Flexible field electron emission cathode material based on three-dimensional VS2/Zno composite nano-structure and preparation method thereof

A technology of composite nanostructure and field electron emission, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve problems such as the research and application of nanosheets and ZnO nanoparticle heterojunctions. , to achieve excellent application prospects, multiple launch positions, and resource-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

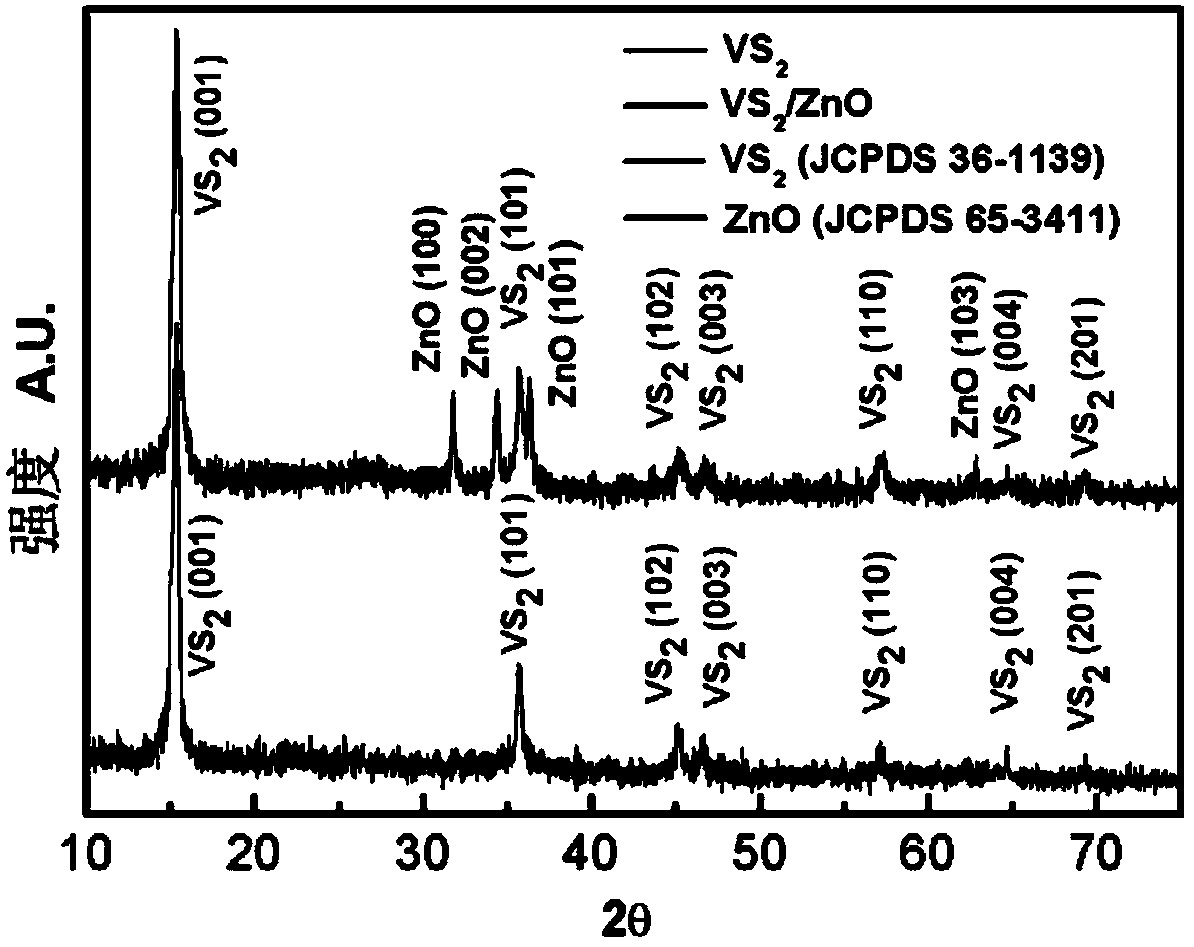

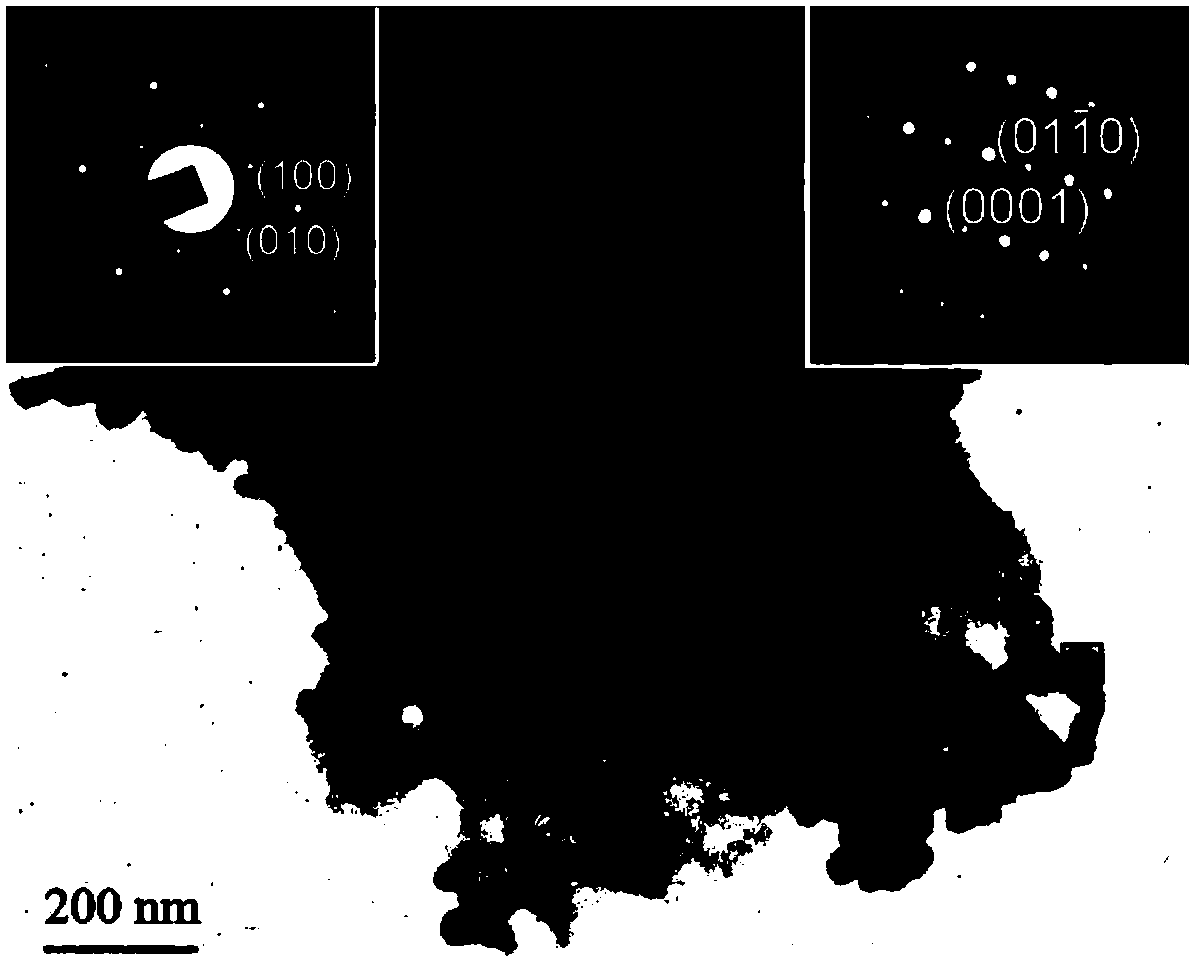

[0038] Three-dimensional VS of the present invention 2 The preparation method of / ZnO composite nanostructure comprises the steps:

[0039] (1) Utilize hydrothermal method, prepare VS respectively 2 Nanoflake suspensions and aqueous suspensions of ZnO nanoparticles;

[0040] (2) Drop the aforementioned ZnO nanoparticle suspension into the VS in the state of sonication 2 Suspension of nanoflakes, and ultrasonic treatment, after standing still, the precipitate was collected, washed and dried to obtain gray-black powder VS 2 / ZnO composite nanoparticles;

[0041] (3) under an inert gas protection atmosphere, the VS obtained in step (2) 2 / ZnO composite nanoparticles are annealed to obtain the three-dimensional VS as claimed in claim 1 2 / ZnO composite nanostructures.

[0042] The present invention based on PET three-dimensional VS 2 The preparation method of the flexible field electron emission material of / ZnO composite nanostructure comprises the following steps:

[0043...

Embodiment 1

[0051] 1. Clean the 0.2mm thick reinforced PET film and cut it into small pieces of about 2cm×2cm;

[0052] 2. Deposit about 20nm thick gold film on the surface of PET film by sputtering method and lead out the electrode leads;

[0053] 3. Add 10mmol sodium orthovanadate and 50mmol thioacetamide powder to 100mL deionized water, and stir for 30 minutes;

[0054] 4. Wash the Teflon reactor with a capacity of 100mL, and slowly add the above-mentioned mixed solution;

[0055] 5. Put the sealed reaction kettle into the heating furnace, set the furnace temperature to 170°C, and the reaction time to 16 hours;

[0056] 6. After the reaction, cool down to room temperature naturally, pour out the reaction solution, and take out the precipitated gray-black powder. After being washed several times with ethanol and deionized water, it was sonicated in 50 mL of deionized water for 1 hour. get black vs 2 The suspension was sealed and allowed to stand for 24 hours, and then 25 mL of the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com