Ash cleaning and descaling robot for heat medium stove

A technology of dust removal and robot, which is applied in the direction of lighting and heating equipment, can solve the problems of not having the magnetic adsorption function of the pipe wall, and achieve the effect of automatic cleaning, avoiding environmental pollution, and reducing physical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structure of the dust-cleaning and descaling robot for the heat medium furnace of the present invention will be described in detail below in conjunction with the accompanying drawings.

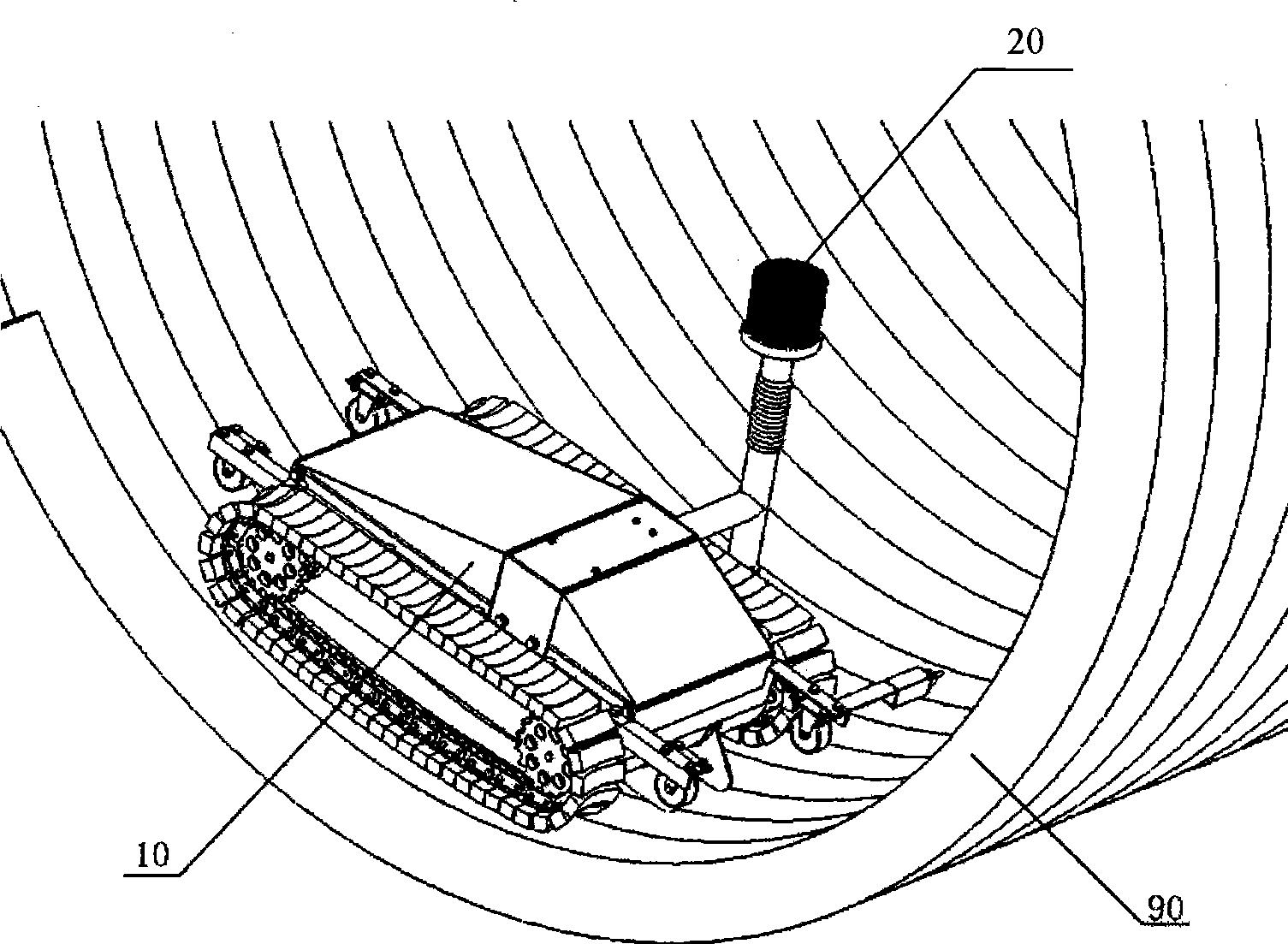

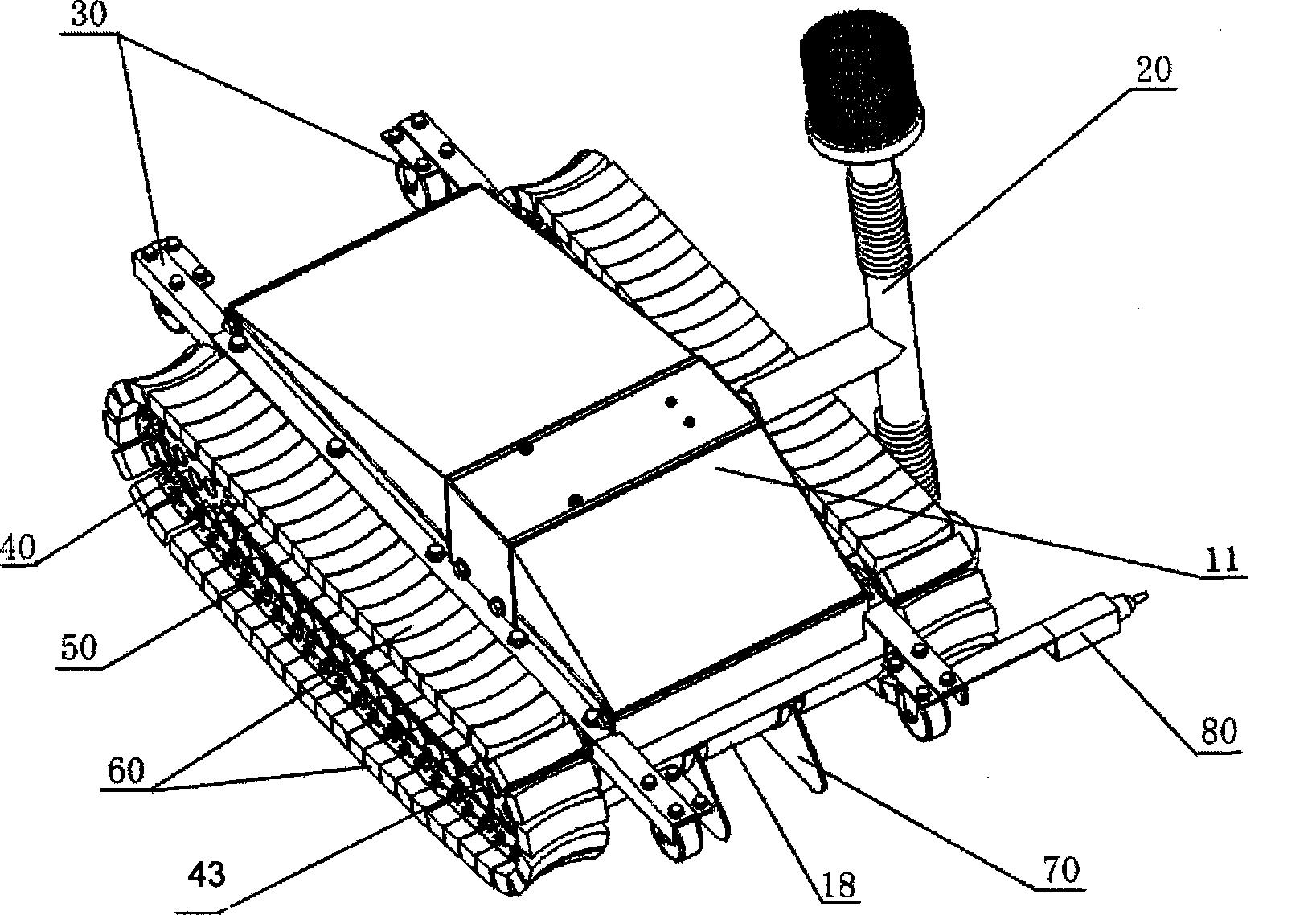

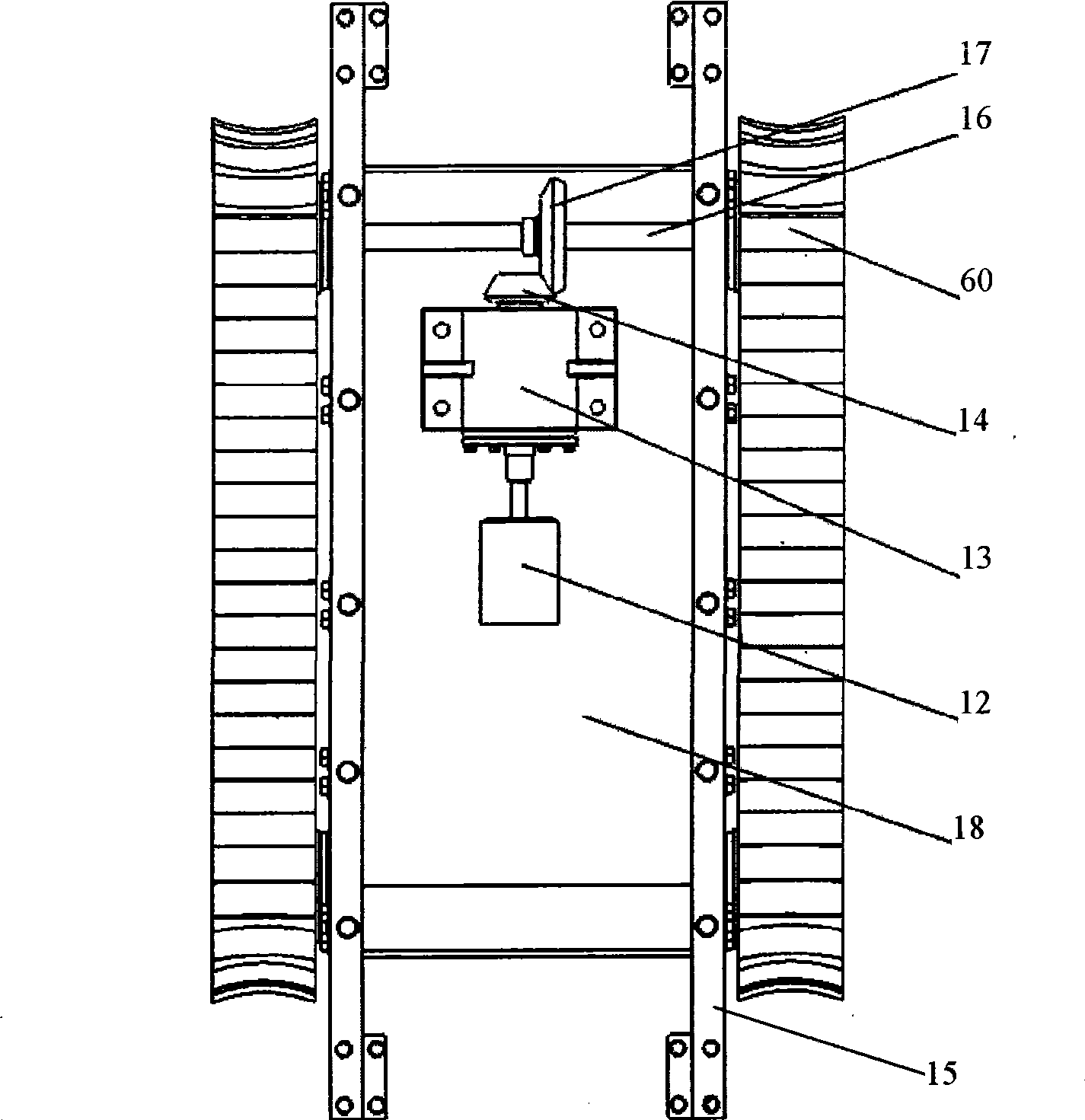

[0028] see figure 1 , shown in the figure is the cleaning and descaling robot of the present invention adsorbed on the inner wall of the heat medium furnace. Wherein 10 is the robot body, 90 is the spiral coil pipe of the inner wall of the heat medium furnace, and the spiral coil pipe 90 is made of seamless carbon steel pipe welding, and the whole body of heater is a horizontal cylindrical body. As shown in the figure, the robot body 10 is adsorbed on the inner wall of the heat medium furnace, crawls along the path of the spiral coil 90, and returns along the original path after crawling along the spiral coil 90 to the bottom of the furnace until returning to the furnace mouth. During the walking process, the dust-cleaning and descaling brush 20 rubs against the furnace wall by rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com