Manufacturing method of double diffusion field effect transistor

A technology of field effect transistors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., capable of solving large saturation current, rapid drop in device breakdown voltage, saturation current and breakdown voltage of double diffused field effect transistors It is difficult to optimize and other issues to achieve the effect of increasing the saturation current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

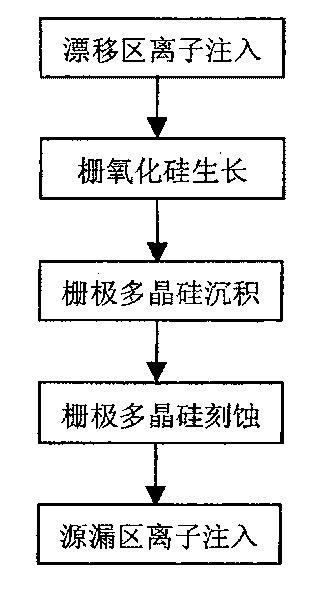

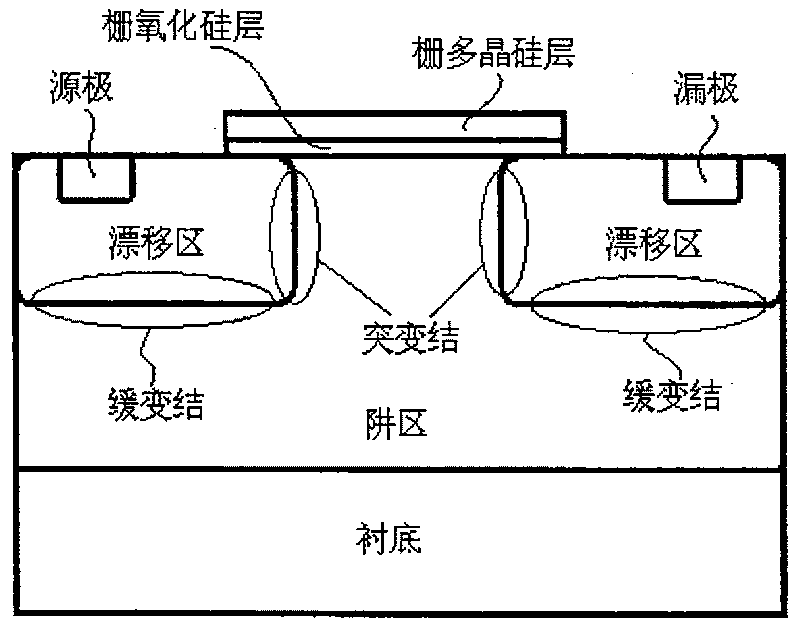

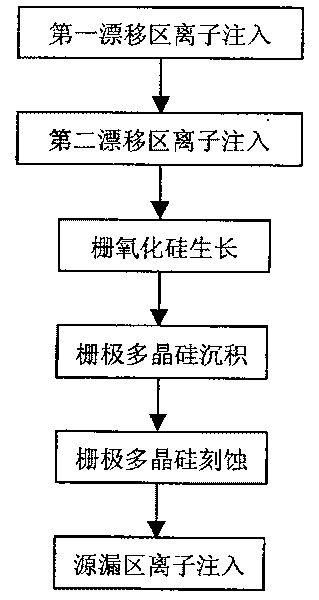

[0025] In one embodiment, such as image 3 Shown, method of the present invention comprises the following steps:

[0026] The first step is to carry out ion implantation on the silicon substrate to form a well region. Those skilled in the art should know that if the transistor to be manufactured is an N-type transistor, the ions to be implanted should be boron ions; The transistor to be manufactured is a P-type transistor, and the ions to be implanted at this time should be phosphorous ions.

[0027] In the second step, the first selective ion implantation is performed at the position of the well region of the silicon substrate to form the first drift region, and the cross-sectional structure at this time is as follows Figure 4a shown. Those skilled in the art should know that if the transistor to be manufactured is an N-type transistor, the implanted ions should be phosphorus ions at this time; and if the transistor to be manufactured is a P-type transistor, the implanted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com