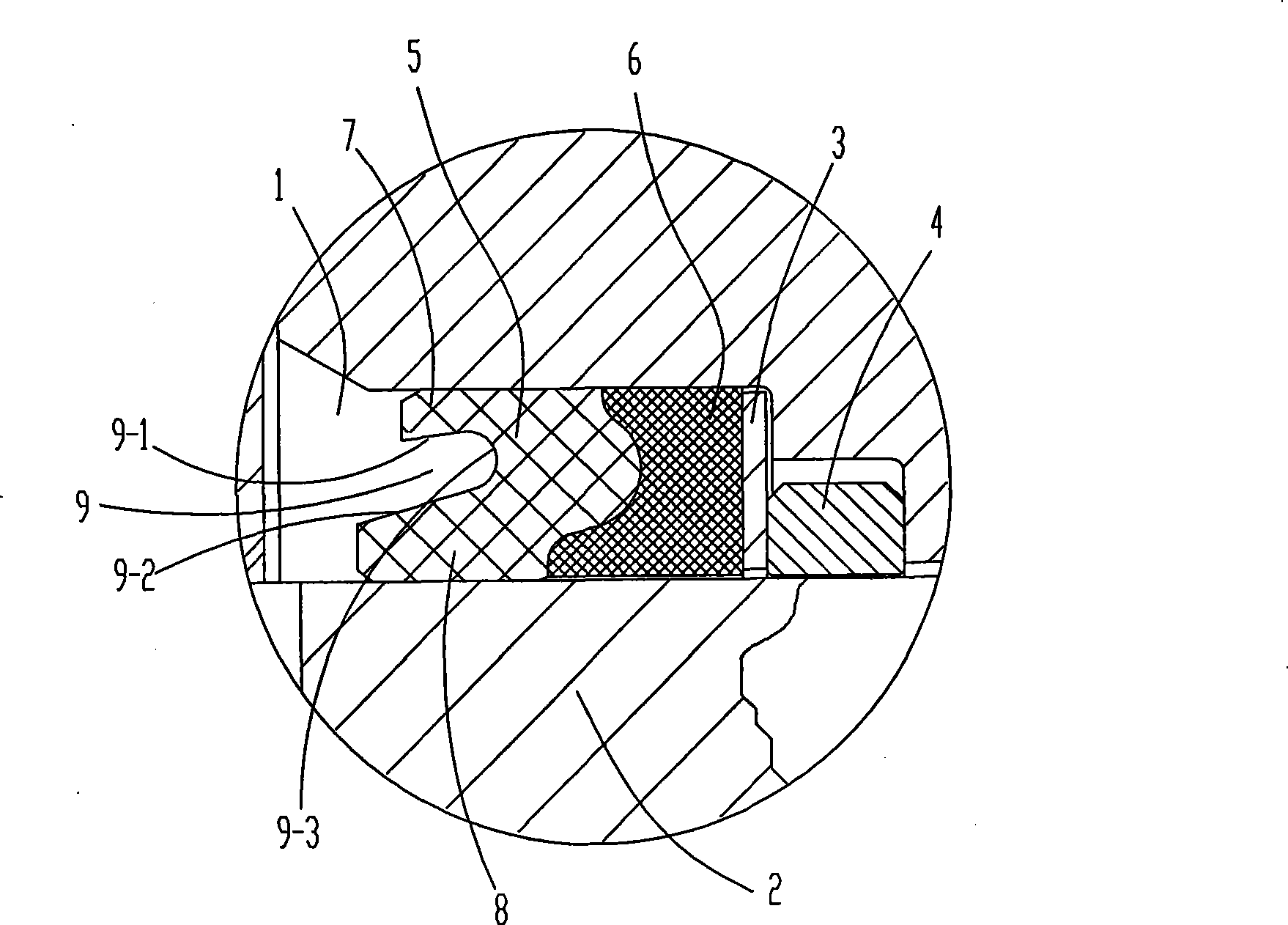

[0020] Such as figure 2 As shown, the composite rotary shaft seal includes a composite sealing body, a spacer ring 3 and a movable retaining ring 4 which are sequentially assembled together in the axial direction. The composite sealing body is composed of a rubber ring body 5 and a skeleton ring body 6 whose end faces are closely attached to each other, and the rubber ring body 5 forms an interference fit with the housing hole 1 and the rotating shaft 2 respectively. The rubber ring body 5 is formed with a lip structure facing the high-pressure medium in the axial direction. The lip structure is composed of an upper lip 7 abutting against the housing hole 1 , a lower lip 8 abutting against the rotating shaft 2 , and a notch 9 connecting the upper lip 7 and the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com