Ultra-high pressure explosion-proof gas tank

A gas storage tank and ultra-high pressure technology, applied in fixed capacity gas storage tanks, pressure vessels, gas/liquid distribution and storage, etc., can solve the problems of poor explosion-proof performance and heavy weight of gas storage tanks, and achieve safe use, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

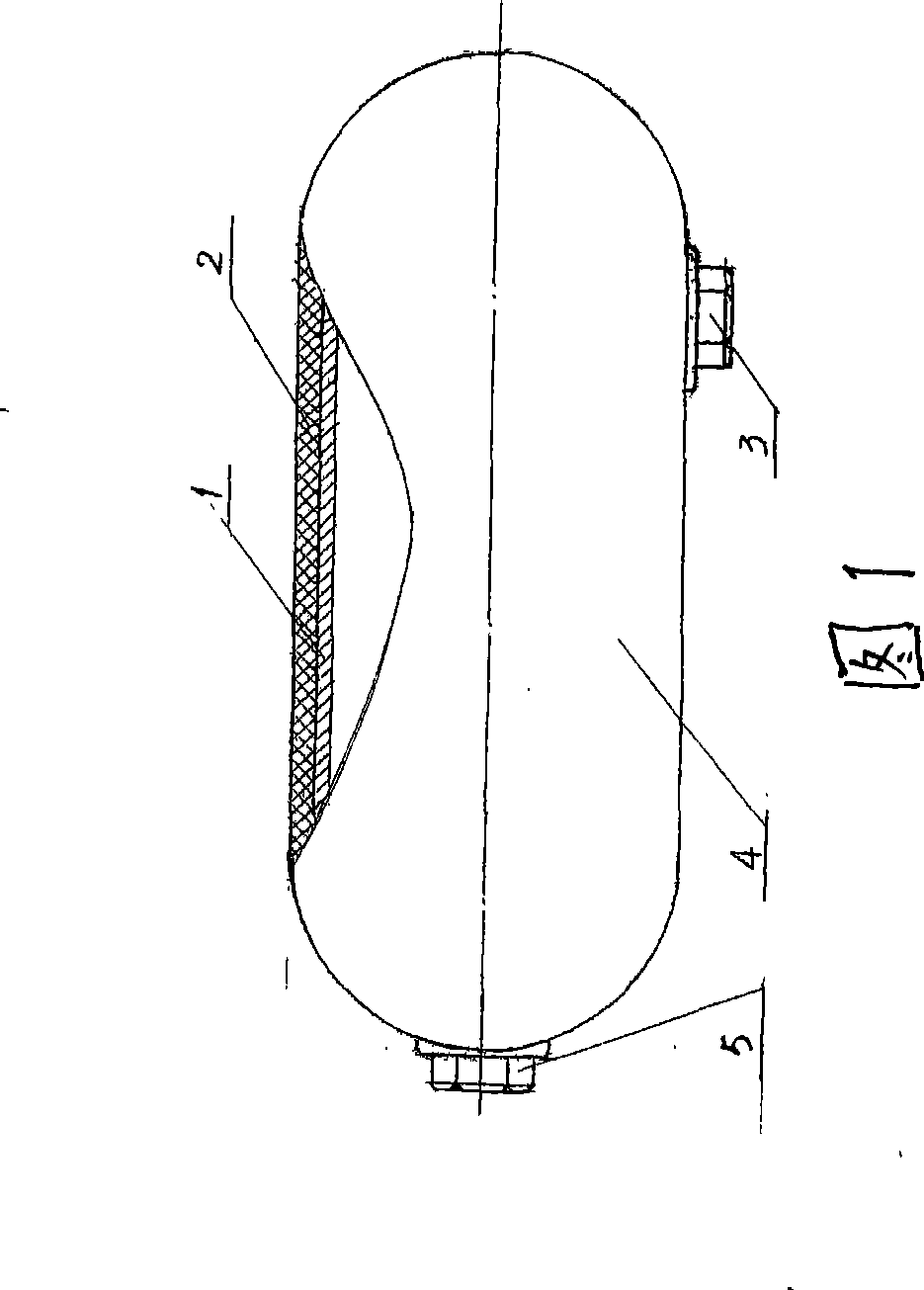

[0009] As shown in Figure 1, an ultra-high pressure explosion-proof gas storage tank has an inner tank 1 and an outer shell 2. The cylinder body of the inner tank 1 is closely provided with an air inlet port 3, and the other end is closely provided with a release port 5. The inner tank 1 Made of ultra-thin stainless steel, the shell 2 is made of nylon carbon fiber reciprocatingly misplaced and wound on the surface of the inner tank 1, and the surface of the shell 2 is provided with a protective layer 4 coated with nylon resin.

[0010] When working together with the aerodynamic energy generating device, when the stored high-pressure gas encounters a special situation or exceeds the withstand pressure, the inner liner 1 and the outer shell 2 of the storage tank are torn into openings at the same time, and the gas in the tank is rushed out from the tearing opening. There will be no explosive flying objects when the air storage tank is deformed, but only burst and leak gas, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com