Tobacco online expansion and treatment device, equipment system and processing method thereof

A technology of expansion treatment and shredded tobacco, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of increased crushing rate of shredded tobacco material, reduction of crushing rate, and difficulty in continuous discharge, so as to achieve low-temperature fragrance preservation, The effect of reducing the sedimentation velocity and lowering the working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

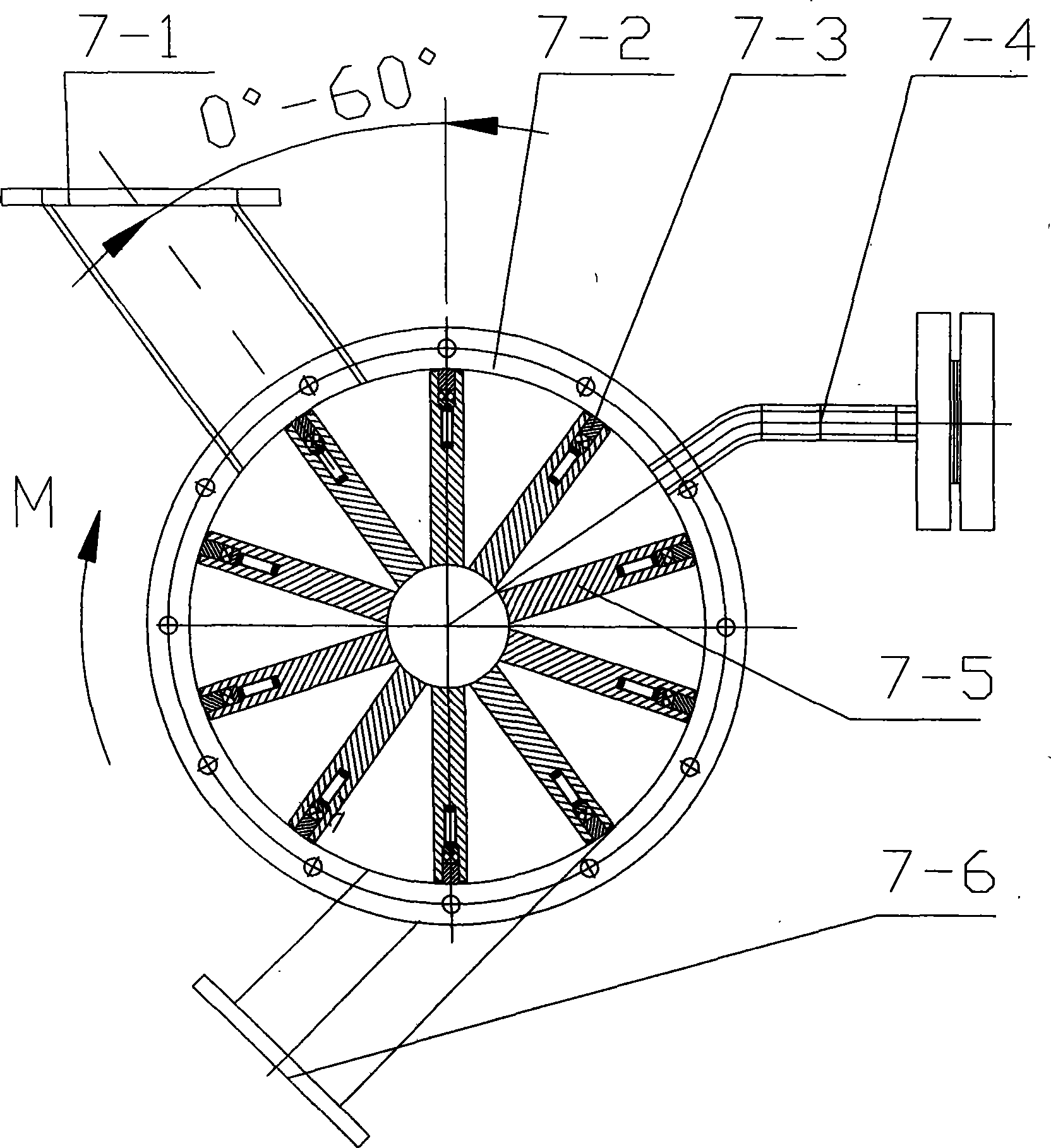

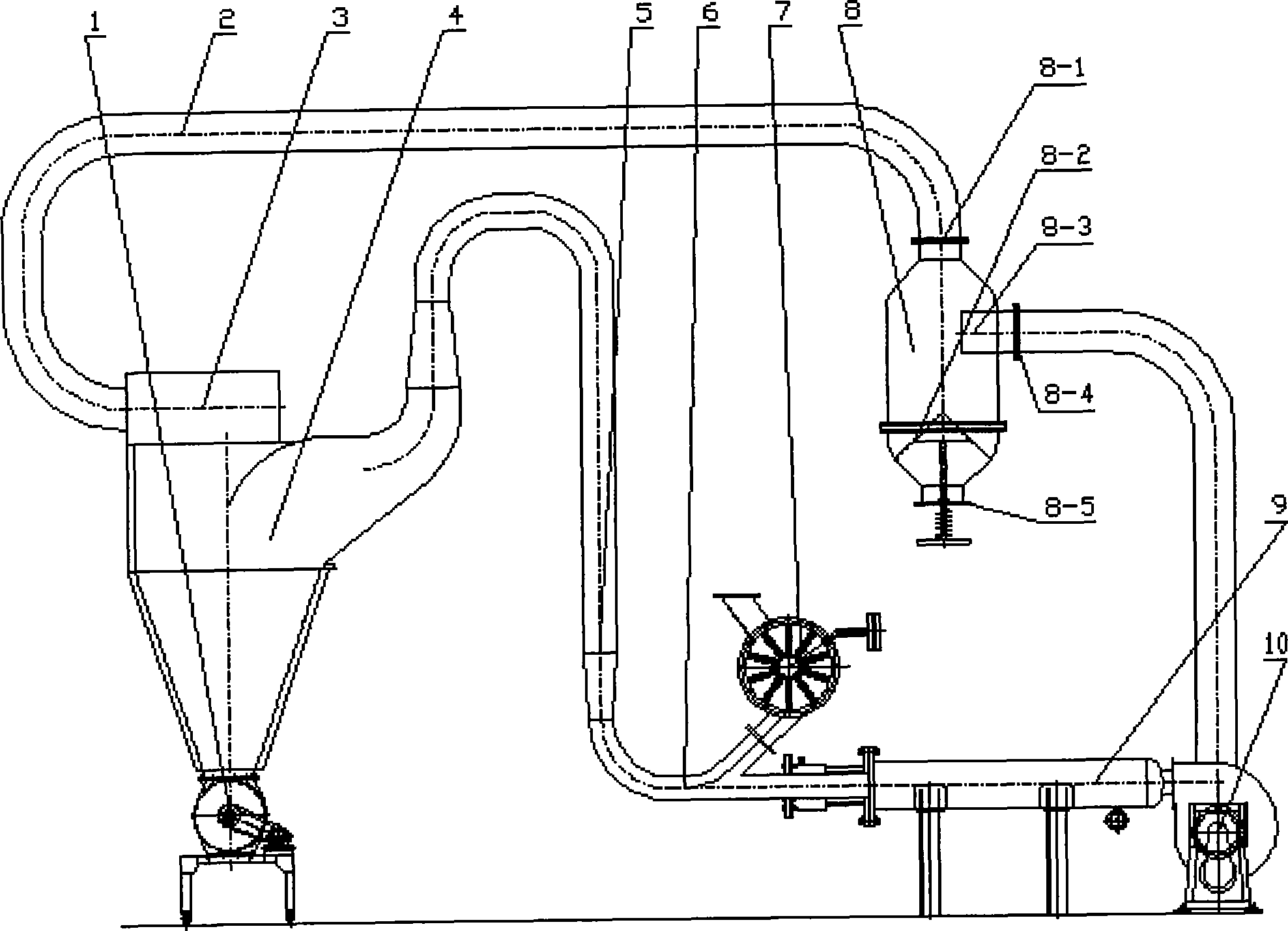

[0036] Such as figure 1 As shown, the on-line expansion processing device for shredded tobacco is an expansion air lock 7 . As a preferred example, the expansion airlock 7 includes a feed port 7-1, a housing 7-2, an air inlet 7-4, a rotating web 7-5, and a discharge port 7-6; the feed port 7- The central line of 1 and the central axis of the expansion air lock 7 form an angle of 30°-45°; the discharge port 7-6 is biased towards the direction of the feed port; the top of the rotating web 7-5 is provided with a movable sealing sheet 7-3; The gas port 7-4 communicates with the overpressure hot gas source.

[0037] During expansion air lock 7 work, the direction of rotation of its rotating spoke plate 7-5 is as figure 1 In the direction indicated by the "M" arrow in the center, to ensure that during the rotation of the airlock rotor, at least one or more spoke plates are always maintained between the inlet and the inlet, and between the inlet and the outlet. Realize the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com