Air processing unit based on air blast thermal recovery and energy step utilization

An air handling unit and heat recovery technology, applied in heat recovery systems, energy recovery systems that use air flow as shielding, ventilation and heating, etc., can solve problems such as increased system energy consumption, waste of energy quality, and low dew point. Achieve the effect of simple and reasonable system structure, reduce system energy consumption, and increase dew point temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

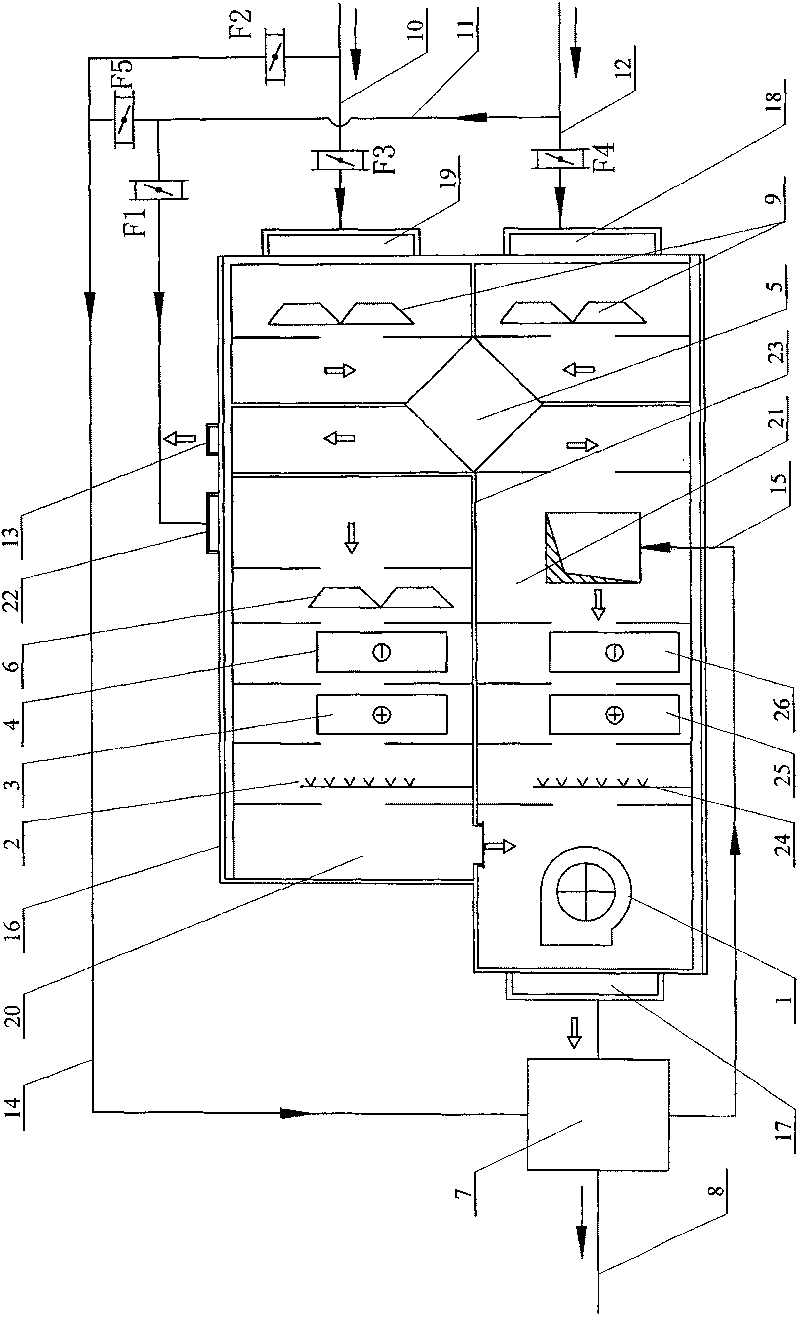

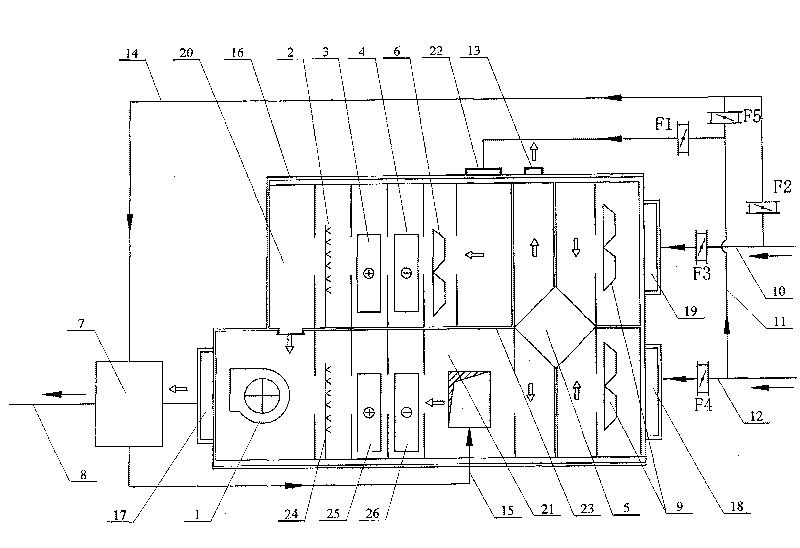

[0006] Specific implementation mode one: (see figure 1 ) This embodiment includes blower 1, exhaust air heat recovery device 5, air supply heat recovery device 7, air supply duct 8, fresh air inlet pipe 10, return air pipe 11, exhaust air pipe 12, exhaust air heat recovery device Air outlet 13, first pipeline 14, second pipeline 15, box body 16, air outlet 17, first air inlet 18, second air inlet 19, upper processing unit 20, lower processing unit 21, return air inlet 22, The partition 23, the first air volume regulating valve F1, the second air volume regulating valve F2, the third air volume regulating valve F3, the fourth air volume regulating valve F4 and the fifth air volume regulating valve F5, the air outlet 17 is fixed at the outlet of the box body 16 On the side, the blower 1 is arranged at the outlet in the box body 16, the first air inlet 18 and the second air inlet 19 are fixed side by side on the inlet side of the box body 16, and the exhaust heat recovery device ...

