Seamless assembly large screen displayed with multi-unit image and assembly method thereof

An image display and seamless technology, applied in the direction of static indicators, instruments, identification devices, etc., can solve the problems of different aging degrees, high production costs, and incapable of mass production, and achieve stable quality, reduce production costs, and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing of description:

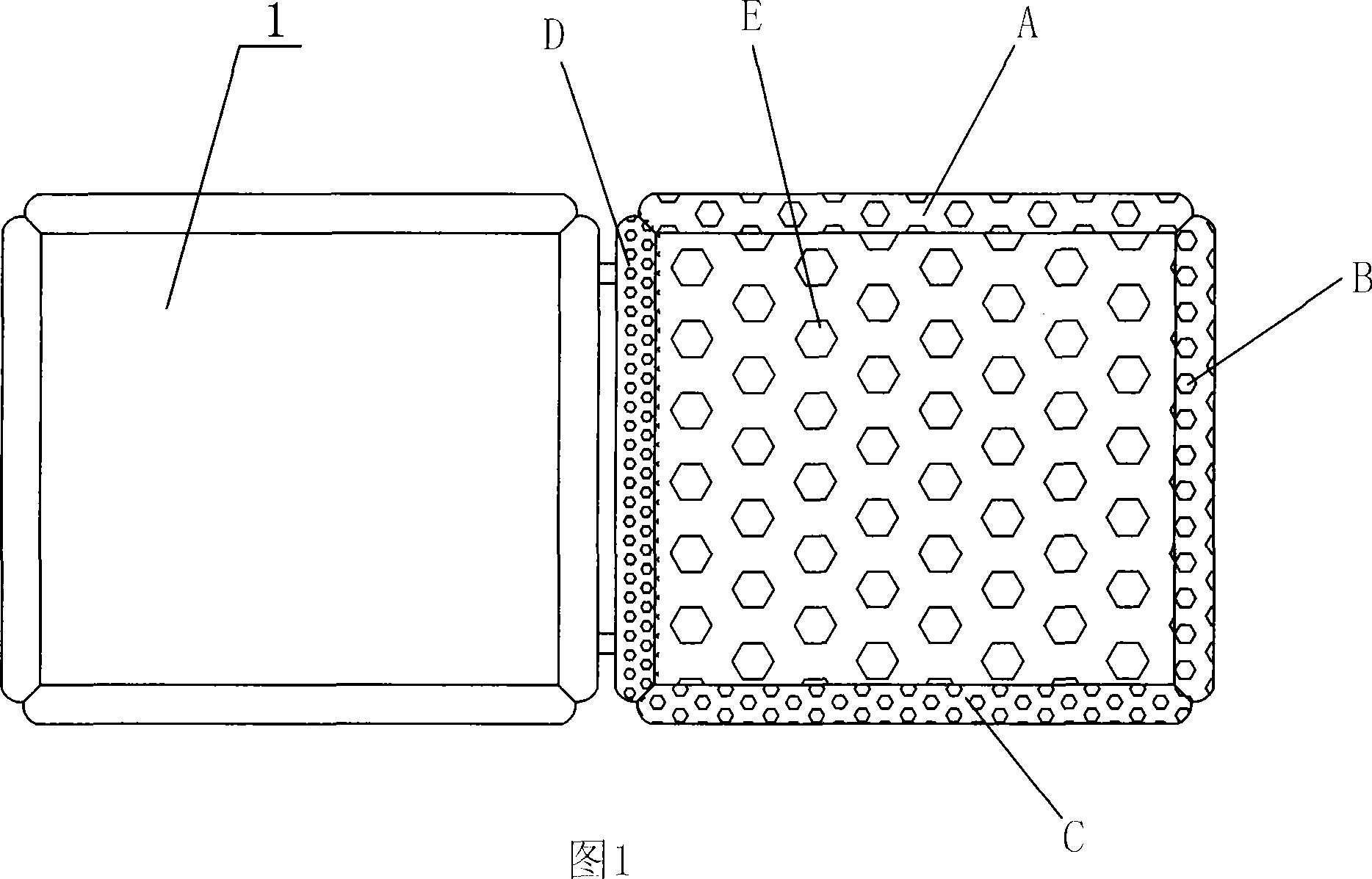

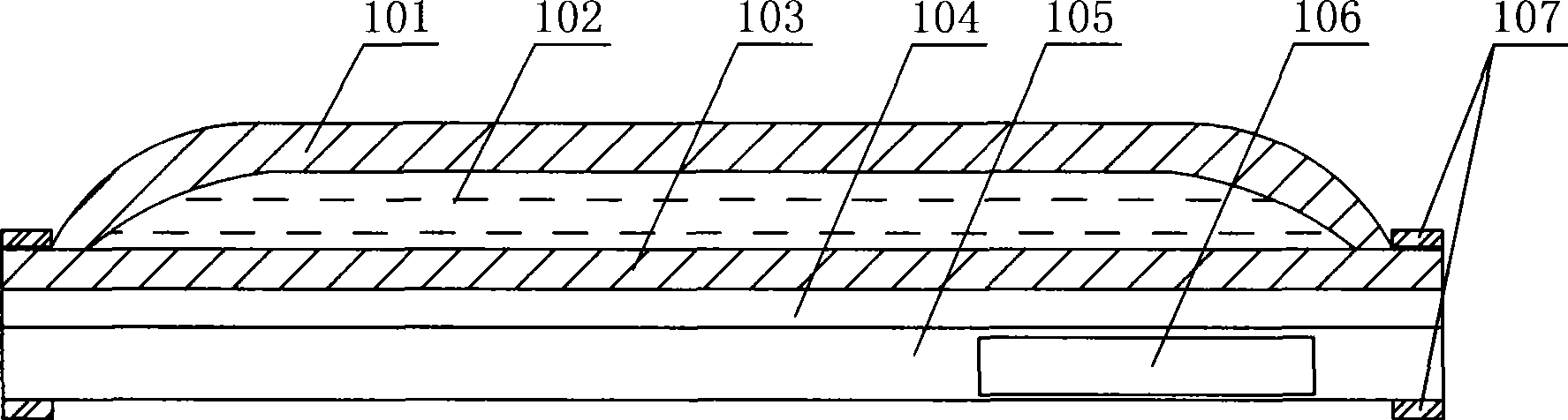

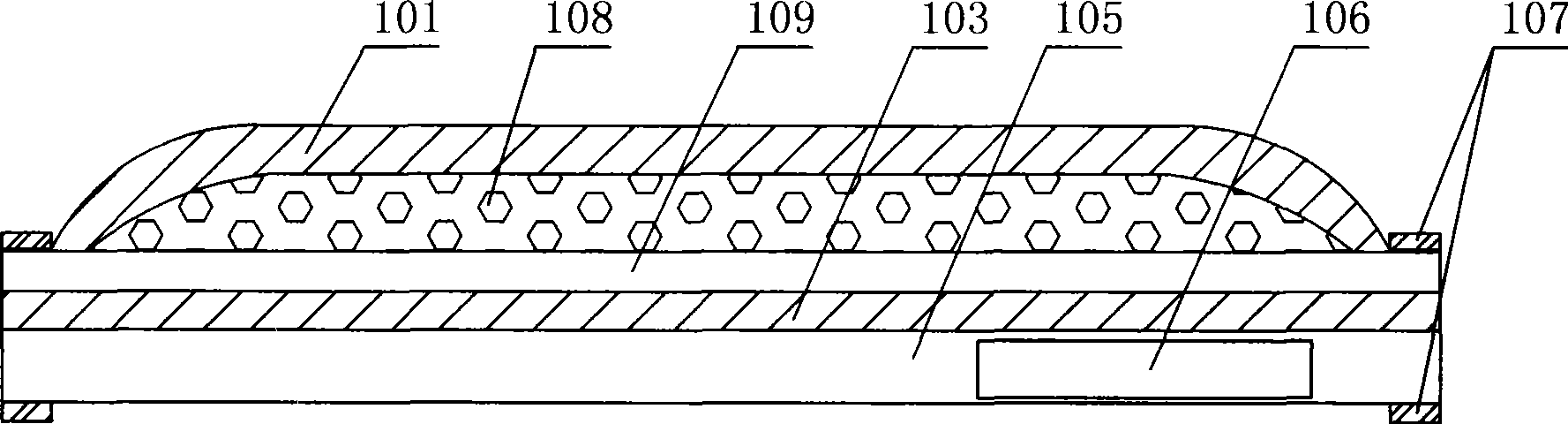

[0024] As shown in the figure, the seamless splicing large screen for multi-unit image display is formed by splicing a group of display units 1. The main surface of the surface glass substrate 101 of the display unit 1 is a planar structure, and the edge surfaces of the surface glass substrate 101 are of the same specification. arc-shaped structure, the arc surfaces of adjacent sides of each display unit 1 are symmetrical along the joint center, and each display unit 1 is equipped with an image corrector 106 for accessing image input data. Depending on the installation location, the surface glass substrate 101 may be an arc-shaped structure with four side edge surfaces of the same specification, or an arc-shaped structure with two side edge surfaces of the same specification. The arc of the edge arc of the surface glass substrate 101 can be within a range of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com