Monoblock cast type short stroke extruder compact type framework

An integral casting and short-stroke technology, which is applied in the frame field of aluminum and aluminum alloy extrusion machines, can solve the problems of long installation and debugging time, heavy maintenance workload, heavy processing workload, etc., achieve compact structure and reduce equipment cost , the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

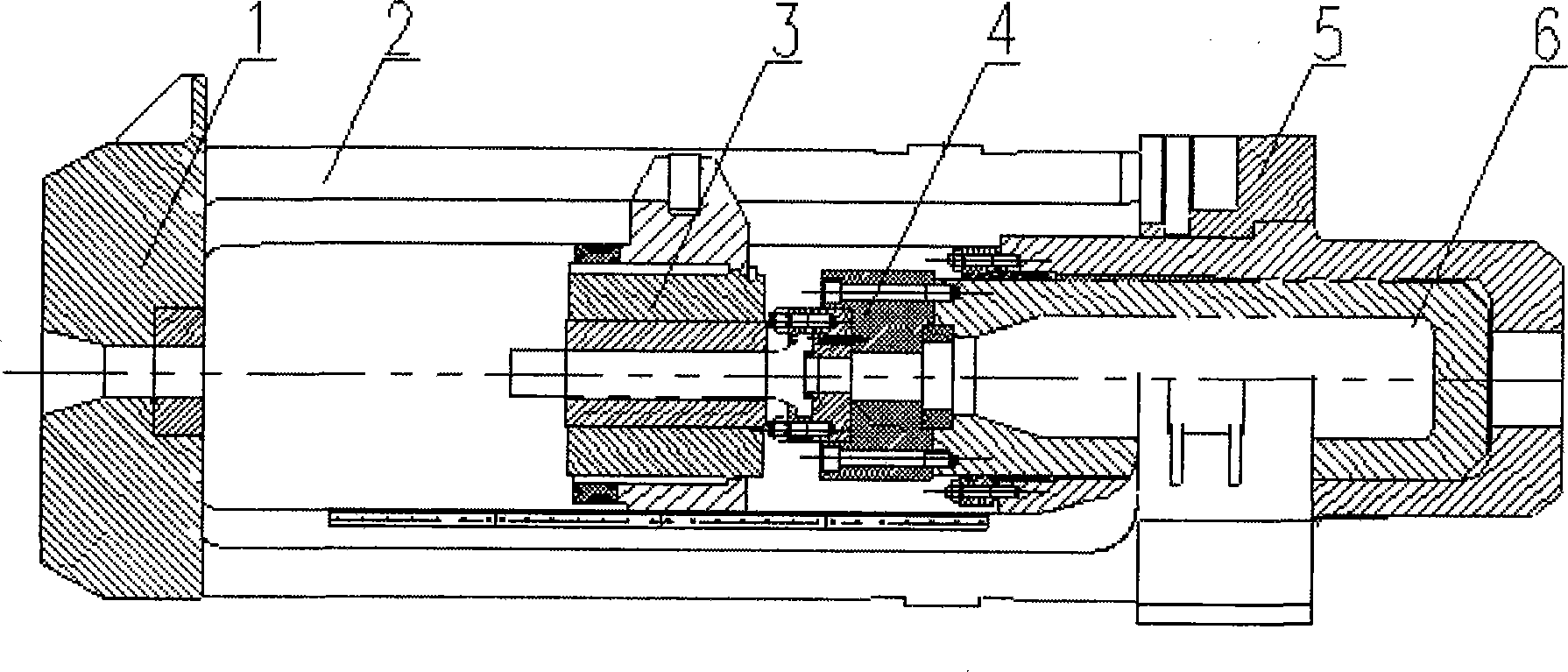

[0009] like figure 1 As shown, the compact frame of the integral casting short-stroke extruder at least includes a front beam part 1, a tie rod part 2, and a rear beam part 5. The rear beam part 5 fixes the main cylinder 6, and the movable crossbeam 4 is connected to the main cylinder 6. The extrusion cylinder 3 is connected to the main cylinder 6. The upper and lower pull rod parts 2 are slidingly connected, and the front beam part 1, the tie rod part 2 and the rear beam part 5 form an integral frame part by casting, and the rest of the extrusion machine, such as the extrusion cylinder 3 and the main cylinder of the extrusion machine, etc. Installed inside it to realize the extrusion function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com