Above-water drilling operation platform

A drilling operation and console technology, which is applied to ship components, anchoring arrangements, transportation and packaging, etc., can solve the problems of inconvenient operation, long construction period, and easy drill jamming, so as to achieve not easy shaking, convenient operation, and short construction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

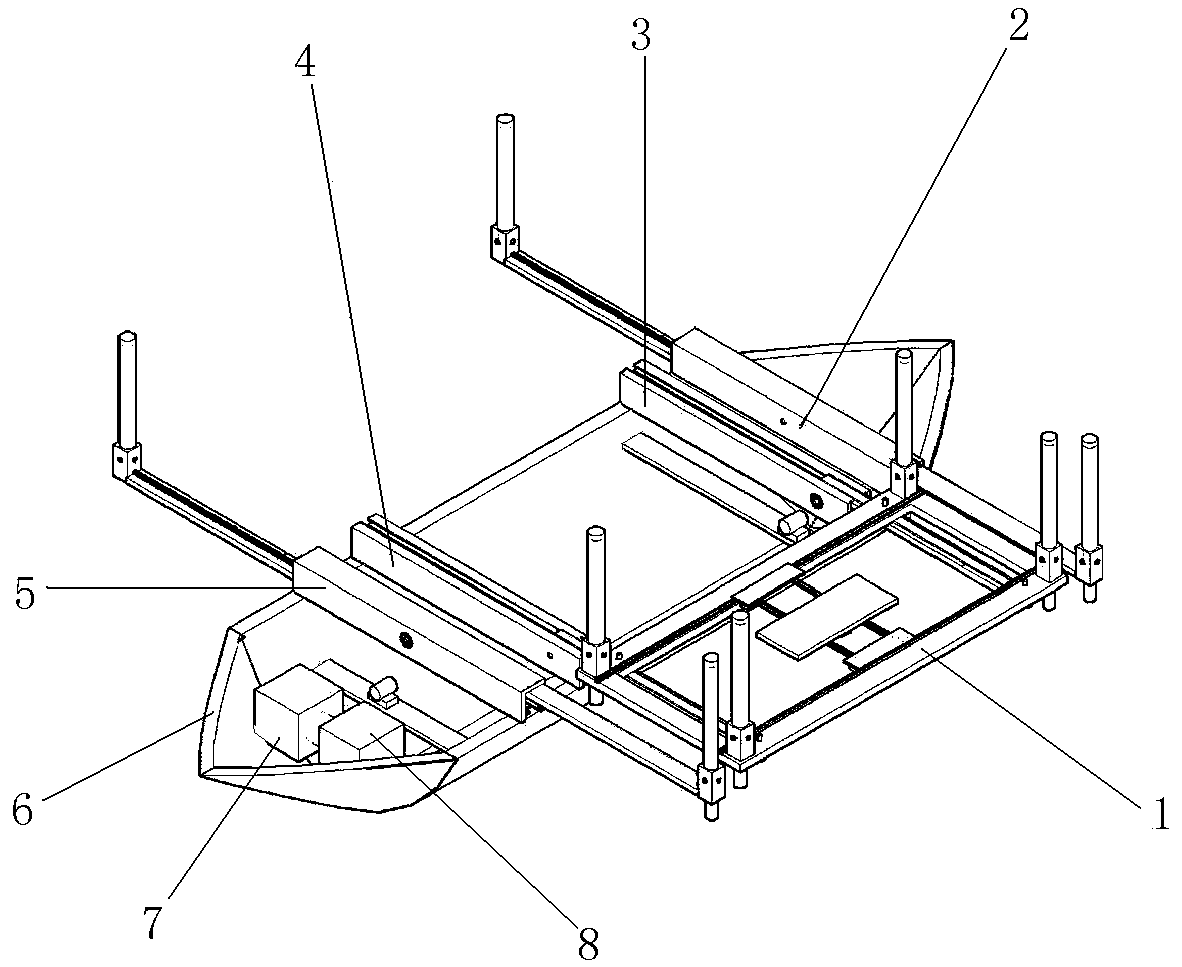

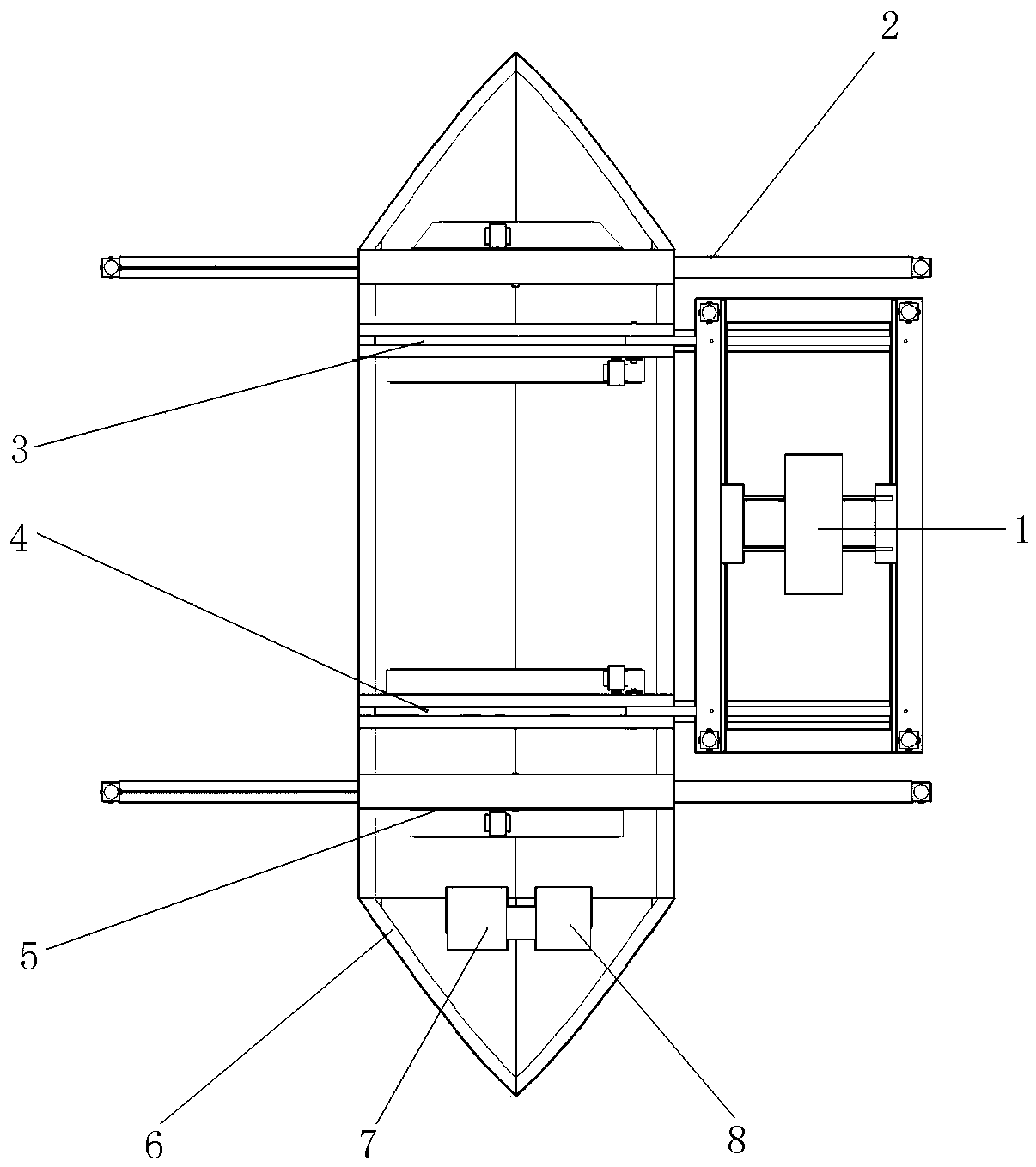

