Flat LED daylight lamp

A technology of LED fluorescent lamps and LED light sources, which is applied in the direction of light sources, electric light sources, point light sources, etc., can solve the problems of difficult realization of LED fluorescent lamps, low production efficiency, difficult product assembly and maintenance, etc., and achieves easy assembly and maintenance, saving Good power and lighting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

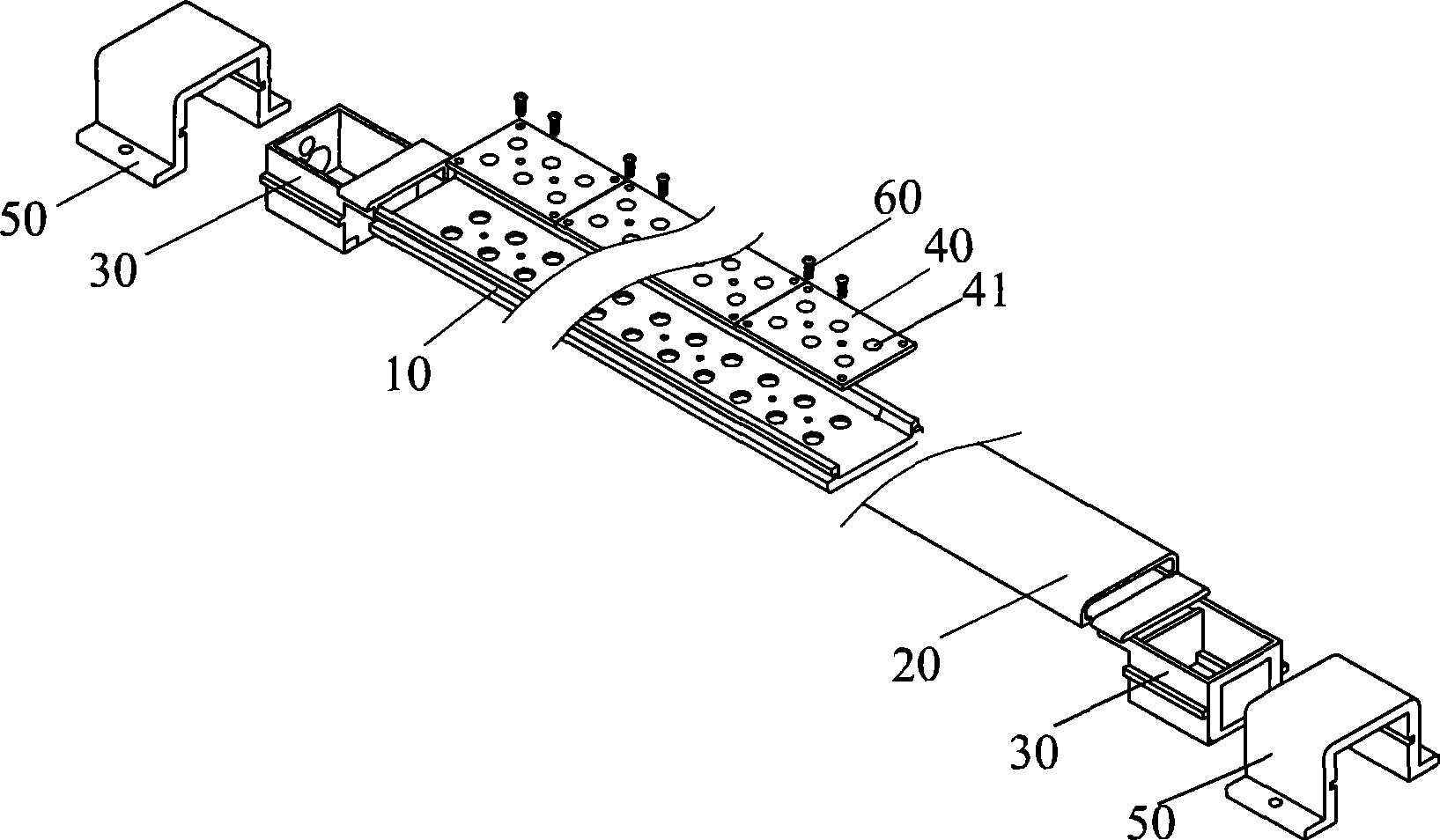

[0025] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a flat-panel LED fluorescent lamp. Due to the slidable fit of the slideway and the sliding body, the assembly or disassembly of the components can be realized by sliding and pushing in, the structure is simple, and the production and assembly process is simplified. Easier to assemble and repair.

