Multifunctional scour-preventing jet flow drilling and joint-cutting spray head for coal bed

A multi-functional, coal seam technology, applied in the direction of drilling with liquid/gas jets, etc., can solve the problems of large volume of forced rotating nozzles, unsuitable mining engineering, and high jet pressure requirements, and achieves weakening of coal body stress, good pressure relief effect, The effect of jet blowing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

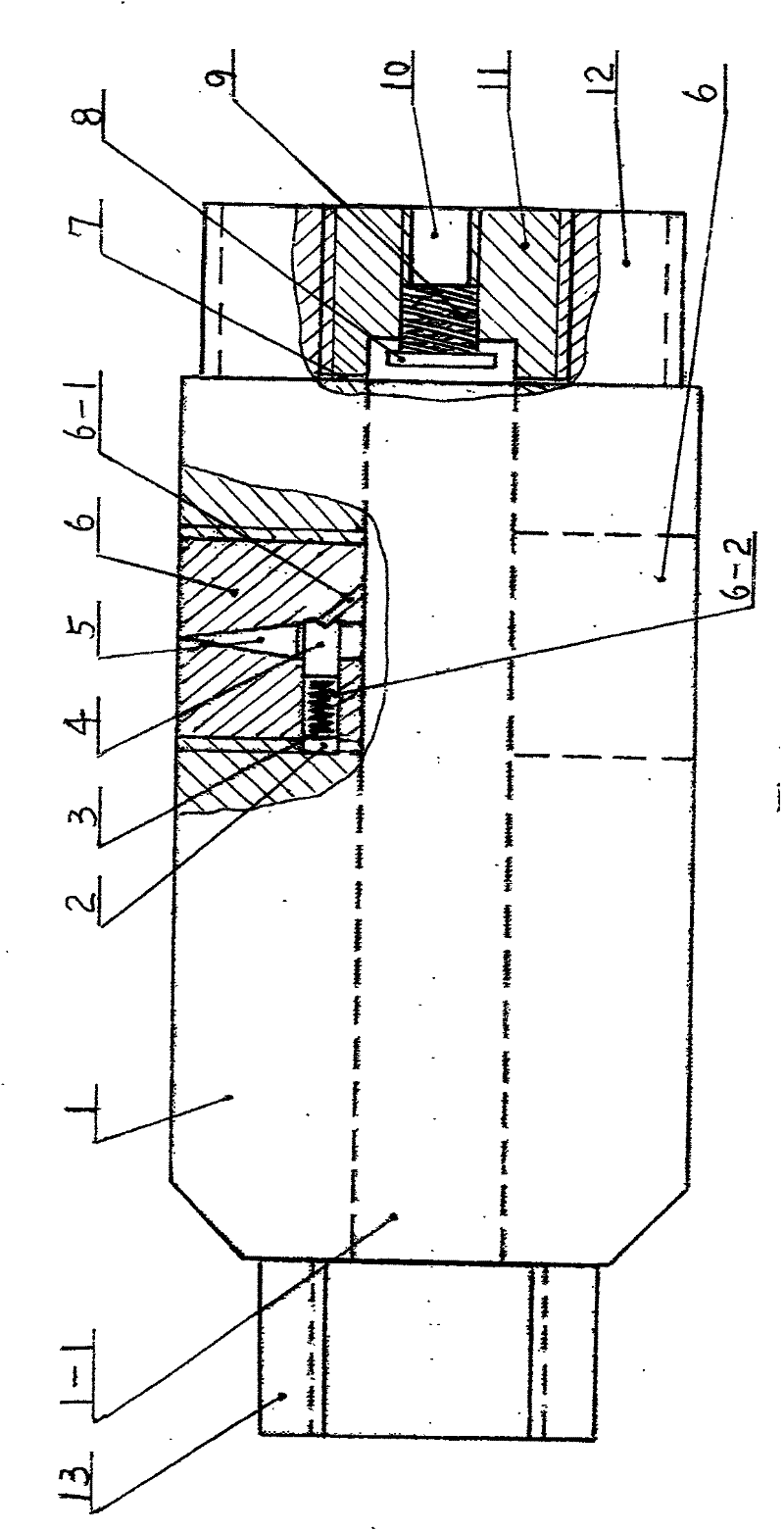

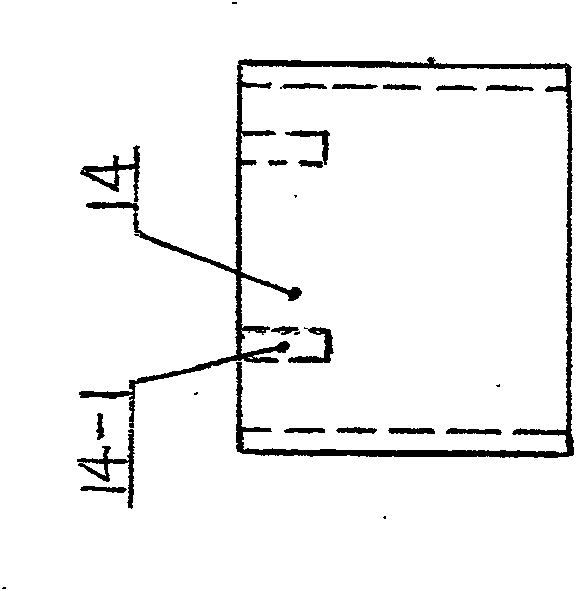

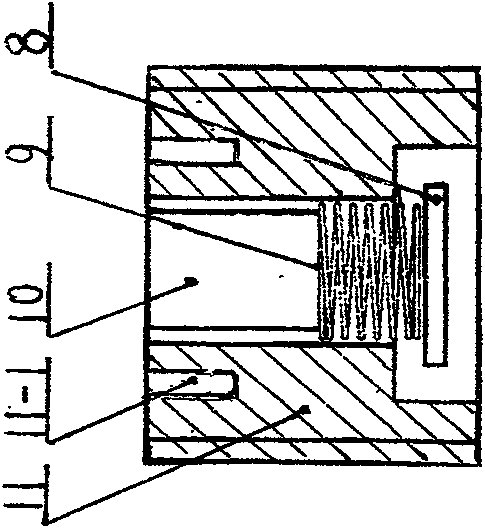

[0013] Examples, see attached Figure 1~4 , the outer sleeve 1 of the multi-functional coal seam anti-shock jet drilling slitting nozzle is fixedly connected to the drill pipe 13 at the left end, and the drill pipe 12 is fixedly connected to the right end. The drill pipe 13 is provided with internal threads, and the drill pipe 12 is provided with external threads. The center of the connecting body 12 is connected with a low-pressure water outlet control valve body 11 with an internal thread. The center of the low-pressure water control valve body 11 is provided with a water outlet hole 10. A step is arranged in the water outlet hole 10 and a low-pressure water outlet control spring 9 is installed. The left end of the low-pressure water outlet control spring 9 is connected to a Slider 8, water outlet hole 10 communicates with the water flow hole 1-1 in the center of outer sleeve 1. A gasket 7 is installed at the joint between the low-pressure water outlet control valve body 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com