specific Embodiment approach 2

[0007] Specific implementation mode two: (see figure 1 ) In this embodiment, two initial-end filters 9 are added, and the two initial-end filters 9 are respectively arranged on the front side of the two air inlets of the exhaust air heat recovery device 5 in the box body 16 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0008] Specific implementation mode three: (see figure 1 ) In this embodiment, a return air filter 6 is added, and the return air filter 6 is arranged at the inlet end of the upper processing unit 20 in the box body 16 . Others are the same as in the second embodiment.

[0009] The filter added in the above-mentioned Embodiment 2 and Embodiment 3 is used to filter out impurities in the incoming air, so as to make the air fresher.

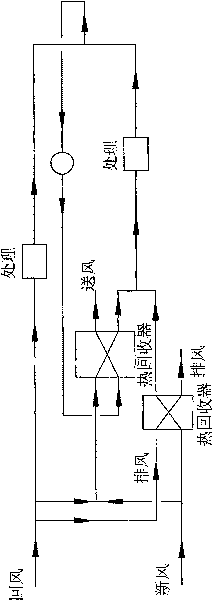

[0010] Air handling method: (see figure 1 and figure 2 ) If the fresh air volume is sufficient, the fifth air volume regulating valve F5 is closed. A part of the fresh air enters the air supply heat recovery device 7 through the second air volume regulating valve F2 for supply air heat recovery, and another part of the fresh air enters the exhaust air heat recovery section through the third air volume regulating valve F3 for exhaust air heat recovery, and then is combined with the recovered heat Part of the fresh air is mixed and treated togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com