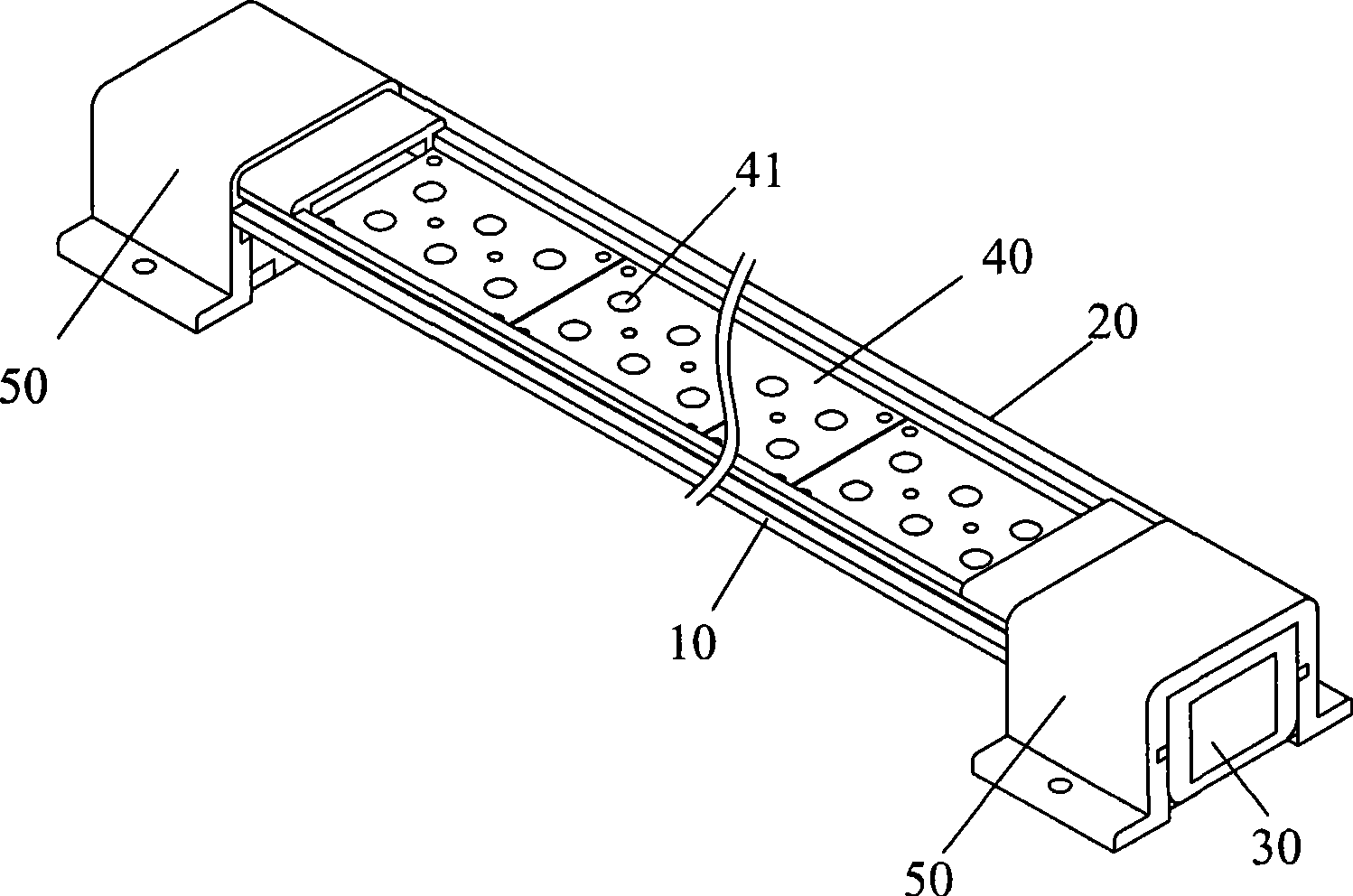

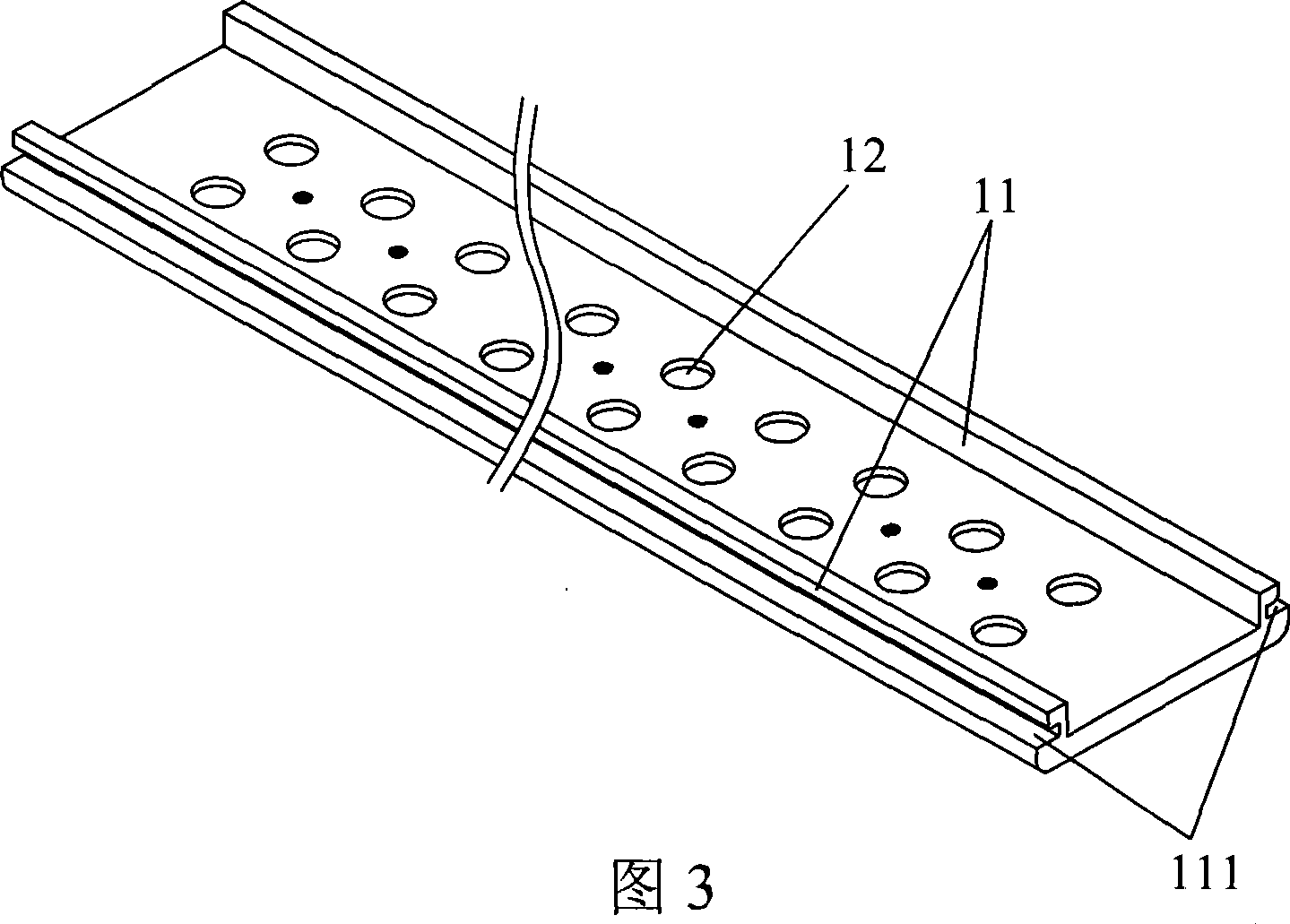

[0026] refer to Figure 1-8 , describes the first preferred embodiment of the present invention. First please refer to figure 1 and figure 2 , the flat LED fluorescent lamp of the present invention comprises LED41, the LED light source board 40 that installs said LED41, the heat dissipation base case 10 that carries said LED light source board 40, transparent cover 20, a pair of power supply fixing seats 30 and a pair of fixing frames 50, so The transparent outer cover 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com