Locking structure of discharging door of a hard ice cream machine and the application thereof

A technology of locking structure and hard ice cream, applied in application, frozen desserts, food science, etc., can solve the problems of material liquid exposure, poor sealing, inconvenient cylinder cleaning, etc., to achieve uniform locking force, coordinated appearance, and sealing good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

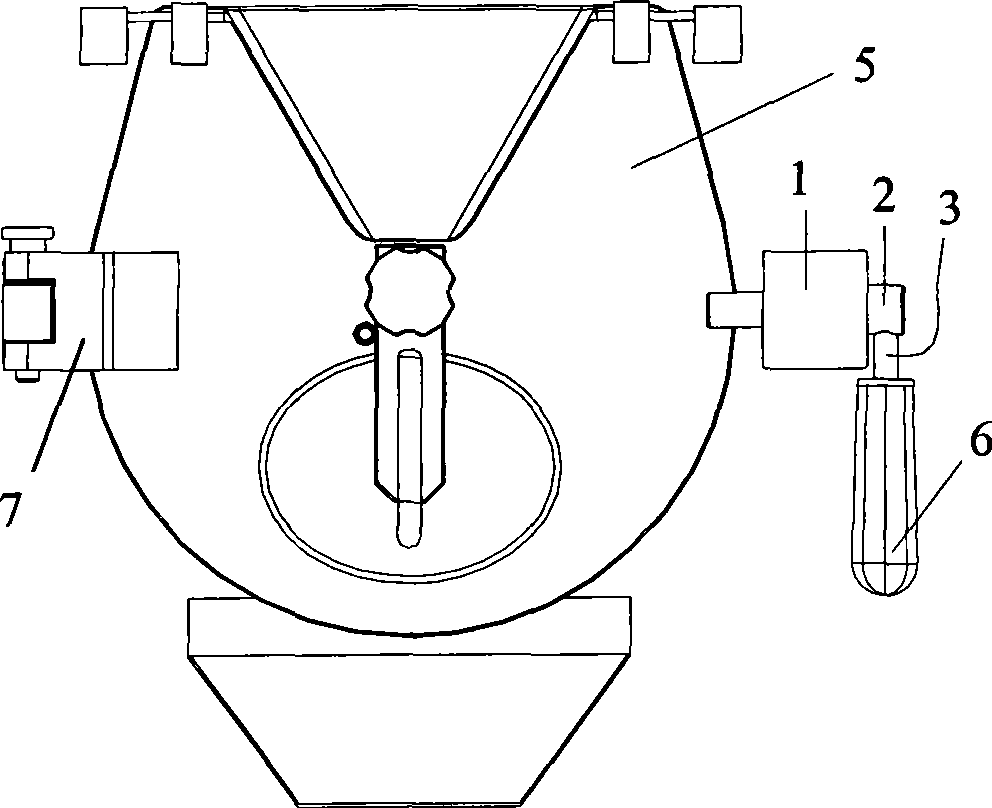

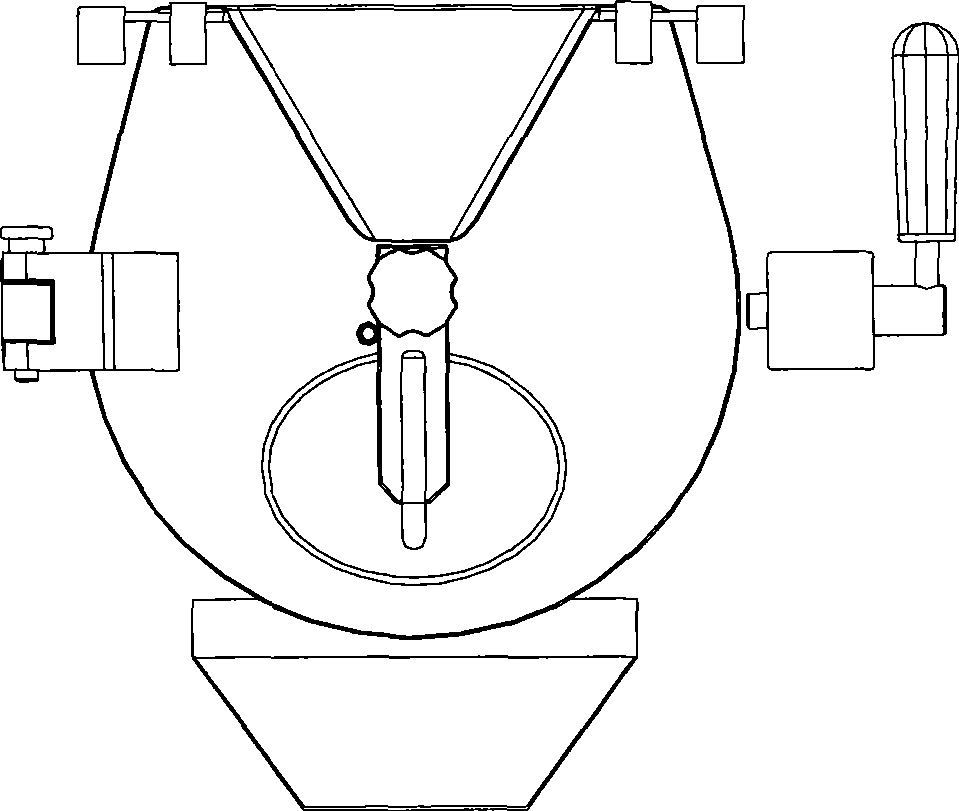

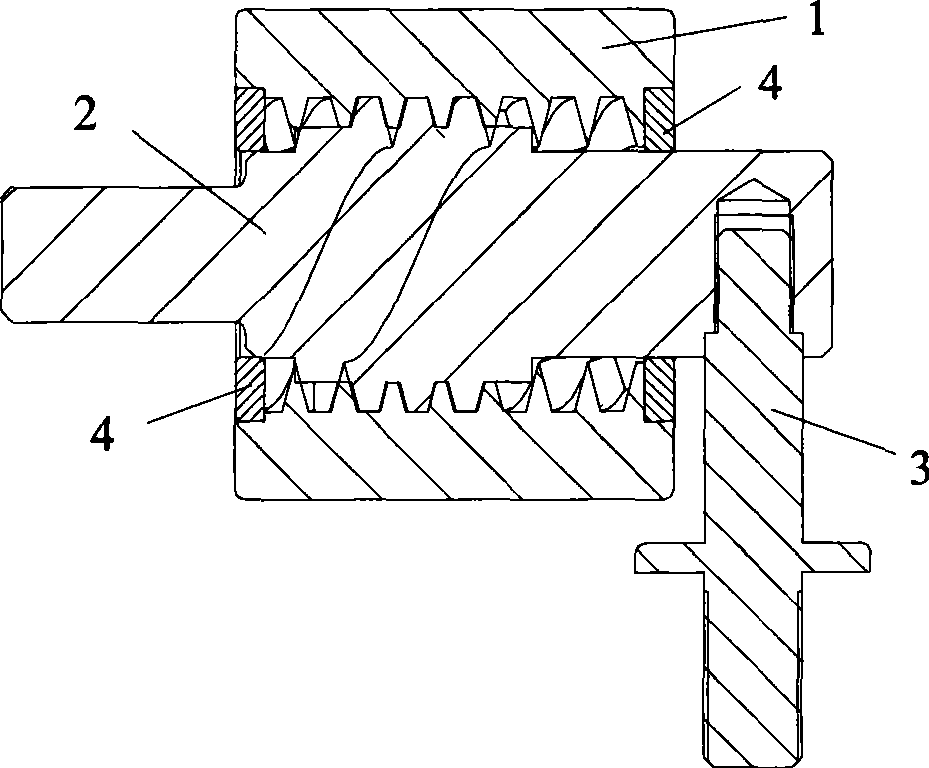

[0022] see Figure 1 to Figure 8 ,in, figure 1 and figure 2 It is a structural schematic diagram of the present invention in the locking / releasing state respectively, image 3 It is a schematic diagram of the internal structure of the locking structure. As shown in the figure, the left side of the discharge door 5 of the hard ice cream machine is movably fixed by a hinge plate structure 7, and a locking structure is fixedly installed on the right side of the discharge door 5 of the hard ice cream machine, and the locking structure further includes Handle rotating shaft seat 1, rotating shaft A2, rotating shaft B3, copper bushing 4 and handle 6, wherein the handle rotating shaft seat 1 is fixedly installed on the hard ice cream machine and is close to the right side of the discharge door 5; the rotating shaft A2 extends from the handle rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com