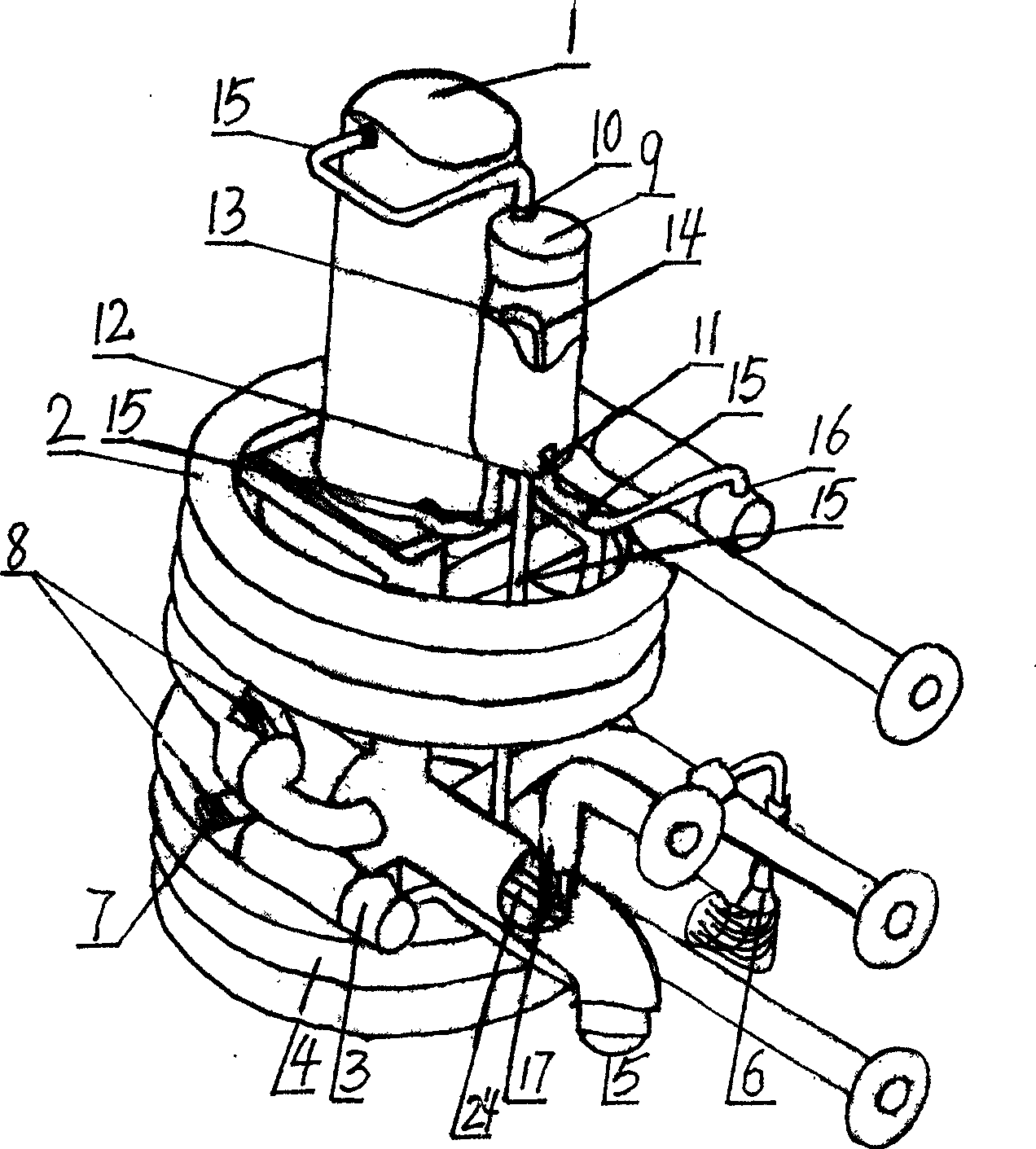

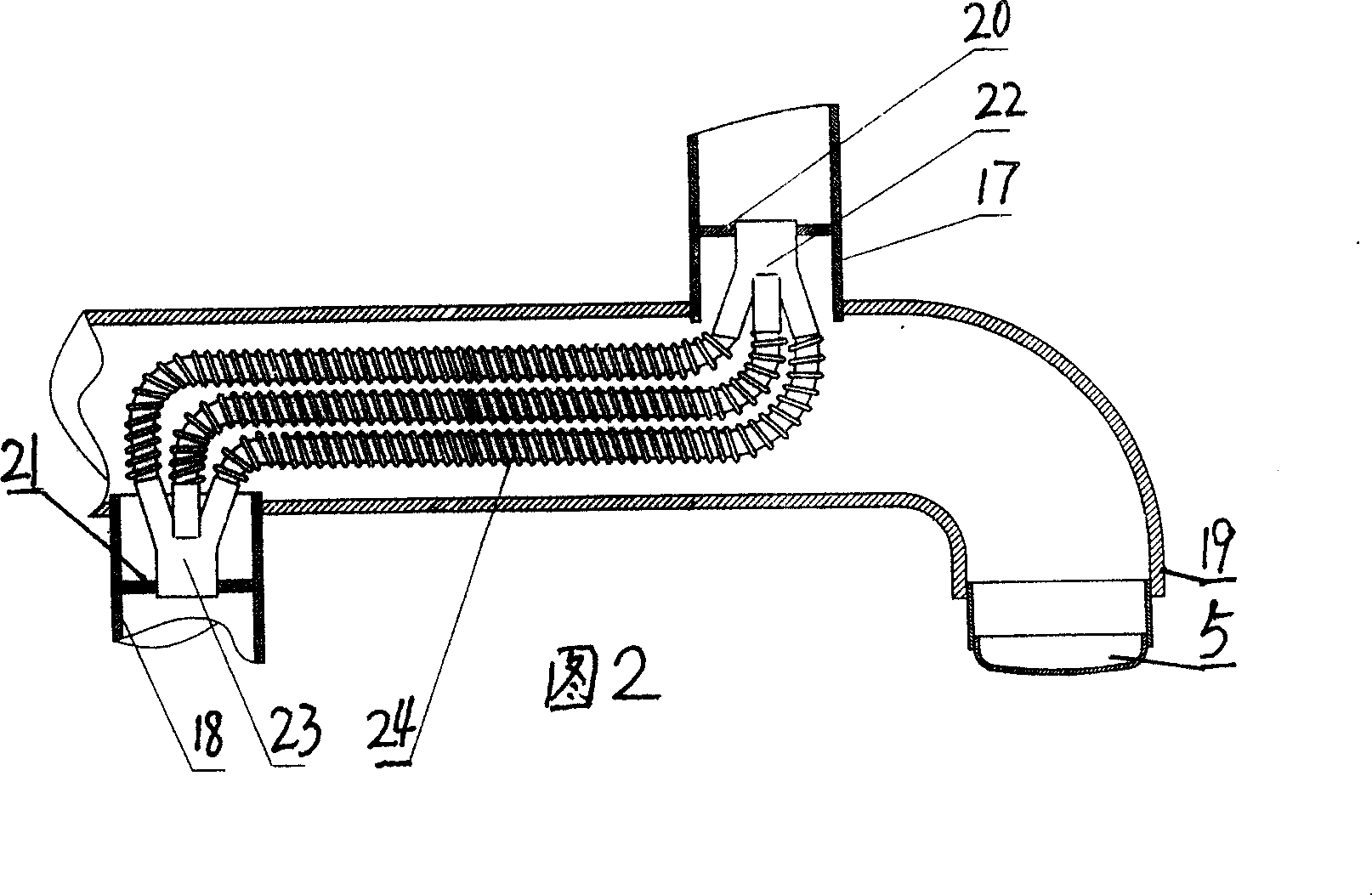

Flexible fluid-directing double-spiral-sleeve type heat exchanger

A double-helix, casing-type technology, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve the problems of high heat exchange tube consumables, which cannot meet the needs of energy saving, efficiency increase, and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A flexible diversion double helix casing heat exchanger, including a compressor 1, a spiral casing condenser 2 with an inlet 16 connected to the compressor 1, and a gas collector at the end connected to the compressor 1 The spiral casing evaporator 4 of the barrel 3, the collecting barrel 5 connected with the end of the spiral casing condenser 2; the collecting barrel 5 communicates with the spiral casing evaporator 4 through a liquid separator 6; The structures of the tube-shaped condenser 2 and the spiral-tube evaporator 4 both include tube sleeves, and several thin heat exchange tubes 7 that are sheathed in the tube sleeves; the outer walls of the thin heat exchange tubes 7 are provided with flexible flow guides at intervals 8. Both the spiral sleeve condenser 2 and the spiral sleeve evaporator 4 communicate with the compressor 1 through a heat exchanger; the heat exchanger structure includes: an outer casing 9, and an upper exhaust port 10 on the top of the outer cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com