Electrophotographic photosensitive body, image forming device, and electrophotographic cartridge

A technology of electrophotography and photoreceptor, applied in optics, electrography, instruments, etc., to achieve the effects of low residual potential, high-quality images, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

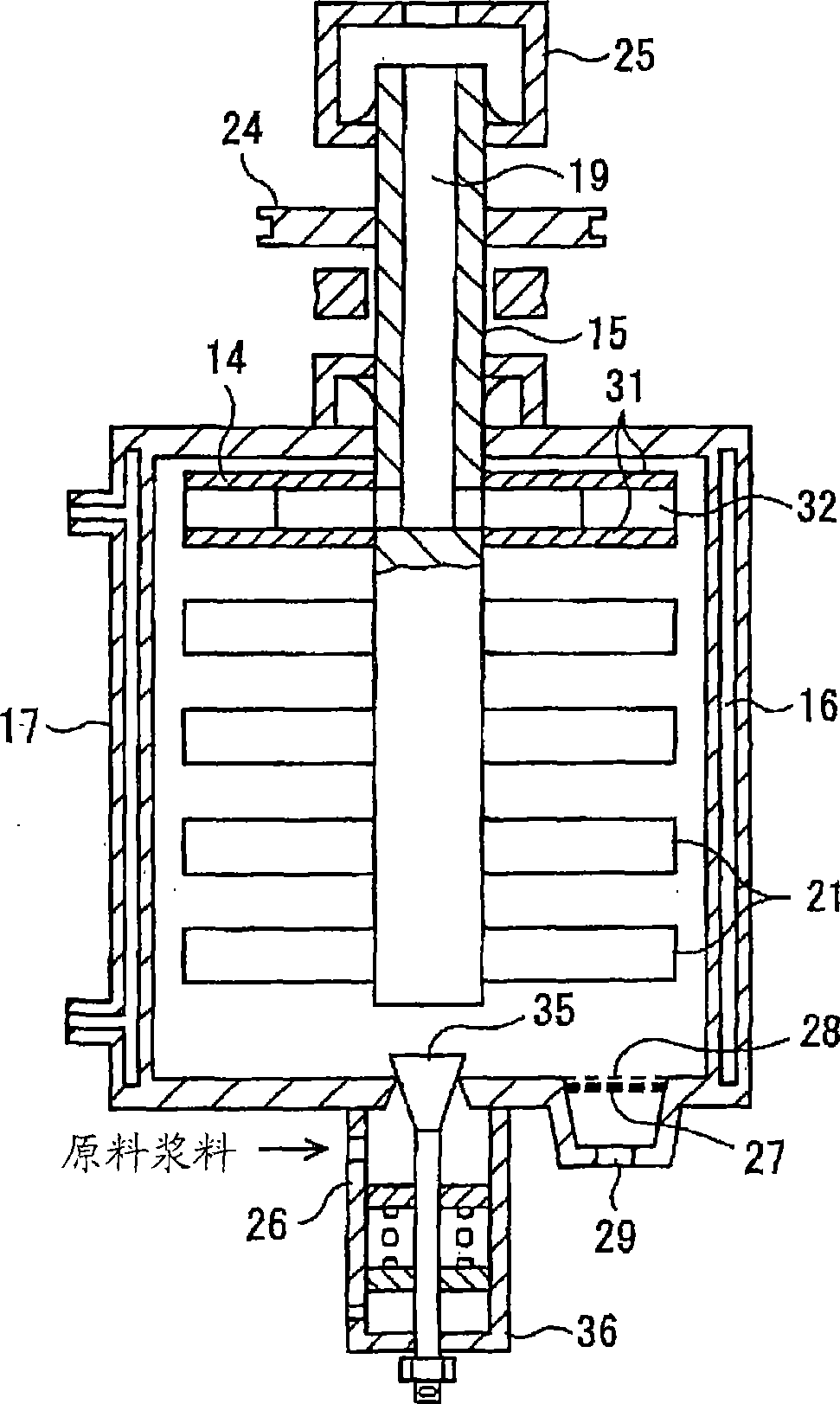

[0484] [Coating solution for undercoat layer]

[0485] Using a Henschel mixer, rutile-type titanium dioxide having an average primary particle diameter of 40 nm ("TTO55N" manufactured by Ishihara Sangyo Co., Ltd.) and 3% by weight of methyldimethoxysilane (Toshiba Silicone) were mixed with respect to the titanium dioxide. company "TSL8117") to obtain surface-treated titanium dioxide, 50 parts of the obtained surface-treated titanium dioxide and 120 parts of methanol were mixed to obtain a raw material slurry, and zirconia beads with a diameter of about 100 μm (YTZ manufactured by NIKKATO Co., Ltd. ) as the dispersion medium, using the ULTRAAPEX MILL (UAM-015 type) manufactured by Shou Kogyo Co., Ltd. with a mill volume of about 0.15L, under the state of liquid circulation at the rotor peripheral speed of 10 m / s and the liquid flow rate of 10 kg / hour, 1 kg of the The raw material slurry was dispersed for 1 hour to prepare a titanium dioxide dispersion.

[0486] Heat the above-...

Embodiment 2

[0503] A photoreceptor E2 was obtained in the same manner as in Example 1 except that the following compound (CT-2) was used instead of the above-mentioned compound (CT-1) as the charge-transporting substance.

[0504]

Embodiment 3

[0506] Photoreceptor E3 was obtained in the same manner as in Example 1 except that the following compound (CT-3) was used instead of the above-mentioned compound (CT-1) as the charge-transporting substance.

[0507]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com