Engine net torque detection fixture

A torque detection and engine technology, applied in the field of tooling and fixtures, can solve the problems of engine power, torque reduction, increased labor intensity of workers, low assembly efficiency, etc., to achieve the effect of easy implementation, guaranteeing assembly quality, and improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

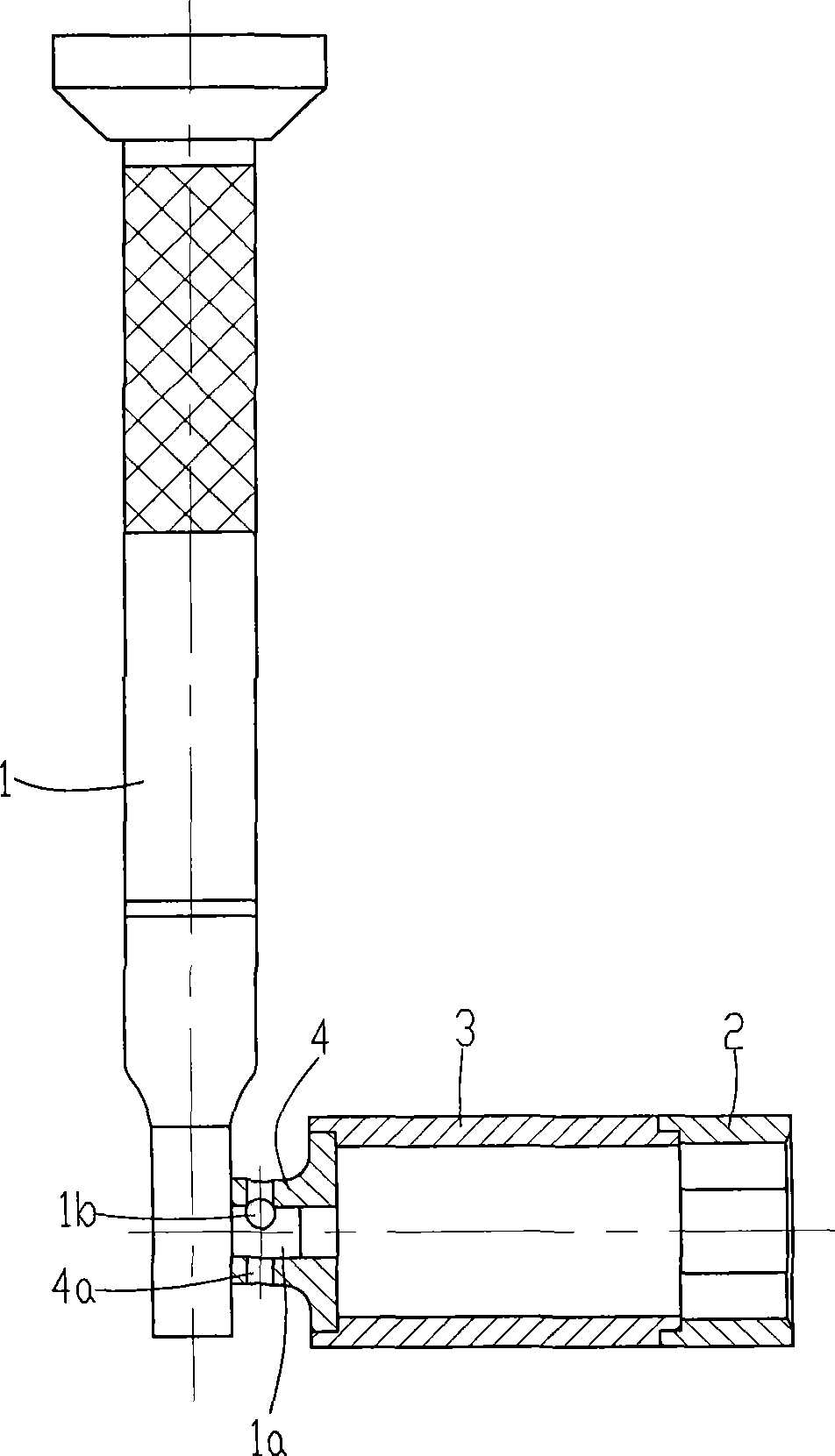

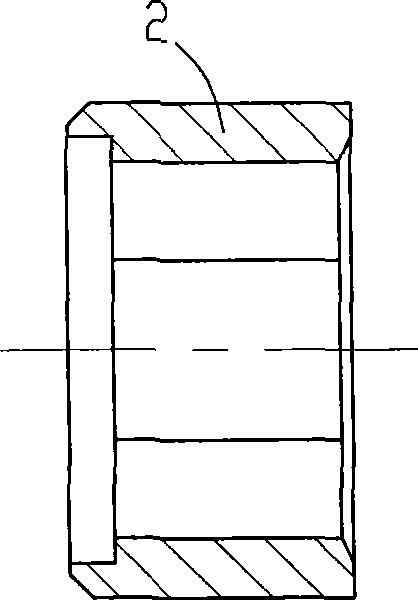

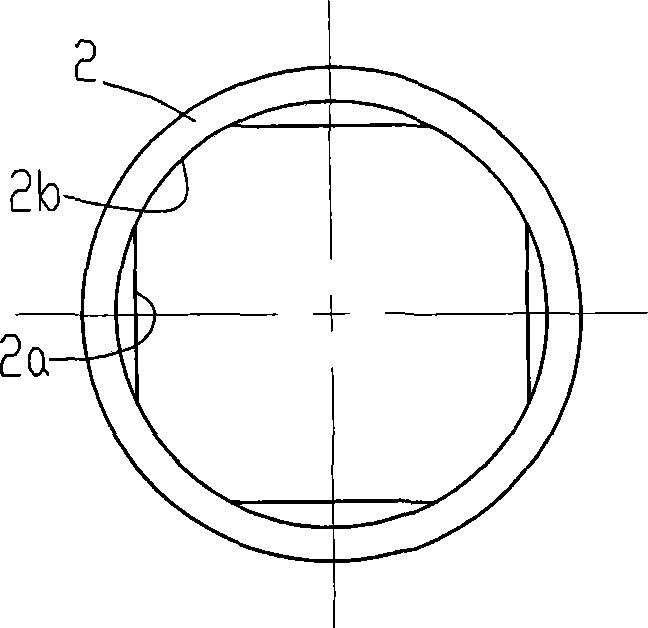

[0017] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention is composed of a constant value torque wrench 1 and a socket, wherein the socket includes three sections of the front section 2 of the socket, the middle section 3 of the socket and the rear section 4 of the socket, all of which are through pipe structures. The front section 2 of the socket is located at the front side of the middle section 3 of the socket, and the front section 2 of the socket and the middle section 3 of the socket are connected and fixed by welding, and the contact surface between the two is stepped. The inner wall of the front section 2 of the socket is adapted to the oil pump installation stage 5a on the engine crankshaft 5, that is, the front end of the inner wall of the front section 2 of the socket is conical, the rear end is circular, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com