Capacitive MEMS sensor device

A sensor device, capacitive technology, applied in the direction of sensors, sensor types, electrostatic sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the following text, a MEMS microphone is generally described as an exemplary embodiment of the invention. However, the invention is generally also applicable to all capacitive MEMS sensors, not limited to MEMS microphones.

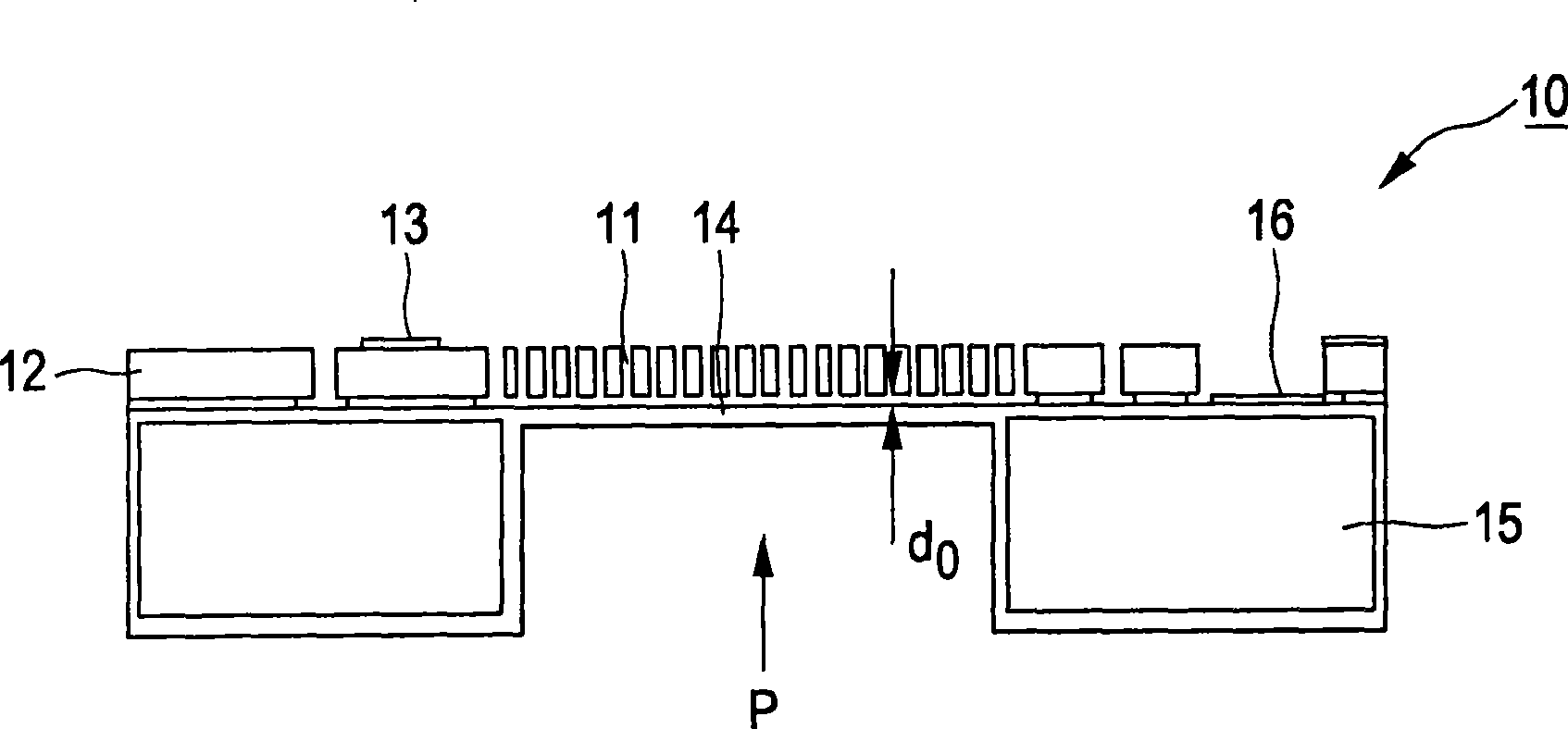

[0043] figure 1 The principle of the capacitive MEMS sensor 10 is shown, and the capacitive MEMS sensor is used to convert the mechanical quantity P (such as the incident sound pressure) into the change of the capacitance value, and the change of the capacitance value is obtained by changing the capacitance between the capacitor plates 11, 14. distance is realized. The capacitor includes two parallel plates, specifically: a rigid plate 11 fixed on a first frame 12 and connected to an electrical contact assembly 13; Forms a rigid unit, but is electrically isolated from the first frame) and is connected to the other plate 14 (in particular the membrane) of the electrical contact assembly 16 . The latter plate 14 moves or bends under the influenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com