Single upper seal sand blasting perforation fracturing technology

A sandblasting, perforating and fracturing technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc. to achieve the effect of not easy sticking and easy sand washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

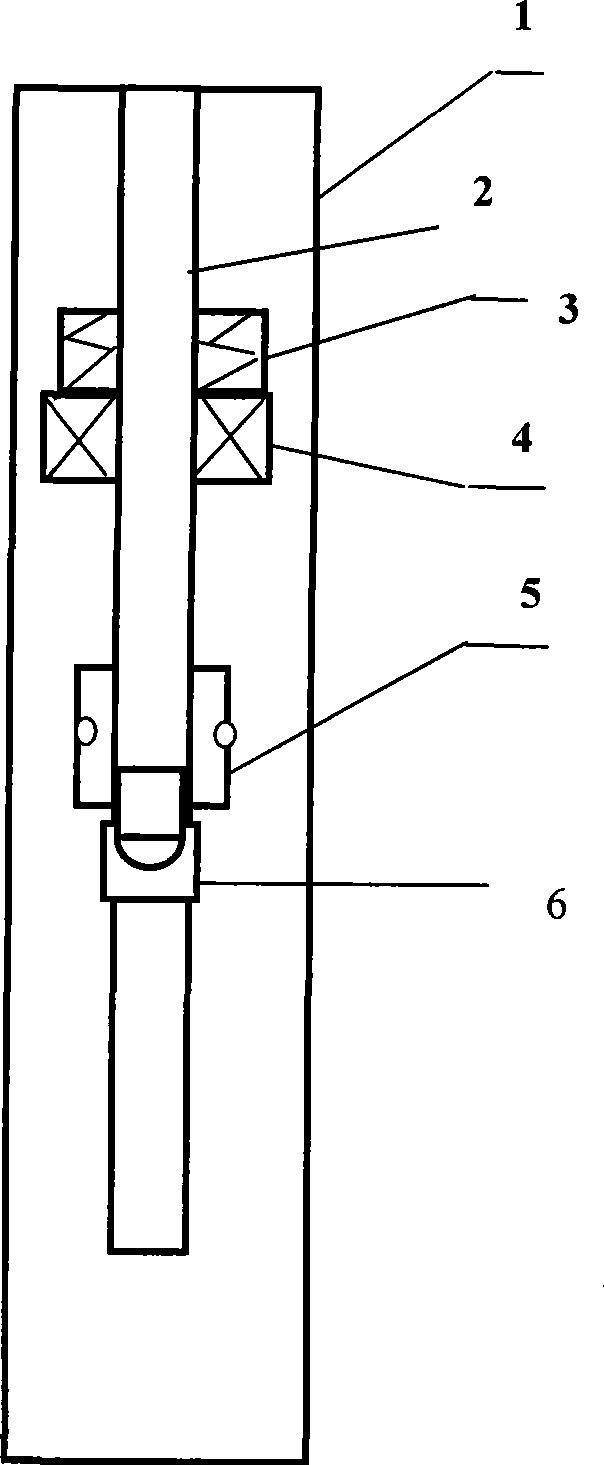

[0031] Example 1 as figure 1 As shown, the construction string connected with the hydraulic anchor 3, the mechanically set packer 4, the hydraulic injector 5, the injectable sand fluid backflow protector 6, and the oil pipe 2 are lowered into the casing from top to bottom. In the pipe 1, the water jet 5 should be aimed at the layer to be constructed;

[0032] 1) Press figure 1 According to the connection method shown in , the construction pipe is run down to the oil and gas layer to be constructed;

[0033] 2) Inject from tubing 2 and return from casing 1 to perform positive circulation flushing;

[0034] 3) After the positive cycle flushing is completed, put the injectable sand liquid backflow protector 6 from the wellhead, and send it to the lower part of the hydraulic injector with a certain displacement of liquid flow, and let it push the lower part of the hydraulic injector 5 It is completely blocked, and there is no puncture leakage; the pumped liquid can only be spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com