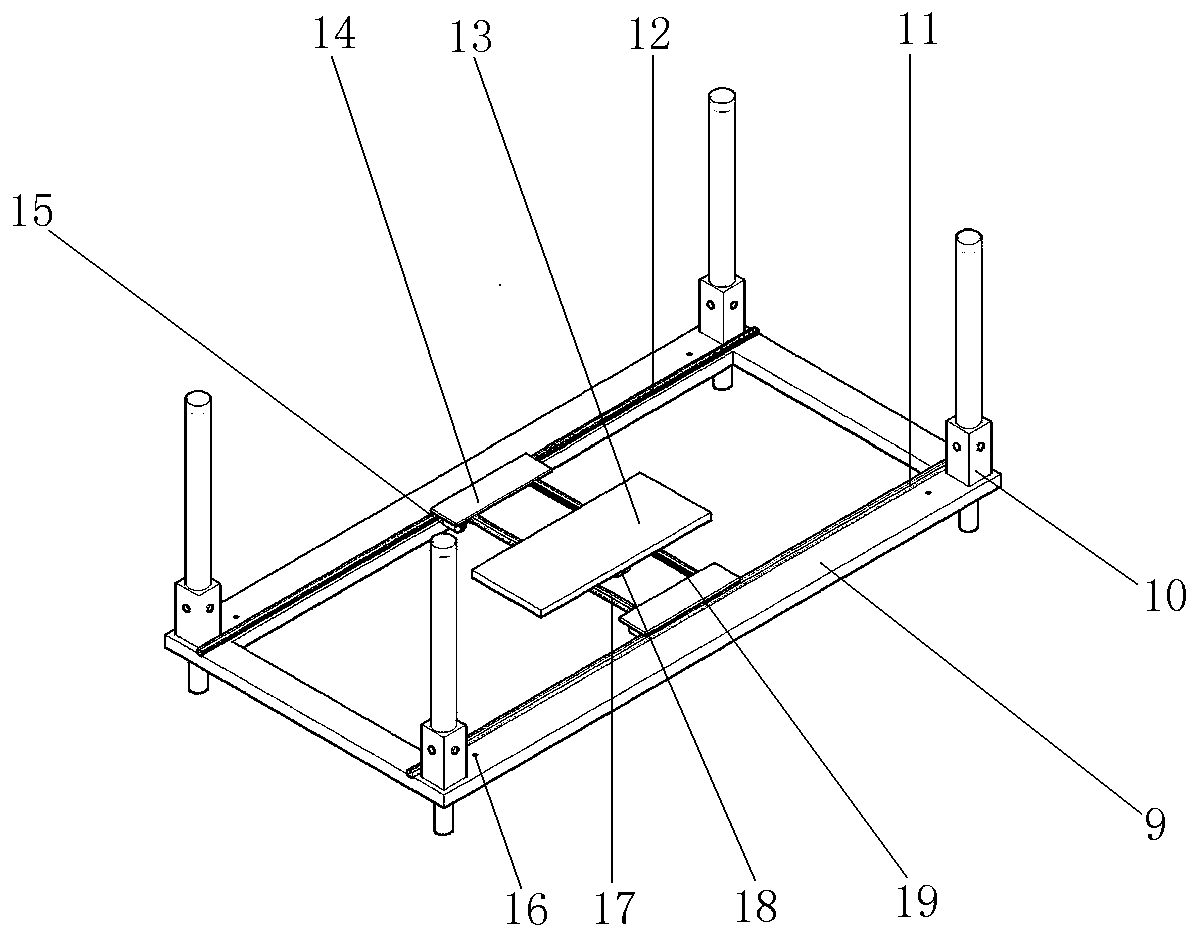

[0035] Such as Figure 1-19As shown, a water drilling operation platform of the present invention includes a platform 1, a ship 6, an engine 7, a hydraulic assembly and a generator 8, and is characterized in that: the platform 1 is respectively connected to the retraction mechanism A3, the retraction mechanism B4, and the retraction mechanism A3 1. The retraction mechanism B4 is installed on the two ends of the ship 6. The two ends of the ship 6, the retraction mechanism A3, and the outer sides of the retraction mechanism B4 are respectively equipped with a support mechanism A2 and a support mechanism B5, wherein: the platform 1 is composed of a frame 9, a support pump A10, and a walking track A11, walking track B12, console A13, console B14, motor A15, screw hole A16, walking track C17, motor B18, walking track D19, wheels 20, shaft A21, shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com