Air-handling unit with air blast thermal recovery machine

A technology of air handling unit and heat recovery device, which is applied in the energy recovery system of ventilation and heating, using air flow as shielding, household heating, etc., can solve the problems of cold and heat offset, high energy consumption, etc., to solve the offset problem , Reduce system energy consumption, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

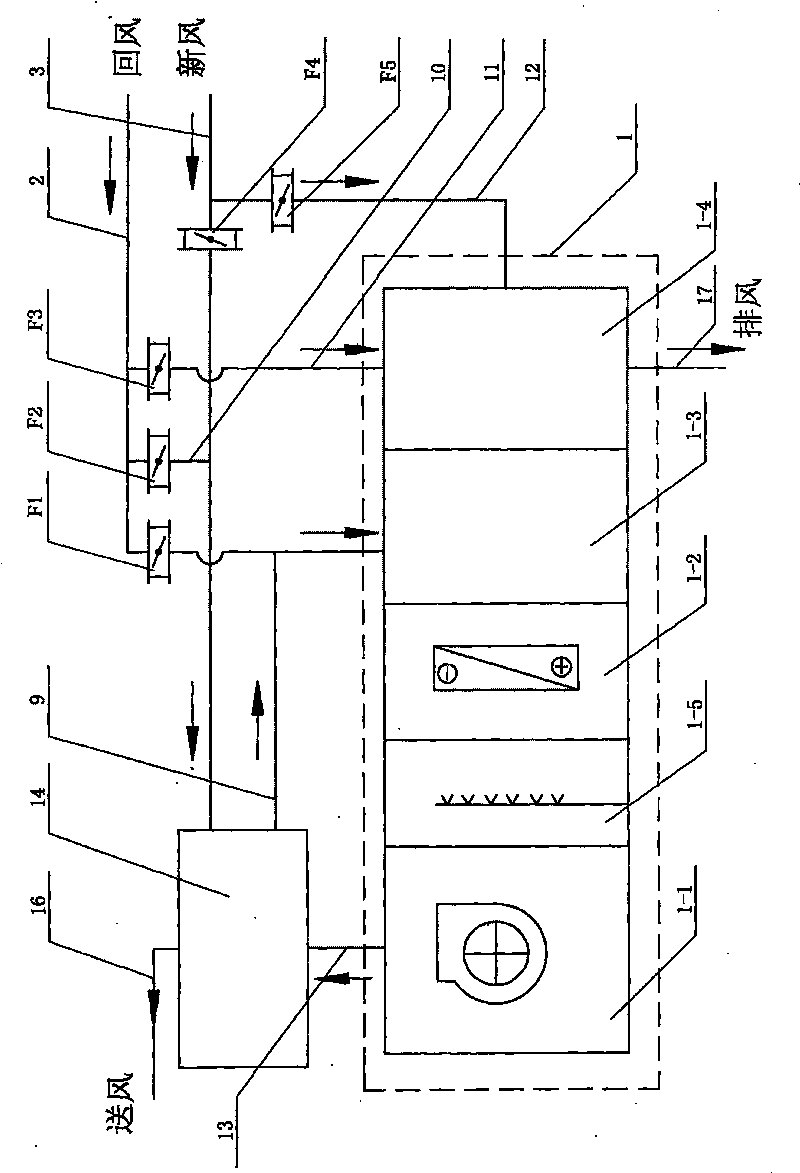

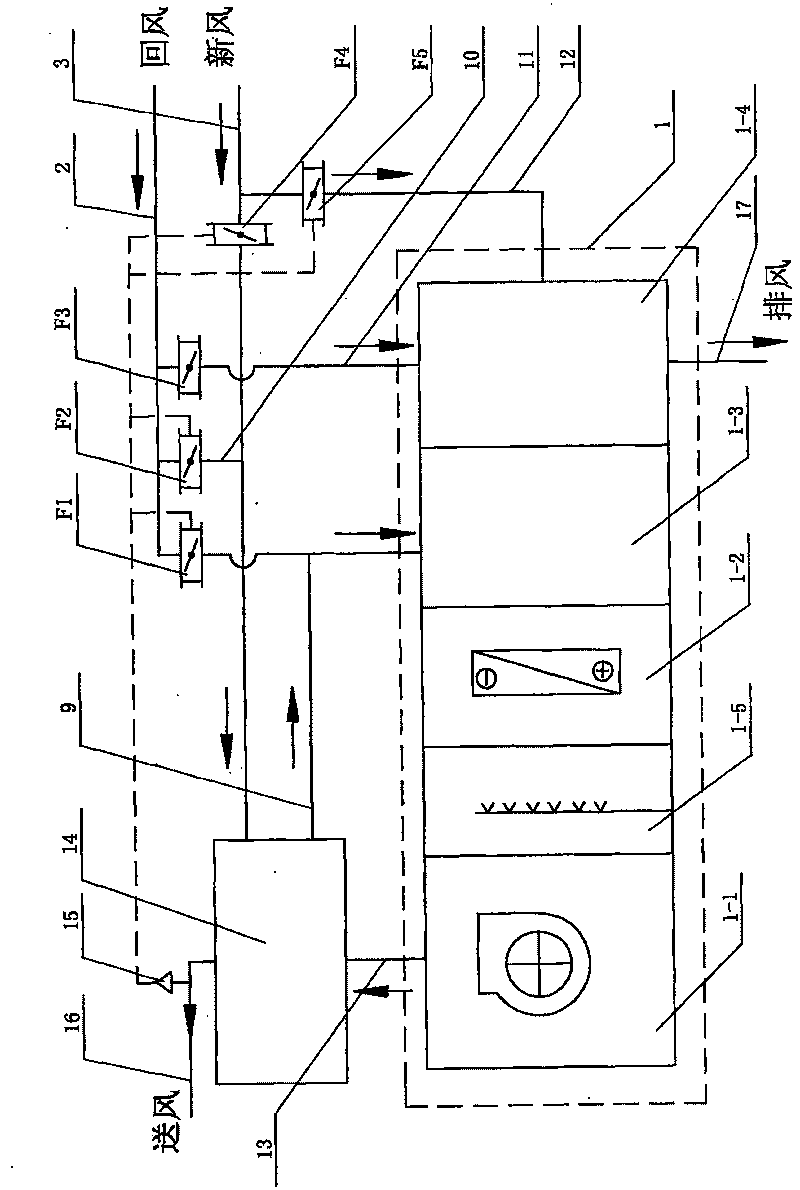

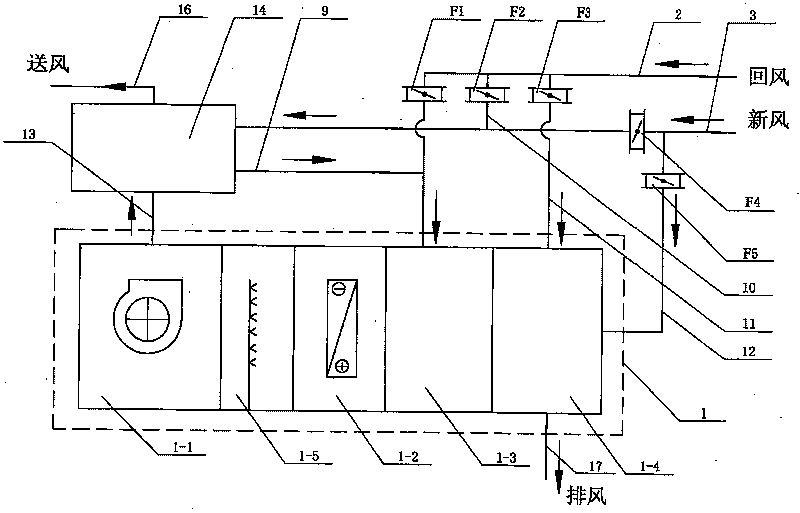

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment. The air handling unit in this embodiment includes an air conditioning processing unit 1, a return air pipeline 2, a fresh air pipeline 3, a first air volume regulating valve F1, a second air volume regulating valve F2, and a third air volume regulating valve F3. , the fourth air volume regulating valve F4, the fifth air volume regulating valve F5, the first connecting pipeline 9, the second connecting pipeline 10, the third connecting pipeline 11, the fifth connecting pipeline 12 and the sixth connecting pipeline 13, The air conditioning treatment unit 1 is composed of an air supply section 1-1, a humidification section 1-5, a surface cooling section 1-2, a mixing section 1-3 and an exhaust heat recovery device 1-4 connected in series; the air The processing unit also includes an air supply heat recovery device 14; one end of the return air pipeline 2 communicates with the mixing section 1-3, o...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To describe this embodiment, the return air pipeline 2 and the fifth connecting pipeline 12 in this embodiment are both right-angle elbows. Such setting facilitates the connection with the air-conditioning processing unit 1 .

[0009] The working principle of the present invention is (in combination with figure 2 Explanation): If the fresh air volume is sufficient, the second air volume regulating valve F2 is closed, the first air volume regulating valve F1, the fourth air volume regulating valve F4 and the fifth air volume regulating valve F5 are opened, and a part of outdoor fresh air enters into the delivery system through the fresh air pipeline 3 In the air heat recovery device 14 (for air supply heat recovery), it enters the mixing section 1-3 of the air conditioning treatment unit 1 through the first connecting pipeline 9 and the return air pipeline 2; another part of outdoor fresh air passes through the fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com