Reciprocating sealed compressor

A compressor and sealed technology, which is applied in mechanical equipment, variable displacement pump components, machines/engines, etc., can solve problems such as vibration, high noise, high cost, and large air flow pulsation, and achieve good noise reduction effect and low manufacturing cost. Low, small air pulsation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

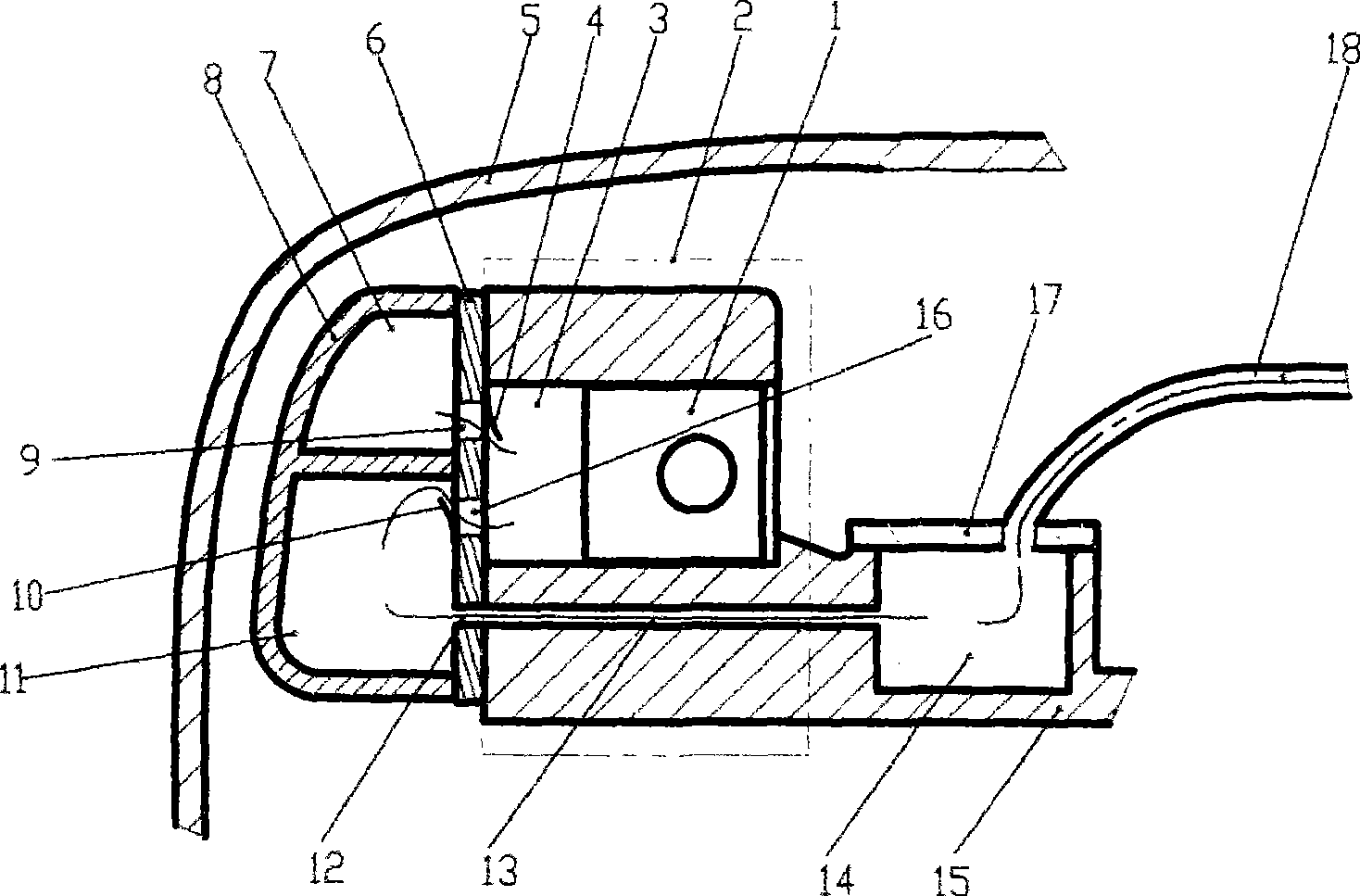

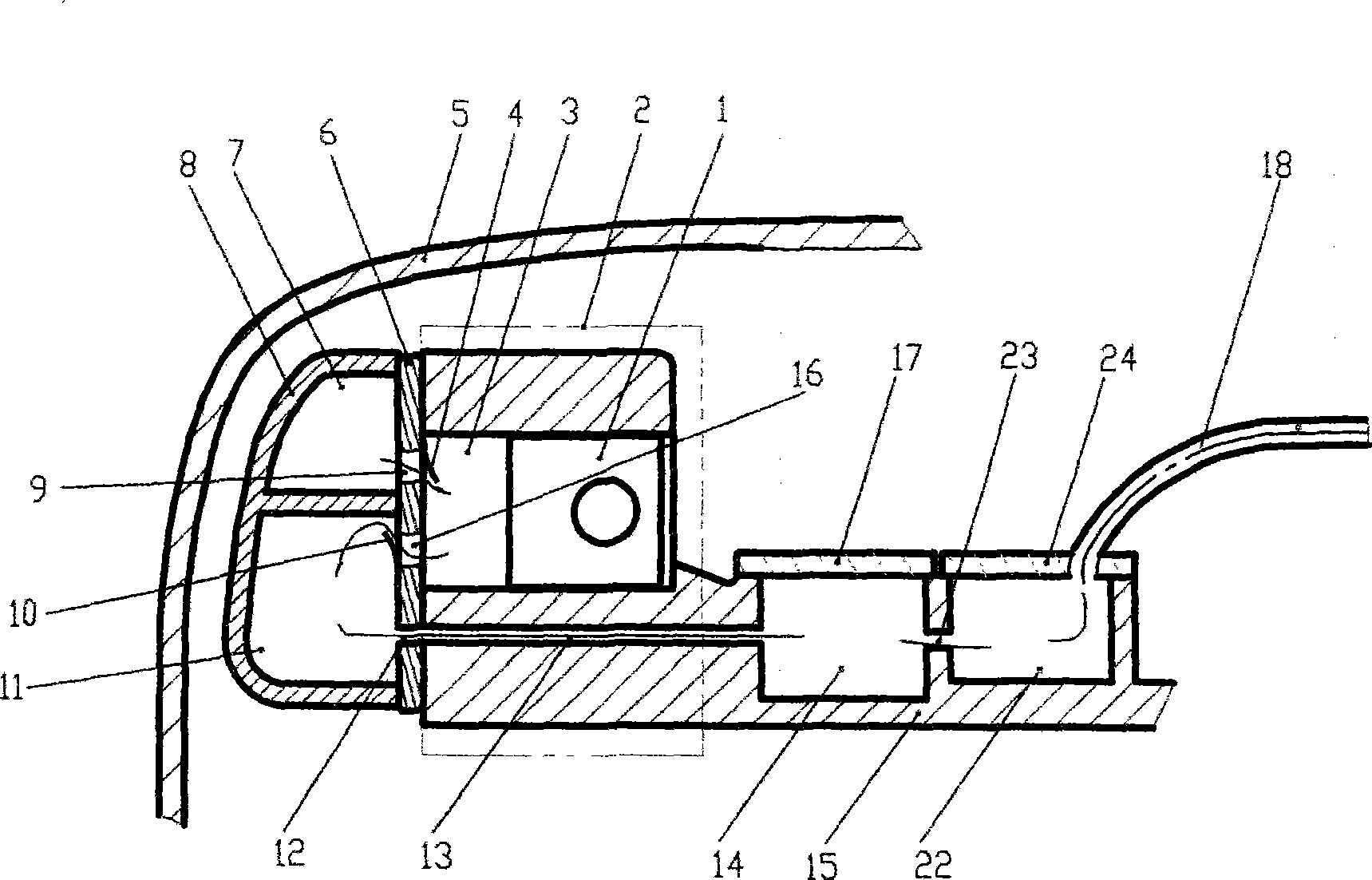

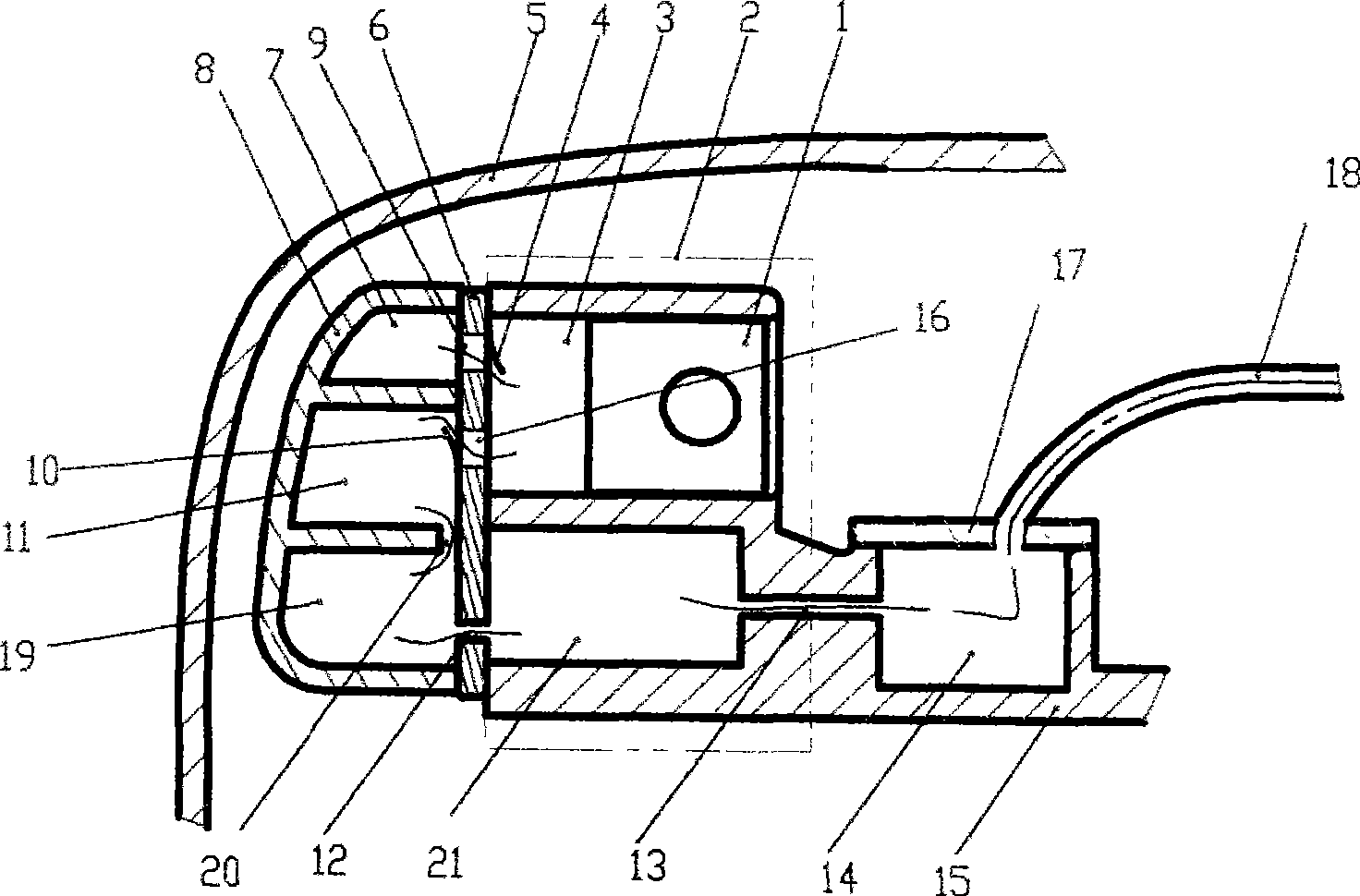

[0023] refer to image 3 , Fig. 4 and Fig. 5, a kind of reciprocating hermetic compressor provided by the present invention, it has the sealing casing that is made up of lower casing 50 and upper casing 5, has in the sealing casing that is made up of motor stator 32 and motor rotor 35 The motor, the gas compression device and exhaust system driven by the above-mentioned motor, a cylinder block 15 fixes the motor, the gas compression device and the exhaust system and is installed and connected with the lower casing 50 of the sealed shell by a spring 51, and the gas compression device includes Cylinder 3, valve plate 6, piston 1, piston connecting rod 31, comprise the cylinder head 2 of cylinder 3 and cylinder block 15 conjoined body, cylinder block 15 middle parts establish crankshaft installation hole, crankshaft 36 passes crankshaft installation hole, crankshaft 36 One end has an eccentric shaft 33, the piston connecting rod 31 connects the eccentric shaft 33 and the piston 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com