Ochre forging method

A process method and ochre technology, applied in the field of traditional Chinese medicine, can solve the problems of time-consuming, labor-intensive production, and uneven quality, and achieve the effect of solving uneven quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] An optimum calcining process for ochre, characterized in that the process steps are as follows

[0065] (1) Break ocher into small pieces of 4-5 mm, wash, dry, and place the ochre in a crucible with a thickness of 2 cm;

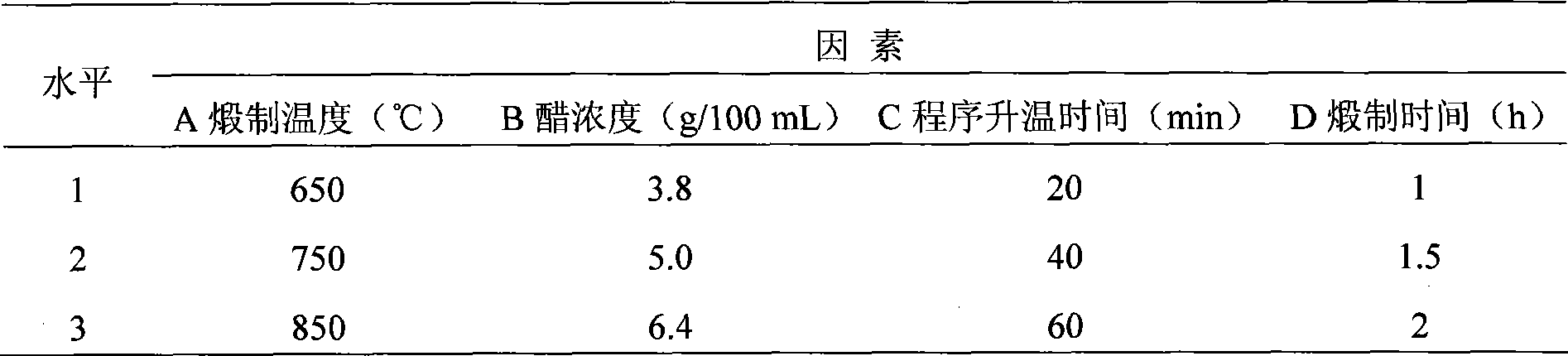

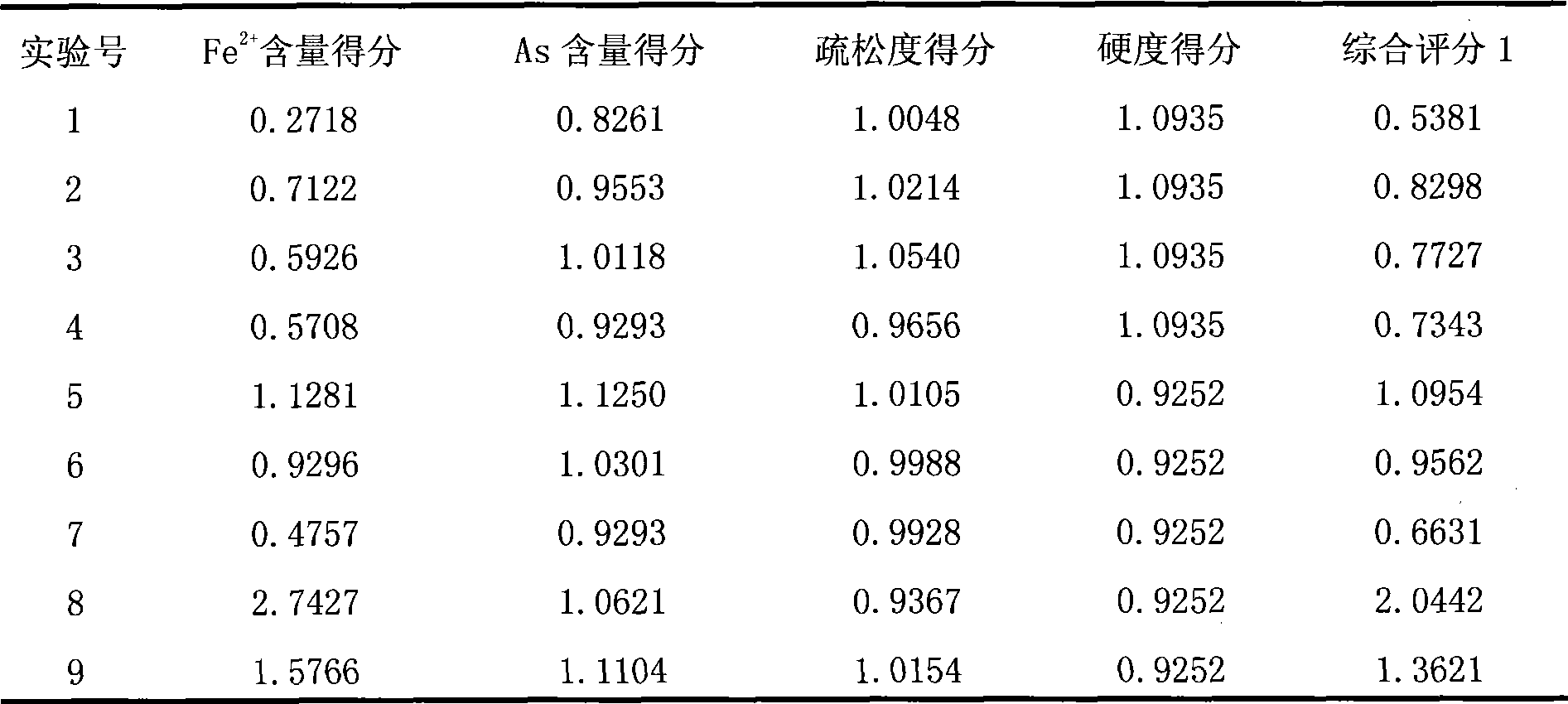

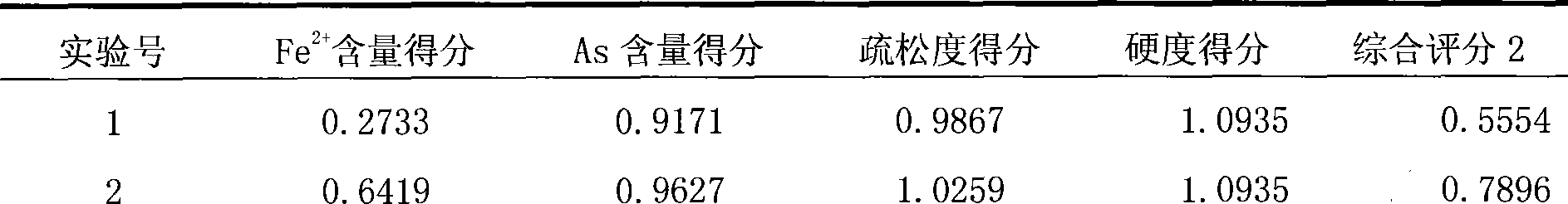

[0066] (2) According to ocher calcining temperature (650°C, 750°C, 850°C), vinegar concentration (3.8g / 100mL, 5.0g / 100mL, 6.4g / 100mL), calcining time (1h, 1.5h, 2h), Program heating time (20min, 40min, 60min) four investigation factors, each factor takes 3 levels, choose L 9 (3 4 ) Orthogonal table arrangement test, according to the orthogonal test scheme, the ocher obtained in the previous step is calcined, and each test number is repeated 3 times (shown in Tables 2, 3, and 4);

[0067] (3) Determination of the relative hardness, porosity, and Fe in the decoction of calcined ochre obtained in the previous step 2+ The method of As content in content, water decoction is as follows:

[0068] ① Determination of relative hardness of calcined ochre by M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com