Fresh air unit with an air supplying and heat recovering device

A technology of fresh air treatment unit and heat recovery device, which is applied in the energy recovery system of ventilation and heating, household heating, heating method, etc., can solve the problems of high energy consumption, offset of cold and heat, etc. Low cost and the effect of increasing dew point temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

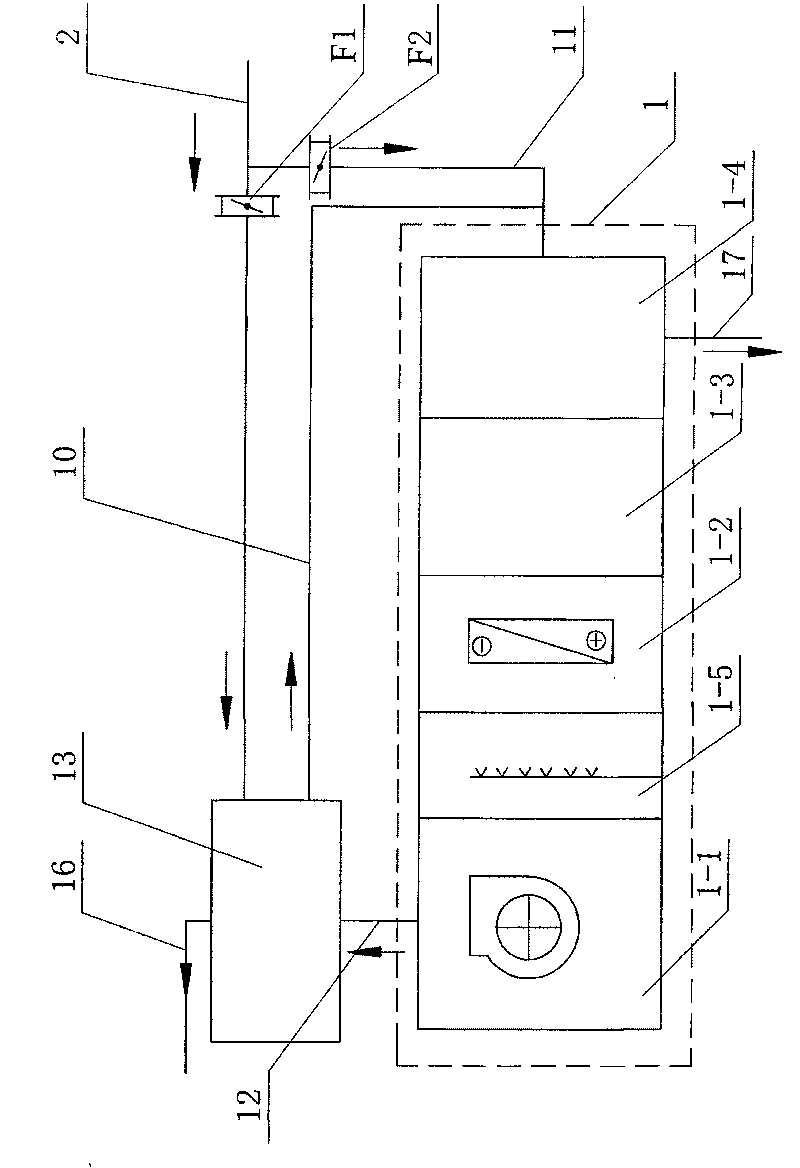

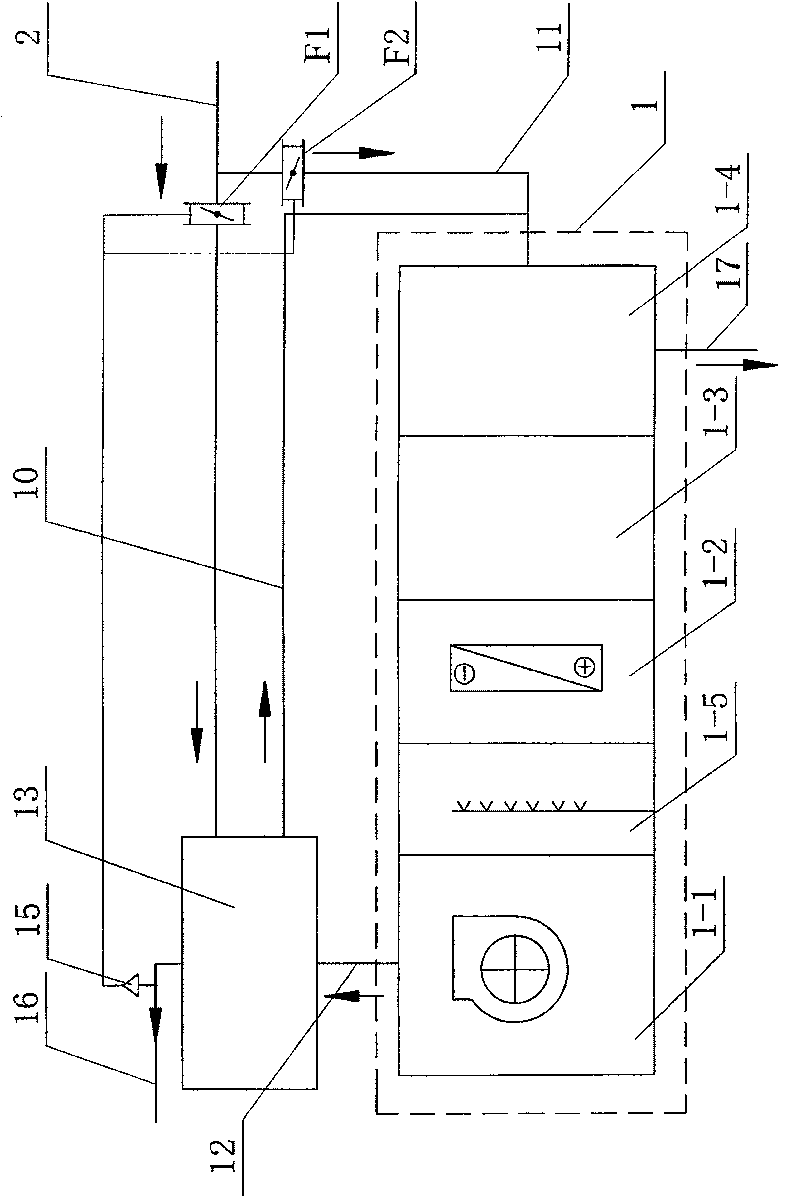

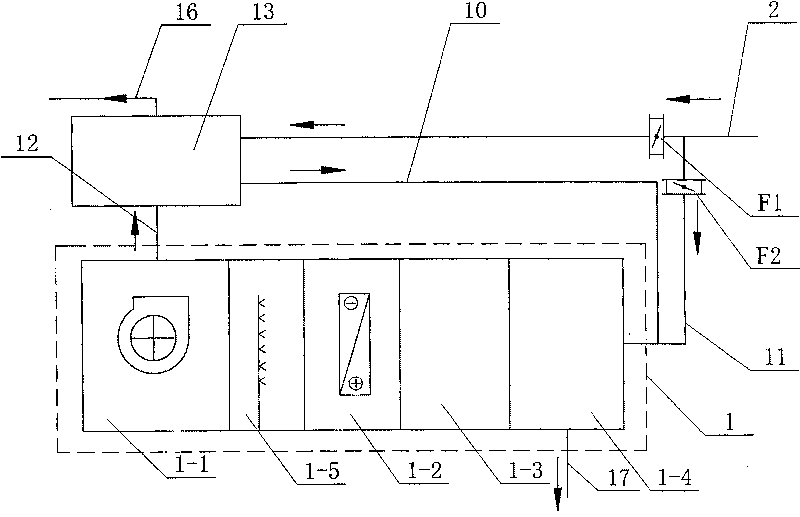

[0007] Specific implementation mode one: as figure 1 As shown, the fresh air processing unit with air supply heat recovery device described in this embodiment includes a fresh air processor 1, a fresh air pipeline 2, a first air volume regulating valve F1, a second air volume regulating valve F2, a first connecting Pipeline 10, second connecting pipeline 11 and third connecting pipeline 12, the fresh air processor 1 is composed of air supply section 1-1, humidification section 1-5, surface cooling section 1-2, mixing Sections 1-3 and exhaust air heat recovery device 1-4; the fresh air processing unit also includes a supply air heat recovery device 13; one end of the fresh air pipeline 2 communicates with the supply air heat recovery device 13, and the first The two ends of the two connecting pipelines 11 communicate with the fresh air pipeline 2 and the exhaust air heat recovery device 1-4, and the two ends of the first connecting pipeline 10 communicate with the supply air he...

specific Embodiment approach 2

[0008] Specific implementation mode two: as figure 1 As shown, the second connecting pipeline (11) in this embodiment is a right-angle elbow. Such setting facilitates the connection with the fresh air processor 1 . Other components and connections are the same as those in the first embodiment.

[0009] The working principle of the present invention is (in combination with figure 2 Explanation): A part of the outdoor fresh air enters the supply air heat recovery device 13 (for supply air heat recovery) through the fresh air pipeline 2, and then enters the fresh air processor 1 through the first connecting pipeline 10 and the second connecting pipeline 11 Another part of the outdoor fresh air enters the exhaust heat recovery device 1-4 of the fresh air processor 1 through the second connecting pipeline 11 (for exhaust heat recovery). ), and then enters the mixing section 1-3 of the fresh air processor 1, and the mixed air passes through the surface cooling section 1-2, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com